Are you interested in custom laser cutting for precision sheet metal fabrication? If so, you’re in the right place. Custom laser cutting is a popular and versatile method for cutting various materials, including metals, with high precision and speed. In this article, we will explore the concept of custom laser cutting in precision sheet metal fabrication, its advantages and limitations, and how to choose a reliable and suitable custom laser cutting service. We will also provide examples of custom laser cutting services and applications, and discuss the future of custom laser cutting in the industry.

What you will learn about custom laser cutting for precision sheet metal fabrication:

- What custom laser cutting is, how it works, and what materials it can cut.

- The advantages of using custom laser cutting for precision sheet metal fabrication, including high precision, versatility, and minimal waste.

- Factors to consider when choosing a custom laser cutting service, examples of reputable services, and applications of custom laser cutting in various industries.

What is Custom Laser Cutting?

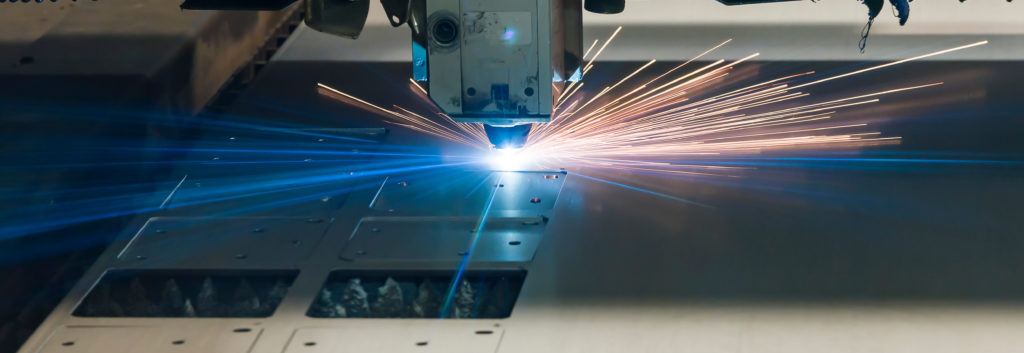

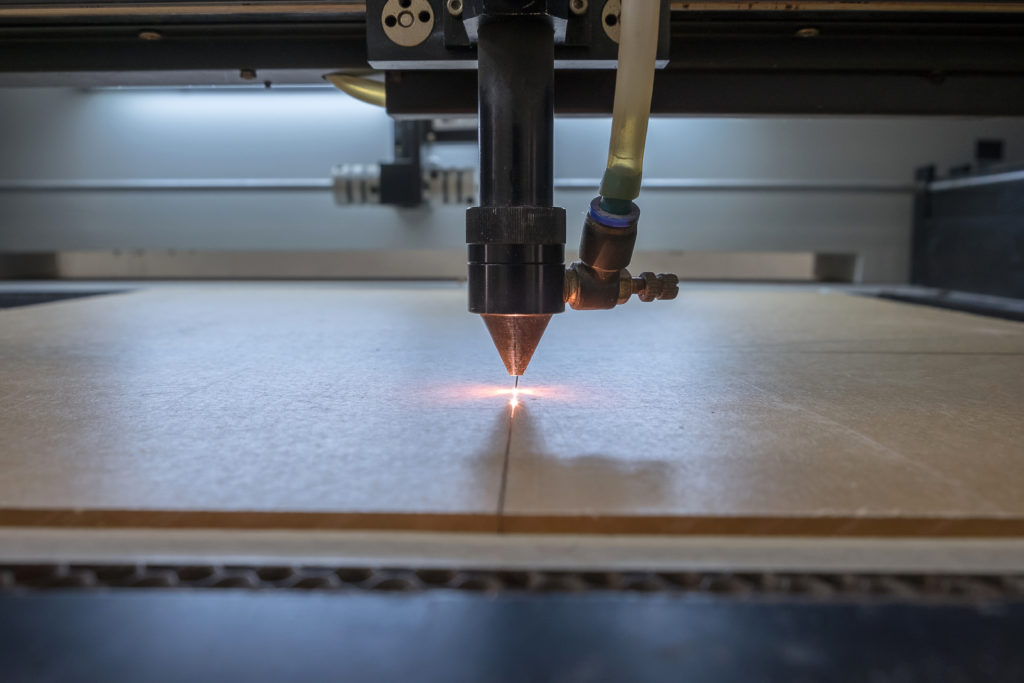

Custom laser cutting is a method of cutting materials using a thin, high-powered laser beam that melts or vaporizes the material along a precise path determined by a computer-controlled program. Unlike traditional cutting methods that use physical tools, such as saws or shears, laser cutting does not require tooling, which saves time and money and allows for more flexibility and precision in cutting complex shapes and patterns.

