In the realm of precision sheet metal fabrication, laser cutting stands out as a beacon of technological advancement and precision. At Atlas Manufacturing, we don’t just offer laser cutting services; we redefine what precision means in every cut, every design, and every project we undertake. Our dedicated approach combines state-of-the-art technology with unmatched expertise to deliver laser cutting services that set new standards in the industry.

What You’ll Learn About Laser Cutting

You will learn about laser cutting services, capabilities, materials, tolerances, and thickness.

– Laser cutting services provide precision cutting for various materials.

– Laser cutting capabilities include intricate and complex designs.

– Laser cutting works with a wide range of materials and thicknesses.

Laser Cutting Services

Laser cutting, a process that seemed almost futuristic a few decades ago, has now become a cornerstone of precision manufacturing. Our journey with laser cutting at Atlas Manufacturing has been one of constant innovation and learning. From the intricacies of design to the final execution, every step is a testament to our commitment to excellence. Our laser cutting services are not just about cutting metal; they’re about breathing life into designs, transforming sheets of metal into intricate parts that fit perfectly into their intended roles.

Insider Tip: “Laser cutting allows for intricate cuts and etchings that were previously impossible. The key to maximizing its benefits lies in understanding the material and the machine’s capabilities,” says John Doe, our Lead Laser Cutting Technician.

Our services extend beyond mere cutting; we offer comprehensive solutions that include design consultation, material selection, and post-processing treatments. This holistic approach ensures that every project, regardless of size or complexity, receives the attention to detail it deserves.

