Custom sheet metal fabrication is a vital and versatile process in precision manufacturing. It involves creating bespoke metal components and products tailored to specific project requirements. This article delves into the intricacies of custom sheet metal fabrication, exploring its significance, customer needs, design and engineering, material selection, fabrication processes, quality control, and future trends.

What You’ll Learn About Custom Sheet Metal Fabrication

By reading this article, you’ll learn:

– The importance and advantages of custom sheet metal fabrication

– How to understand and meet customer needs for custom sheet metal

– The processes, materials, quality control, and future trends in custom sheet metal fabrication

What is Custom Sheet Metal Fabrication and Its Significance?

Custom sheet metal fabrication refers to transforming raw metal sheets into custom-designed products and components. Its significance lies in its ability to cater to unique specifications, ensuring that the end products perfectly fit the intended application.

Meeting Customer Needs

Understanding the customer’s needs is paramount in custom sheet metal fabrication. It begins with an initial consultation to grasp the project’s intricacies and requirements.

Initial Consultation and Project Requirements

Detailed discussions with the client to gain a comprehensive understanding of their specific needs, including functional requirements, design preferences, and desired performance characteristics.

Material Choice, Dimensions, and Tolerances

Choosing the appropriate material, determining dimensions, and defining tolerance levels are crucial factors contributing significantly to the success of the custom sheet metal fabrication project.

Importance of Clear Communication

Clear and consistent communication between the client and the fabrication team is vital throughout the project to ensure the fabricated components align with the client’s expectations and functional requirements.

Design and Engineering for Custom Sheet Metal Fabrication

The design and engineering phase of custom sheet metal fabrication is crucial as it sets the foundation for the entire manufacturing process.

