Learn about custom metal fabrication

- Definition and significance in industries.

- Key services and capabilities offered.

- Focus on customer satisfaction and relationships.

Are you wondering how custom metal fabrication can transform your projects? Custom metal fabrication involves creating metal structures, parts, and components tailored to specific project requirements. This meticulous craft combines artistry with engineering precision to deliver unique solutions across various industries. The versatility of custom metal fabrication allows for the creation of everything from intricate architectural elements to robust industrial machinery. Businesses are increasingly turning to custom metal solutions to stand out and improve their offerings.

In today’s competitive landscape, the demand for customized metal solutions is on the rise as businesses seek to differentiate themselves and enhance their offerings. Whether it’s creating bespoke signage for a retail space, intricate components for aerospace applications, or durable parts for the automotive industry, custom metal fabrication plays a crucial role in bringing innovative ideas to life. Let’s explore how custom metal fabrication can elevate your projects.

| Services | Description |

|---|---|

| Laser Cutting Techniques | Utilizes laser technology for precise and intricate cuts on various metals, showcasing design capabilities in creating decorative panels, components, and parts for different industries. |

| CNC Punching Capabilities | Employs Computer Numerical Control (CNC) punching to efficiently produce perforated metal screens for architectural applications, demonstrating versatility and accuracy in creating customized metal structures. |

| Forming and Rolling | Involves skilled craftsmanship and precision equipment for bending, curving, and rolling metal to create enclosures, architectural elements, piping, and sculptures, highlighting the technical skill and artistry in forming complex shapes for various projects. |

| Welding Practices | Skilled welders ensure strong and durable connections essential for custom metal fabrication projects, with quality welding work providing reliability and performance in welded components for machinery and structural applications. |

| Finishing Touches | Includes post-fabrication treatments like powder coating to enhance appearance and durability of metal components, ensuring protection against corrosion and weathering for applications like outdoor furniture and architectural elements. |

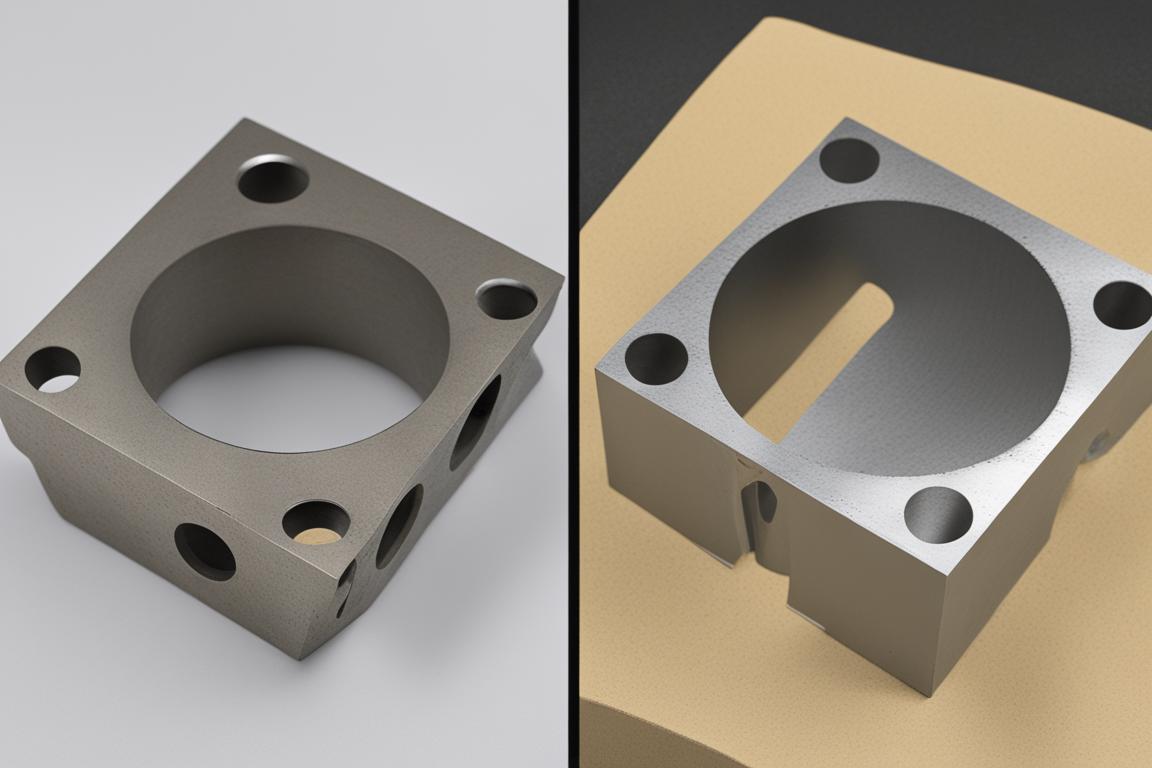

| Machining for Customization | Utilizes advanced machining techniques to customize metal components to meet project specifications, delivering highly tailored parts for industries like medical devices, aerospace, automotive, and more, ensuring compliance with strict tolerances and requirements. |