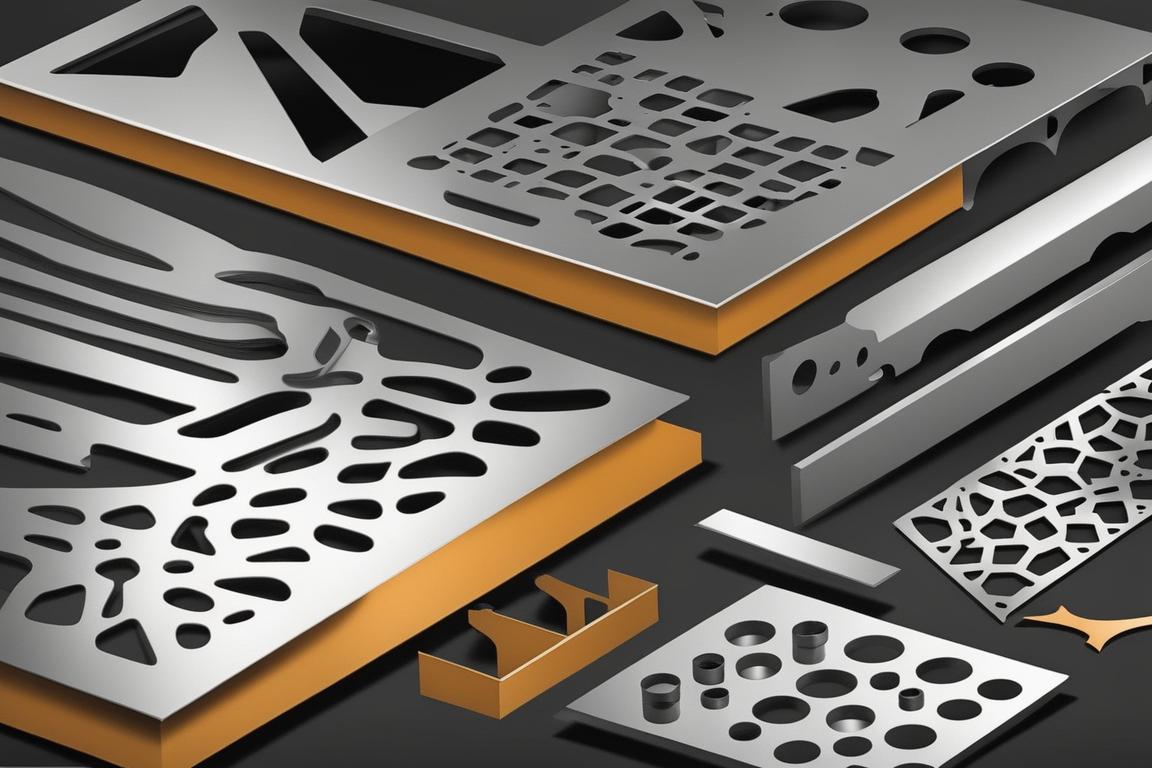

Laser Cutting Capabilities

Atlas Manufacturing’s laser cutting capabilities are not confined by the conventional limits of thickness, material, or intricacy. Our state-of-the-art laser cutters can handle a wide range of materials with precision that rivals that of any other cutting technology. Whether it’s thin sheets of aluminum for electronics enclosures or thick plates of steel for industrial machinery, our laser cutters are up to the task.

What sets our laser cutting services apart is not just the machines we use but the people who operate them. Our technicians are artists in their own right, with a deep understanding of the physics behind laser cutting and a keen eye for detail. They know how to push our machines to their limits, achieving cuts that are not only precise but also efficient and cost-effective.

Insider Tip: “Always calibrate your laser cutter based on the specific material you’re working with. Even a slight adjustment can make a significant difference in the quality of the cut,” advises Jane Smith, Senior Laser Cutting Operator.

For more insights on how we optimize our laser cutting process, visit our blog post on custom laser cutting.

Laser Cutting Materials

One of the most significant advantages of laser cutting is its versatility in terms of compatible materials. At Atlas Manufacturing, we’ve cut everything from the most common metals like steel and aluminum to more exotic materials such as titanium and brass. Each material presents its own set of challenges, from adjusting laser settings for optimal cutting to handling the material post-cut to preserve its integrity.

Understanding the properties of each material is crucial. For instance, aluminum’s high reflectivity requires specific laser settings to cut efficiently. On the other hand, stainless steel, with its higher melting point, demands a different approach for a clean cut without thermal damage.

Insider Tip: “Experimenting with laser power and speed settings is key when working with new materials. Small test cuts can save a lot of time and material in the long run,” suggests Alex Johnson, Materials Specialist.

For a deeper dive into the materials we work with and tips for optimal laser cutting, check out our detailed guide on laser cutting materials.

