Learn about Custom Sheet Metal Boxes

- Significance of custom sheet metal boxes in various industries.

- Benefits, design process, material selection, fabrication techniques, and customization options for custom sheet metal boxes.

- How to choose the right fabrication partner and maintain sheet metal boxes for longevity.

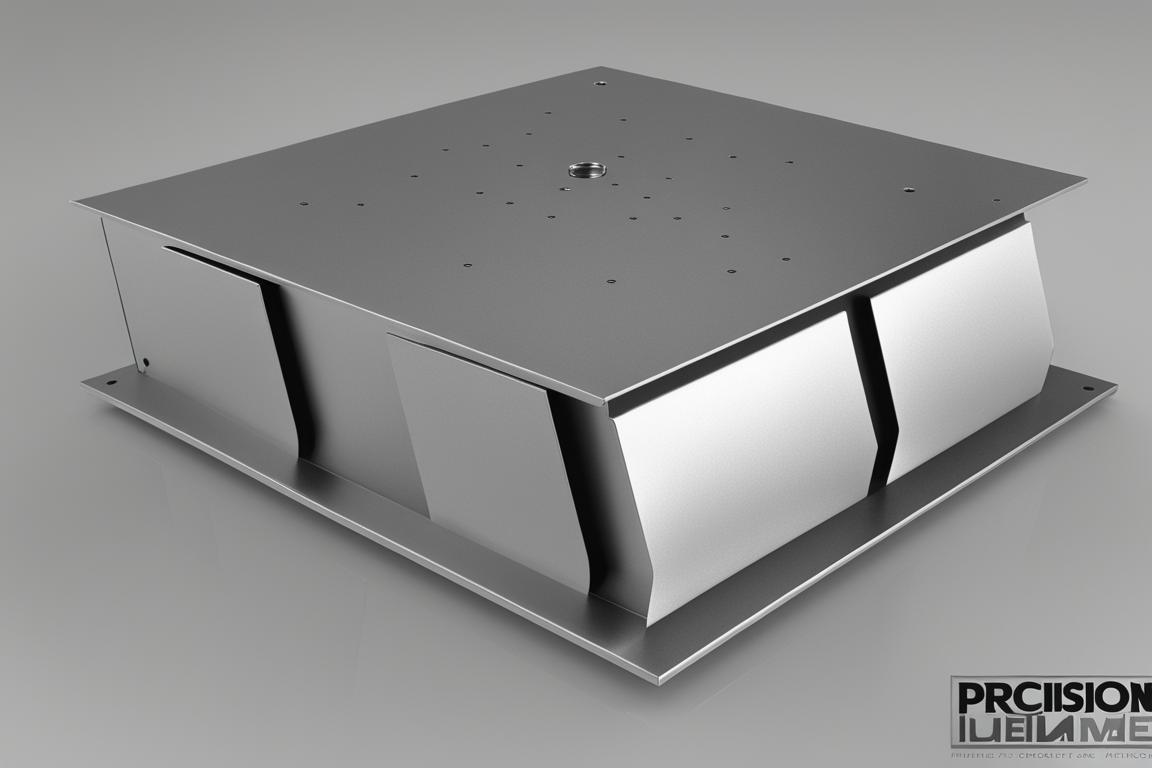

Are you wondering about the intricacies of custom sheet metal boxes? In various industries, the need for custom sheet metal boxes has been on the rise due to their versatility and precision in meeting specific requirements. These boxes are tailor-made solutions crafted from sheet metal to suit unique dimensions, shapes, and functionalities. Unlike standard off-the-shelf options, custom sheet metal boxes offer a bespoke approach to storage, transportation, or protection needs, making them indispensable in sectors such as electronics, aerospace, and automotive.

Benefits of Custom Sheet Metal Boxes

Custom sheet metal boxes provide a myriad of benefits that set them apart from mass-produced alternatives. One of the primary advantages is precision. By customizing the dimensions and features of the box, users can optimize space utilization and ensure a perfect fit for their intended purpose. Additionally, the durability of sheet metal ensures long-term structural integrity, offering robust protection for valuable equipment or components. Moreover, the aesthetic appeal of custom boxes can be enhanced through various finishing options, adding a professional touch to the final product.

Design and Engineering Process

The design and engineering process for custom sheet metal boxes involves a meticulous approach to ensure optimal functionality and quality. CAD design plays a crucial role in creating detailed blueprints that guide the fabrication process. Prototyping is often employed to test the design’s feasibility and make necessary adjustments before full-scale production begins. This iterative process allows for fine-tuning of the box’s specifications to meet the client’s exact requirements.

CAD Design in Custom Sheet Metal Boxes

CAD design software enables engineers to create precise 3D models of custom sheet metal boxes, facilitating accurate measurements and visualizations of the final product. By leveraging CAD technology, designers can anticipate challenges and make necessary modifications early in the design phase, streamlining the production process.

