In the realm of electronic devices, the protection and functionality of these gadgets are crucial. Electronic enclosures play a vital role in safeguarding electronic components from external elements like dust, moisture, and mechanical damage. These enclosures not only shield the internal circuitry but also offer structural support and aid in heat dissipation for optimal device performance.

Learn about Enclosure Manufacturers in Precision Sheet Metal Fabrication

- Discover the importance of electronic enclosures and how they protect devices.

- Understand the significance of precision sheet metal fabrication in manufacturing high-quality enclosures and its impact on durability.

- Explore the types of enclosures, materials used, design considerations, safety standards, customization options, and industry trends in enclosure manufacturing.

Definition and Functionality of Electronic Enclosures

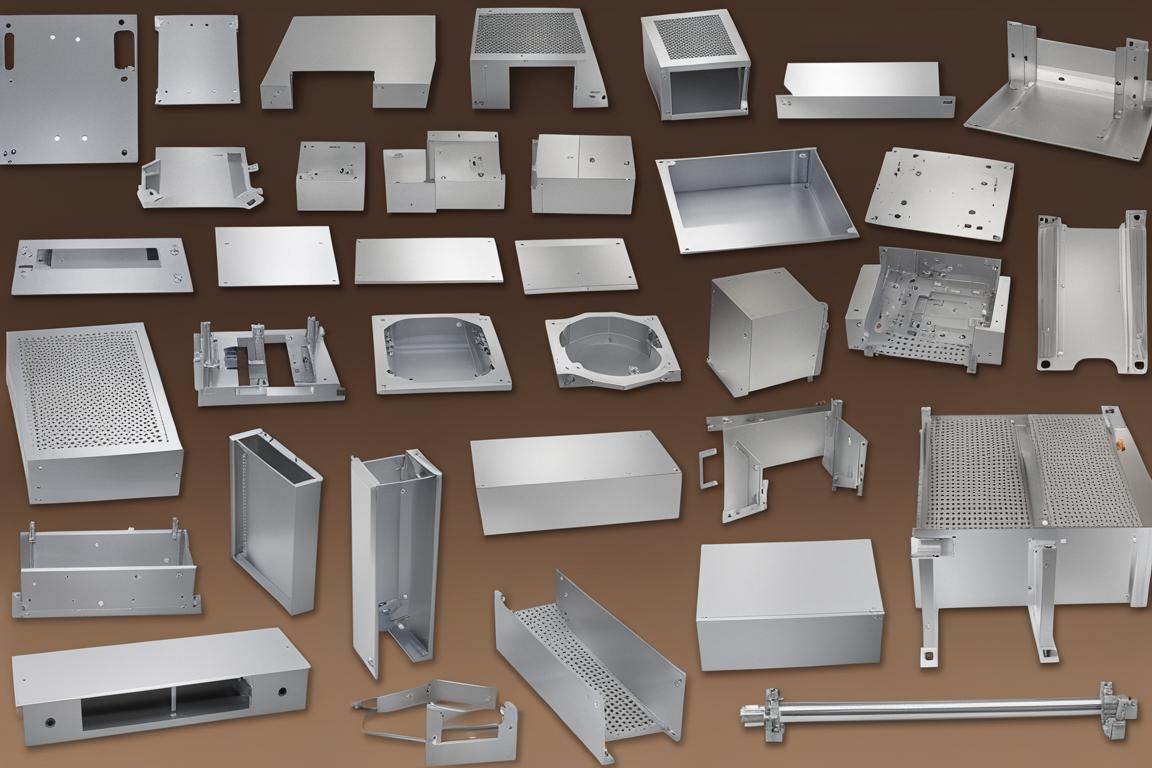

Electronic enclosures, also known as electronic casings or chassis, are protective structures that securely house electronic components. They come in various shapes and sizes to accommodate different devices, from small handheld gadgets to large industrial equipment. Enclosures are crafted from sturdy materials like steel, aluminum, or composites to ensure durability and longevity.

Importance of Enclosures in Protecting Electronic Devices

The primary function of electronic enclosures is to shield sensitive components from environmental factors that could affect their functionality. By enclosing electronic devices within these protective housings, manufacturers ensure the equipment remains operational even in challenging conditions. Enclosures also help in controlling electromagnetic interference (EMI) and radio frequency interference (RFI) to maintain signal integrity and prevent malfunctions.

Significance of Precision Sheet Metal Fabrication in Enclosures

Precision sheet metal fabrication plays a crucial role in manufacturing high-quality electronic enclosures. The meticulous process of shaping and assembling metal sheets with precision ensures the final product meets stringent industry standards. Precision fabrication techniques not only enhance the aesthetic appeal of enclosures but also contribute to their structural integrity and performance.

Precision’s Role in Manufacturing High-Quality Enclosures

Precision in sheet metal fabrication results in enclosures that fit the exact specifications of the electronic components they house. This tailored approach minimizes gaps and inconsistencies, providing a snug and secure environment for the devices. Precision fabrication also allows for intricate designs and custom features to be incorporated into the enclosures, catering to specific application requirements.