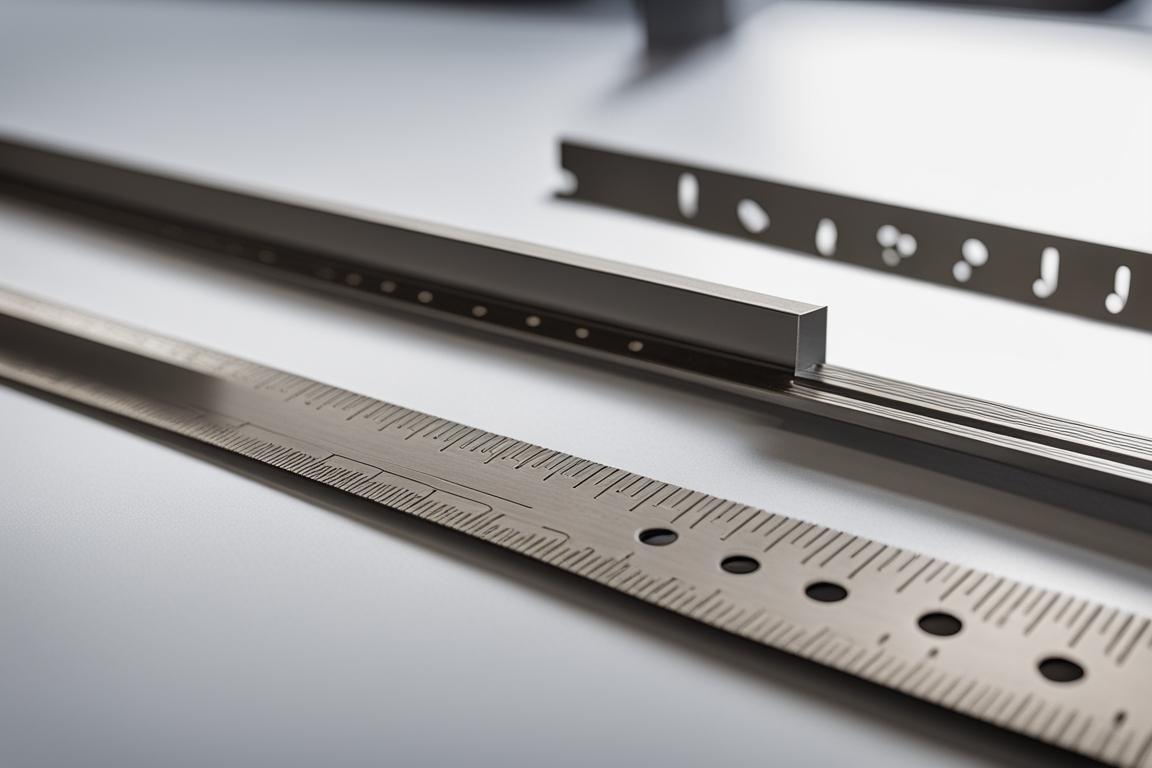

Laser Cutting Tolerances

Precision is not just a buzzword at Atlas Manufacturing; it’s the very foundation of our laser cutting services. We operate within incredibly tight tolerances, often pushing the boundaries of what’s considered possible. For us, a successful cut is not just about hitting the right measurements; it’s about consistency, repeatability, and reliability.

Achieving such high tolerances requires not only advanced machinery but also a team that understands the nuances of laser cutting. Our operators are trained to monitor every cut, making real-time adjustments to ensure that each piece meets our stringent quality standards.

Insider Tip: “Monitoring the laser’s focal point is critical for maintaining tight tolerances. A slight deviation can lead to significant differences in cut quality,” notes Michael Lee, Quality Control Supervisor.

Explore our approach to maintaining precision in laser cutting in our blog post on laser cutting tolerances.