Material Selection for Custom Sheet Metal Boxes

The choice of sheet metal materials is critical in the fabrication of custom boxes, as different metals offer unique properties that impact the box’s performance and durability. Commonly used materials include aluminum, stainless steel, and carbon steel, each with distinct characteristics suited for specific applications. Aluminum, known for its lightness and corrosion resistance, is often preferred for its versatility, while stainless steel’s strength and aesthetic appeal make it ideal for high-end applications.

| Fabrication Technique | Description |

|---|---|

| Cutting | Shaping metal sheets according to design specifications using laser cutting or shearing methods |

| Bending | Forming the structural components of the box through bending techniques |

| Welding | Joining individual components together to create a sturdy structure using TIG or MIG welding |

| Finishing | Enhancing the appearance and durability of the box through treatments like powder coating or anodizing |

Fabrication Techniques for Custom Sheet Metal Boxes

Fabricating custom sheet metal boxes involves a series of intricate techniques to transform raw materials into functional and aesthetically pleasing products. Cutting processes such as laser cutting or shearing are used to shape the metal sheets according to the design specifications. Bending techniques create the box’s structural components, while welding ensures seamless joints for a sturdy construction. Finally, finishing treatments such as powder coating or anodizing enhance the box’s appearance and durability.

Welding in Custom Sheet Metal Boxes

Welding is a critical process in custom sheet metal box fabrication, as it enables the assembly of individual components into a cohesive structure. TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are commonly used techniques to create strong and durable joints that withstand various environmental conditions.

Precision and Quality Control Measures

Maintaining precision and adhering to quality control measures are paramount in producing custom sheet metal boxes that meet stringent standards. Quality checks at each stage of the fabrication process help identify and rectify any deviations from the design specifications. By implementing rigorous quality control protocols, manufacturers ensure consistency and reliability in the final products, earning the trust of clients for delivering exceptional craftsmanship.

Customization Options for Sheet Metal Boxes

Clients have a wide array of customization options available when ordering sheet metal boxes to tailor the product to their exact needs. From choosing the box’s dimensions and shape to selecting specific colors and finishes, customization allows for creating unique solutions that align with individual preferences and branding requirements. Additionally, features like custom logos or labels can be incorporated to enhance the box’s branding and identification.

Case Studies of Custom Sheet Metal Box Projects

To exemplify the practical applications of custom sheet metal boxes, let’s explore a few case studies that showcase their versatility and functionality in real-world scenarios:

- Electronics Industry: Custom sheet metal boxes designed for housing delicate electronic components, ensuring protection and efficient organization.

- Medical Equipment: Precision-crafted sheet metal boxes used to store and transport critical medical devices, meeting strict hygiene and safety standards.

- Automotive Sector: Customized sheet metal boxes for automotive parts storage, optimizing space utilization and facilitating inventory management.

Current Industry Trends in Custom Sheet Metal Box Fabrication

The landscape of custom sheet metal box fabrication is constantly evolving, driven by technological advancements and market demands. Digitalization of design processes through CAD software has expedited production timelines and enhanced design accuracy. Sustainable practices such as recycling scrap metal and optimizing material usage are gaining traction, reflecting the industry’s commitment to environmental stewardship. Additionally, automation in manufacturing processes is revolutionizing efficiency and quality control measures, paving the way for enhanced productivity and cost-effectiveness.

Choosing the Right Fabrication Partner

Selecting the right fabrication partner is crucial for the success of custom sheet metal box projects. When evaluating potential partners, consider their expertise in sheet metal fabrication, capabilities in handling complex designs, and customer feedback on past projects. A reputable partner with a track record of delivering quality products on time and within budget can streamline the production process and ensure the seamless realization of your custom box requirements.

Maintenance and Care Guidelines for Sheet Metal Boxes

To prolong the lifespan and functionality of custom sheet metal boxes, it is essential to adhere to maintenance and care guidelines. Regular cleaning and inspection help prevent corrosion and damage, ensuring the box remains in optimal condition. Avoiding exposure to harsh chemicals and extreme temperatures can preserve the box’s integrity, while periodic lubrication of hinges and joints maintains smooth operation. By following these simple maintenance practices, users can maximize the longevity of their custom sheet metal boxes.

Future Prospects in Custom Sheet Metal Box Fabrication

As technology continues to advance and market demands evolve, the future of custom sheet metal box fabrication holds promising opportunities for innovation and growth. Emerging trends such as 3D printing of metal components and smart integration for IoT (Internet of Things) applications are reshaping the industry landscape. Furthermore, advancements in sustainable materials and energy-efficient processes are driving sustainability initiatives in sheet metal fabrication, aligning with global efforts towards eco-friendly manufacturing practices.

FAQs

Who can benefit from custom sheet metal boxes?

Businesses in need of precise and durable storage solutions.

What makes custom sheet metal boxes unique?

They are tailored to specific dimensions and designs.

How are custom sheet metal boxes fabricated?

They are crafted using precision sheet metal fabrication techniques.

Who can I contact for custom sheet metal box orders?

You can reach out to experienced sheet metal fabrication companies.

What if I need a custom sheet metal box quickly?

Some fabrication companies offer expedited services for urgent orders.

How durable are custom sheet metal boxes?

Custom sheet metal boxes are incredibly sturdy and long-lasting.