There are two main types of lasers used in custom laser cutting: CO2 lasers and fiber lasers. CO2 lasers are used for cutting non-metal materials, such as plastics, wood, and textiles, while fiber lasers are used for cutting metals and alloys, such as stainless steel, aluminum, and copper. The choice of laser depends on the material to be cut and the desired quality and speed of the cutting process.

Custom laser cutting can be used to cut a wide range of materials, including metals, plastics, composites, rubbers, foams, and woods. The thickness of the material that can be cut depends on the power and focus of the laser. Generally, thinner materials can be cut more precisely than thicker materials, and thicker materials may require multiple passes or a different cutting method, such as waterjet cutting or plasma cutting.

Advantages of Custom Laser Cutting for Precision Sheet Metal Fabrication

There are several benefits of using custom laser cutting for precision sheet metal fabrication, which include:

- No tooling required: Custom laser cutting does not require any physical tools, such as saws or shears, which eliminates the need for tooling costs and setup time.

- High precision and repeatability: Custom laser cutting can achieve high precision and repeatability, which ensures consistent quality and tight tolerances.

- Versatility in cutting complex shapes and patterns: Custom laser cutting can cut intricate shapes, patterns, and designs with high accuracy and speed, which allows for more design flexibility and creativity.

- Minimal material waste and distortion: Custom laser cutting minimizes material waste and distortion, which maximizes material utilization and reduces post-processing.

Custom laser cutting can be used in precision sheet metal fabrication for several applications, such as:

- Creating prototypes, samples, or low-volume production runs of custom parts for testing or validation.

- Cutting intricate features, such as notches, holes, slots, or logos, on thin or thick sheets of metal.

- Scaling up production of custom parts by leveraging the speed and accuracy of laser cutting.

Factors to Consider When Choosing a Custom Laser Cutting Service

When choosing a custom laser cutting service, there are several key factors to consider that can affect the quality, cost, and lead time of the service, such as:

- Material selection and compatibility with laser cutting: Some materials may not be suitable for laser cutting, or may require special considerations, such as thickness and composition. It is important to choose a service that has expertise in the material(s) you need to cut.

- Design requirements and file formats: The quality and efficiency of the laser cutting process depend on the accuracy and compatibility of the design files provided. It is important to choose a service that offers design guidelines and support, and can work with various file formats, such as DXF, DWG, or AI.

- Machine capabilities and maintenance: The speed, power, and reliability of the laser cutting service depend on the quality and maintenance of the laser cutting machines used. It is important to choose a service that has modern and well-maintained machines, and can handle various thicknesses and sizes of materials.

- Post-processing options and costs: The final quality and appearance of the custom parts may require additional post-processing, such as deburring, polishing, coating, or assembly. It is important to choose a service that offers various post-processing options and costs, and can provide samples or references of their work.

To choose a reliable and suitable custom laser cutting service, you can follow these tips:

- Check the service’s expertise, reputation, and customer reviews: Look for a service that has experience and positive feedback from customers in your industry or niche.

- Request samples, quotes, and lead times for different materials and designs: Test the service’s quality, responsiveness, and pricing by requesting samples or quotes for different materials and designs.

- Communicate clearly and promptly with the service’s staff: Ensure proper specifications and expectations by communicating clearly and promptly with the service’s staff, and asking questions or providing feedback as needed.

| Custom Laser Cutting Service | Materials | Thickness | Machine Capabilities | Post-processing Options |

|---|---|---|---|---|

| SendCutSend | Aluminum, steel, brass, plastics, titanium, and more | Up to 3/8 inch | CO2 and fiber lasers, automated quality control, and real-time pricing | Deburring, powder coating, anodizing, and more |

| Xometry | Metals, plastics, and other materials | Up to 4 inches | CO2 and fiber lasers, instant quoting, and free shipping | Deburring, bending, threading, and more |

| Pololu | Plastics, woods, steel, paper, cloth, and more | Up to 1/4 inch | CO2 laser, custom part creation, and engraving options | None mentioned |

Examples of Custom Laser Cutting Services for Precision Sheet Metal Fabrication

There are several custom laser cutting services that cater to the precision sheet metal fabrication niche, each with its own features, strengths, and limitations. Here are some examples of reputable and specialized custom laser cutting services:

- SendCutSend: SendCutSend is an online CNC and laser cutting service, specializing in aluminum, steel, brass, plastics, titanium, and more. They offer fast turnaround and free shipping, and provide online guidelines, material charts, and support for perfect results.

- Xometry: Xometry provides an online laser cutting service for various materials, offering instant quotes and free shipping in the US. They use fiber and CO2 lasers to cut through materials up to 4 inches thick, and suggest waterjet and plasma cutting for thicker materials.