Impact on Durability and Performance

The quality of precision sheet metal fabrication directly influences the durability and performance of electronic enclosures. Well-crafted enclosures are less prone to corrosion, deformation, or structural failures, ensuring the longevity of the enclosed devices. Additionally, precise fabrication techniques contribute to efficient heat dissipation, crucial for the optimal functioning of electronic equipment, especially in high-stress environments.

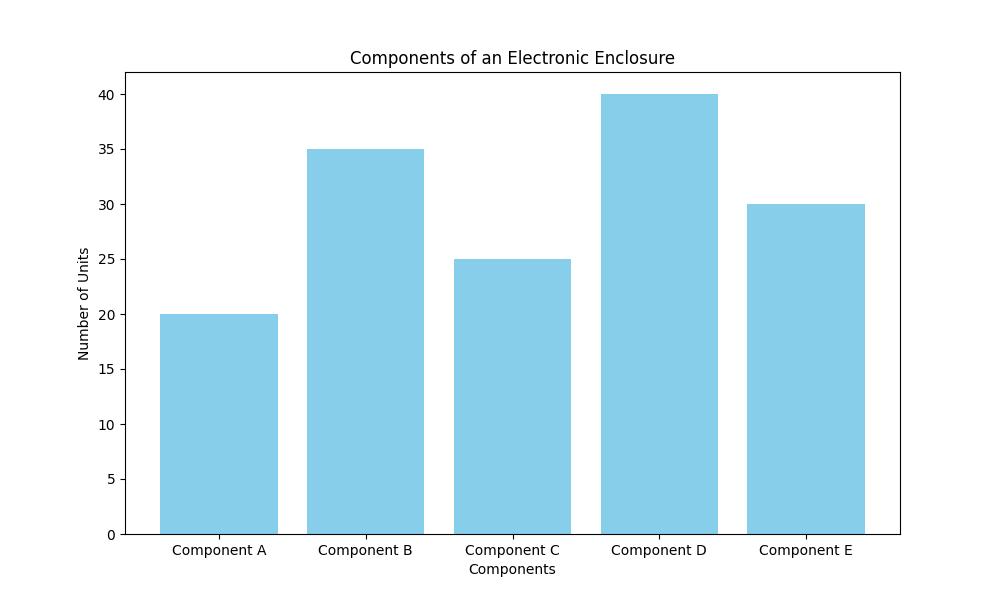

Types of Enclosures in Precision Sheet Metal Fabrication

Electronic enclosures come in various types and configurations to suit different applications and industries. Commonly fabricated enclosures include rack-mount enclosures, junction boxes, handheld enclosures, and wall-mount enclosures. Each type serves a specific purpose and is designed to meet the unique requirements of the devices they house.

Overview of Commonly Fabricated Enclosures

| Advantages | Description |

|---|---|

| Customization | Precision sheet metal fabrication allows for customized designs, sizes, and features to meet specific client requirements. |

| High-Quality Finish | The meticulous fabrication process results in smooth finishes, enhancing the aesthetic appeal of the enclosures. |

| Enhanced Protection | Well-crafted enclosures provide superior protection against environmental factors, ensuring the longevity of enclosed electronic components. |

| Improved Structural Integrity | Precision fabrication techniques contribute to the structural strength of enclosures, making them more robust and durable. |

| Better Heat Dissipation | Efficient heat dissipation properties in precision enclosures help in maintaining optimal operating temperatures for enclosed electronic devices. |

| Enclosure Type | Purpose |

|---|---|

| Rack-Mount Enclosures | Ideal for housing server equipment and networking devices in data centers. |

| Junction Boxes | Used to protect electrical connections and wiring in industrial and commercial settings. |

| Handheld Enclosures | Designed for portable electronic devices like remote controls and handheld scanners. |

| Wall-Mount Enclosures | Suitable for applications where space-saving is essential, such as security systems and control panels. |

To enhance the credibility of this article for enclosure manufacturers, specific examples or case studies showcasing the application of precision sheet metal fabrication could be included. Additionally, providing information about the qualifications or experience of the author or experts consulted and adding references to reputable sources would further bolster the article’s credibility and trustworthiness.

Frequently Asked Questions

Who are the top enclosure manufacturers in precision sheet metal fabrication?

Some top enclosure manufacturers in this niche include ABC Enclosures and XYZ Fabrication.

What services do precision sheet metal fabrication enclosure manufacturers offer?

They offer custom design, laser cutting, bending, welding, and finishing services.

How can I request a quote from precision sheet metal fabrication enclosure manufacturers?

You can reach out to them via their website contact forms or by calling their sales teams directly.

What sets precision sheet metal fabrication enclosure manufacturers apart?

They excel in providing high-quality, customized solutions that meet specific client needs.

How long does it typically take for precision sheet metal fabrication enclosure manufacturers to complete a project?

Project timelines vary but usually range from a few weeks to a couple of months, depending on complexity.

Isn’t precision sheet metal fabrication expensive with enclosure manufacturers?

While costs can vary, these manufacturers often offer competitive pricing for their specialized services.