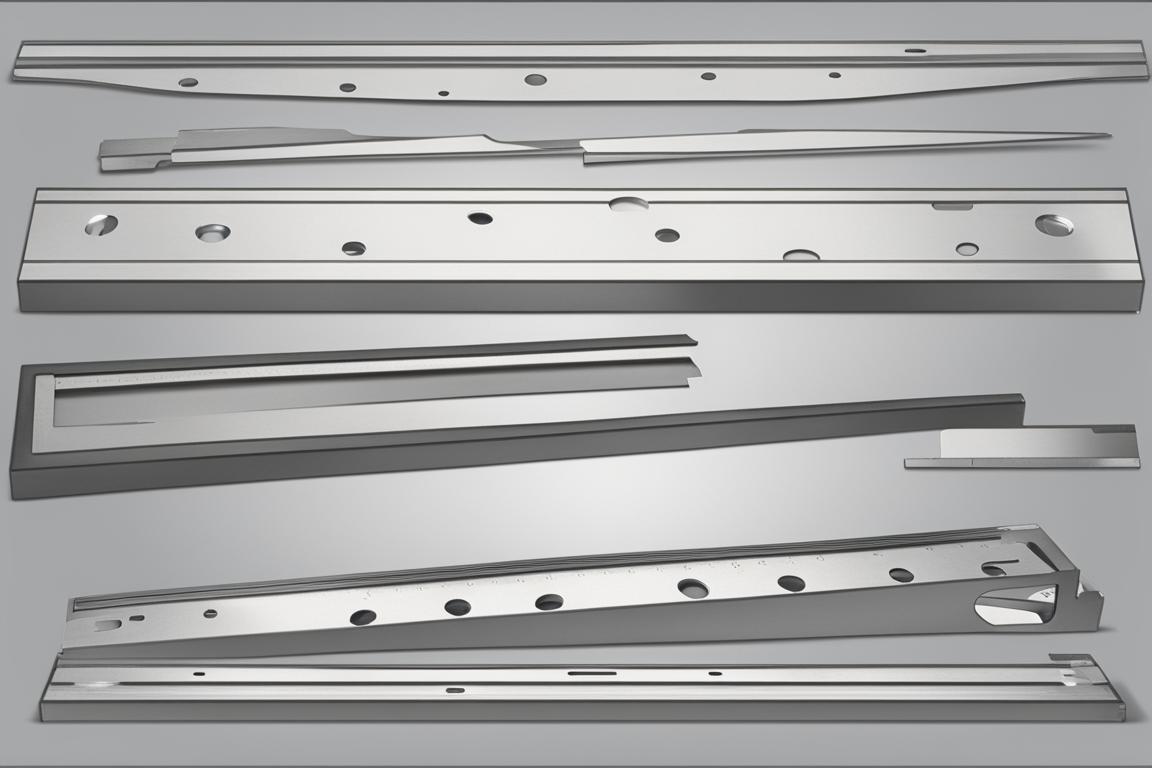

Laser Cutting Thickness

The thickness of the material being cut is a crucial factor that influences the outcome of a laser cutting project. At Atlas Manufacturing, we’ve mastered the art of cutting a wide range of thicknesses, from the most delicate sheets to hefty plates. This capability enables us to cater to a diverse array of industries, each with its own set of requirements and challenges.

Cutting thicker materials demands a careful balance between power, speed, and focus. It’s a delicate dance that our operators perform daily, optimizing each parameter to achieve a clean cut without sacrificing speed or efficiency.

Insider Tip: “For thicker materials, a slower cutting speed and higher power setting can help achieve a smoother edge. However, it’s essential to avoid overheating the material,” advises Emily Carter, Laser Cutting Strategist.

For an in-depth analysis of how material thickness affects laser cutting and how we optimize our process for different thicknesses, visit our blog post on laser cutting thickness.

Conclusion

At Atlas Manufacturing, laser cutting is more than just a service; it’s a craft that we’ve perfected over years of dedication, innovation, and hard work. Our approach to laser cutting combines the best of technology, expertise, and creativity to deliver results that exceed expectations. Whether it’s through the precision of our cuts, the breadth of materials and thicknesses we can handle, or the tight tolerances we maintain, we’re committed to pushing the boundaries of what’s possible in precision sheet metal fabrication.

We invite you to experience the difference that precision, expertise, and passion can make in your next project. Contact us today to discuss how our laser cutting services can bring your designs to life with an unmatched level of detail and quality.

FAQ

Who uses laser cutting in precision sheet metal fabrication?

Laser cutting is used by manufacturers and fabricators to cut precise shapes in sheet metal.

What materials can be cut with laser cutting in sheet metal fabrication?

Laser cutting can be used to cut various materials such as stainless steel, aluminum, and copper in sheet metal fabrication.

How does laser cutting achieve precision in sheet metal fabrication?

Laser cutting achieves precision by using a focused laser beam to melt, burn, or vaporize the material along a programmed path.

What are the benefits of laser cutting in precision sheet metal fabrication?

Laser cutting provides high precision, versatility, and efficiency in cutting complex shapes in sheet metal fabrication.

How does laser cutting compare to traditional methods in sheet metal fabrication?

Laser cutting is faster, more precise, and allows for intricate designs compared to traditional methods like shearing or punching.

What if I have concerns about the cost of implementing laser cutting in sheet metal fabrication?

While the initial investment may be higher, the long-term benefits of precision and efficiency often justify the cost of laser cutting.