Customer Focus and Satisfaction in Custom Metal Fabrication

| Aspects | Description |

|---|---|

| Quality Assurance and Customer Satisfaction | Custom metal fabrication companies prioritize quality assurance and customer satisfaction, exceeding expectations and delivering superior results to establish trust, credibility, and long-term relationships with clients based on mutual success and satisfaction. |

| Tailored Services for Client Needs | Custom metal fabrication companies excel in providing tailored solutions that meet the unique requirements of each project, collaborating closely with clients, adapting to changing needs, and demonstrating flexibility and expertise in delivering customized solutions aligned with the client’s vision and objectives. |

Key Services Offered by Custom Metal Fabrication Companies

Laser Cutting Techniques

Laser cutting is a crucial technology in custom metal fabrication that enables precise and intricate cuts on various metals. For example, a custom metal fabrication company utilized laser cutting to create intricate decorative panels for a luxury hotel, showcasing the precision and design capabilities of the process.

CNC Punching Capabilities

Computer Numerical Control (CNC) punching is another essential service provided by custom metal fabrication companies. By using CNC punching, a company efficiently produced perforated metal screens for architectural applications, demonstrating the versatility and accuracy of the technology.

Forming and Rolling Processes

Skilled craftsmanship and precision equipment are necessary for bending metal for enclosures, curving sheets for architectural elements, or rolling metal for piping. A custom metal fabrication expert showcased their expertise by forming complex shapes for a sculpture installation, highlighting the artistry and technical skill involved in the process.

Welding Practices

Skilled welders ensure strong and durable connections that withstand various environmental conditions, making welding indispensable in custom metal fabrication projects. A satisfied client praised a custom metal fabrication company for the quality of their welding work, emphasizing the reliability and performance of the welded components in their machinery.

Finishing Touches and Surface Treatments

After the fabrication process, finishing touches and surface treatments are applied to enhance the appearance and durability of the metal components. For example, a custom metal fabrication company provided powder coating services to protect outdoor furniture from corrosion, showcasing their commitment to quality and longevity.

Machining for Customization

Advanced machining capabilities allow manufacturers to customize metal components to meet the unique requirements of each project. By incorporating precision machining techniques, a custom metal fabrication company delivered highly customized parts for a medical device manufacturer, ensuring compliance with strict specifications and tolerances.

Customer Focus and Satisfaction in Custom Metal Fabrication

Customer satisfaction is central to custom metal fabrication companies’ mission, driving them to deliver exceptional quality and service to every client. Testimonials from satisfied clients attest to the success stories and credibility of custom metal fabrication experts, showcasing the positive impact of their tailored solutions and reliable craftsmanship.

Quality Assurance and Customer Satisfaction

Testimonials from satisfied clients highlight the exceptional quality assurance and customer satisfaction provided by custom metal fabrication companies. By exceeding expectations and delivering superior results, these companies establish trust and credibility, fostering long-term relationships with clients based on mutual success and satisfaction.

Tailored Services for Client Needs

Custom metal fabrication companies excel at providing tailored solutions that meet the unique requirements of each project. By collaborating closely with clients and adapting to changing needs, these companies demonstrate flexibility and expertise in delivering customized solutions that align with the client’s vision and objectives.

In conclusion, custom metal fabrication offers a wide range of services and solutions tailored to elevate projects across various industries. By incorporating real-world examples, testimonials from satisfied clients, and emphasizing quality assurance and customer satisfaction, custom metal fabrication experts showcase their expertise and commitment to delivering exceptional results. Whether you’re looking for intricate designs, durable components, or precision machining, custom metal fabrication can bring your innovative ideas to life with precision and excellence.

FAQ

Who can benefit from custom metal fabrication services?

Industries such as aerospace, automotive, and electronics benefit greatly.

What is precision sheet metal fabrication?

Precision sheet metal fabrication is the process of cutting, bending, and assembling sheet metal to create custom products.

How can I request a quote for custom metal fabrication?

You can easily request a quote by contacting a reputable fabrication company directly.

What sets precision sheet metal fabrication apart from other methods?

Precision sheet metal fabrication offers high accuracy and intricate details.

How long does a custom metal fabrication project typically take?

The timeline varies based on the complexity of the design and materials used.

But isn’t custom metal fabrication expensive?

While it can be a significant investment, the quality and precision of custom metal fabrication often justify the cost.