- Pololu: Pololu offers a custom laser cutting service for various sheet materials, with fast and affordable creation of custom parts, smooth curves, and engraving options. They can work with plastics, woods, steel, paper, cloth, and more, but cannot cut thick metals, PVC, polycarbonate, or carbon fiber. They offer pricing starting at $25 with no set-up fees, and discounts for larger orders. Expedited services and same-day delivery are available for local customers.

Applications of Custom Laser Cutting in Precision Sheet Metal Fabrication

Custom laser cutting can be used in various industries that require precision sheet metal fabrication, such as:

- Aerospace and aviation industries: Custom laser cutting can be used to create lightweight and complex parts for aircraft and spacecraft, such as brackets, panels, and frames.

- Medical and healthcare industries: Custom laser cutting can be used to create medical devices and instruments, such as surgical tools, implants, and prosthetics.

- Automotive and transportation industries: Custom laser cutting can be used to create parts for cars, trains, and ships, such as exhaust systems, chassis, and panels.

- Electronics and technology industries: Custom laser cutting can be used to create parts for computers, smartphones, and other devices, such as cases, heat sinks, and connectors.

Custom laser cutting provides several benefits for these industries, such as high precision, speed, and flexibility, which can improve the quality and efficiency of the fabrication process.

Limitations and Challenges of Custom Laser Cutting

Although custom laser cutting has many advantages, it also has some limitations and challenges that need to be considered, such as:

- Limited thickness and size of materials that can be cut: Custom laser cutting is most effective for cutting thin to medium thickness materials, and may not be suitable for cutting very thick or large materials.

- Cost and complexity of laser cutting machines: Custom laser cutting machines can be expensive and require regular maintenance and calibration, which can affect the cost and lead time of the service.

- Safety concerns and regulatory compliance: Custom laser cutting involves the use of high-powered lasers that can pose health and safety risks if not handled properly. It is important to follow safety protocols and regulatory compliance requirements to ensure a safe and legal operation.

To overcome these limitations and challenges, it is important to consider alternative cutting methods, such as waterjet cutting or plasma cutting, for thicker or larger materials, and to invest in proper training, equipment, and safety measures for laser cutting operations.

Real-Life Personal Story: Overcoming Design Challenges with Custom Laser Cutting

As a mechanical engineer at a small startup, I was tasked with designing a custom enclosure for our latest product. The enclosure needed to be made of sheet metal, with intricate cutouts and bends to fit all the components and wires. I quickly realized that using traditional cutting methods, such as sawing or punching, would be time-consuming and unreliable, given the complexity of the design.

That’s when I decided to explore custom laser cutting services for precision sheet metal fabrication. After some research and consultations with various providers, I found a reliable and affordable service that specialized in laser cutting of thin sheets of aluminum. I provided them with my CAD files and material specifications, and they sent me a quote and a proof of concept within a day.

I was impressed with the quality and precision of the laser cuts, as well as the smooth edges and minimal distortion of the metal. With the custom laser-cut parts, I was able to assemble the enclosure within hours, instead of days, and the final product fit perfectly and looked professional.

Not only did custom laser cutting save me time and money, but it also allowed me to experiment with different design iterations and modifications, without worrying about tooling or setup costs. I was able to incorporate new features and improvements quickly, which helped us to meet our deadlines and exceed our customers’ expectations.

From that experience, I learned that custom laser cutting is not only a cutting-edge technology but also a practical and versatile solution for precision sheet metal fabrication. Whether you need to make prototypes, small runs, or large batches of custom parts, laser cutting can help you achieve high quality, accuracy, and efficiency, while minimizing waste and errors.

Future of Custom Laser Cutting in Precision Sheet Metal Fabrication

The future of custom laser cutting in precision sheet metal fabrication looks promising, as new materials, designs, and applications emerge, and as the industry continues to innovate and improve. Some of the potential trends and developments in custom laser cutting include:

- Integration with other fabrication methods, such as 3D printing or CNC milling, to create more complex and customized parts.

- Expansion to new industries and niches, such as renewable energy, construction, or consumer goods, that require precision sheet metal fabrication.

- Advancements in machine learning and artificial intelligence that can optimize the cutting process and reduce errors and waste.

- Adoption of sustainable and eco-friendly practices and materials that can reduce the environmental impact of precision sheet metal fabrication.

As the industry evolves, it is important for professionals and stakeholders to stay informed and engaged in the field, and to share their insights and feedback with others. Custom laser cutting has the potential to revolutionize precision sheet metal fabrication and to create new opportunities and solutions for various industries and applications.