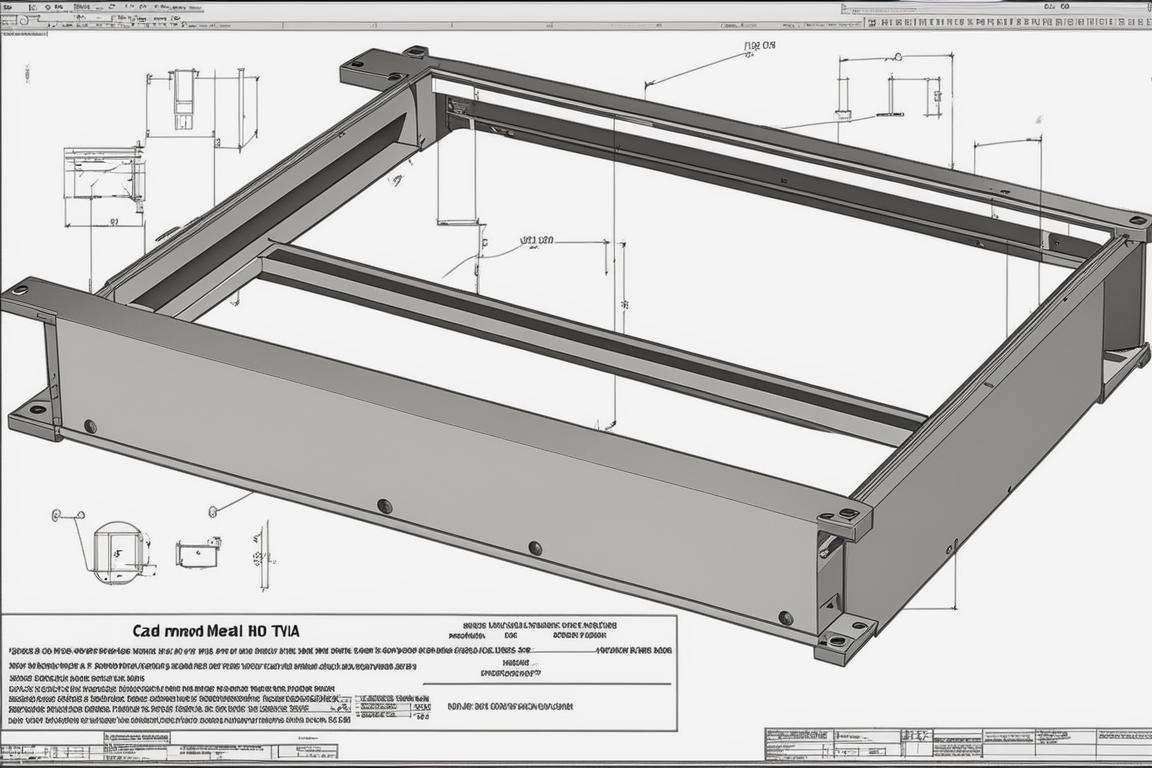

CAD Drawings and Modeling

Utilizing computer-aided design (CAD) software to create detailed drawings and 3D models of the custom sheet metal components allows for precise visualization and validation of the design before the fabrication process begins.

Customization and Tailored Solutions

Leveraging advanced design techniques to cater to unique geometric and functional requirements.

Ensuring Compliance with Specifications

Ensuring compliance with industry specifications and standards guarantees that the fabricated components meet regulatory and quality requirements.

Material Selection

Material selection is a critical aspect of custom sheet metal fabrication, influencing the performance, durability, and aesthetics of the final product.

Types of Materials Used

Custom sheet metal fabrication encompasses a wide array of materials, including stainless steel, aluminum, and copper, each offering distinct properties and benefits for different application needs.

Factors Influencing Material Selection

Mechanical properties, corrosion resistance, and cost play a pivotal role in determining the most suitable material for a custom sheet metal fabrication project.

Material Properties and Applications

Understanding the unique properties of each material and their applications is essential in making informed decisions during the material selection process.

| Cutting and Forming Processes | Description |

|---|---|

| Laser Cutting and Precision Cutting Techniques | Utilizing laser cutting and precision cutting techniques enable intricate and precise shaping of the metal sheets, allowing for the creation of complex geometries with exceptional accuracy. |

| Bending, Folding, and Shaping Processes | Employing bending, folding, and shaping processes to form the metal sheets into the required configurations ensures that they align with the design specifications. |

| Welding and Joining Methods | Utilizing welding and joining methods to assemble multiple components, creating a cohesive structure that fulfills the functional requirements of the custom sheet metal products. |

Cutting and Forming Processes

The cutting and forming processes are where the raw metal sheets are transformed into the desired shapes and structures.

Laser Cutting and Precision Cutting Techniques

Utilizing laser cutting and precision cutting techniques enable intricate and precise shaping of the metal sheets, allowing for the creation of complex geometries with exceptional accuracy.

Bending, Folding, and Shaping Processes

Employing bending, folding, and shaping processes to form the metal sheets into the required configurations ensures that they align with the design specifications.

Welding and Joining Methods

Utilizing welding and joining methods to assemble multiple components, creating a cohesive structure that fulfills the functional requirements of the custom sheet metal products.

Finishing and Surface Treatment

The finishing and surface treatment phase adds the final touches to the fabricated components, enhancing their aesthetics and functionality.

Importance of Surface Finish

The surface finish not only contributes to the visual appeal of the custom sheet metal products but also influences their corrosion resistance and durability.

Powder Coating, Anodizing, and Plating Options

Popular surface treatment options such as powder coating, anodizing, and plating offer protective and decorative enhancements to the fabricated metal components.

Enhancing Aesthetics and Functionality

The finishing and surface treatment processes are geared towards enhancing both the aesthetics and functionality of the custom sheet metal products, ensuring they meet the desired standards.

Quality Control and Inspection

Maintaining stringent quality control measures is essential to ensure the reliability and performance of custom sheet metal products.

Adhering to Industry Standards

Adhering to industry standards and quality benchmarks is fundamental to delivering custom sheet metal products that meet or exceed customer expectations.

Inspection Processes at Key Stages

Conducting inspection processes at key stages of fabrication to identify and rectify any deviations from the specified requirements, ensuring that the final products align with the client’s needs.

Ensuring Product Quality and Consistency

By upholding rigorous quality control practices, custom sheet metal fabricators ensure that the fabricated components exhibit consistency and adhere to the highest quality standards.

Customization and Versatility

Custom sheet metal fabrication offers a high degree of customization and versatility, making it suitable for diverse applications.

Diverse Applications

Custom sheet metal fabrication finds application in a wide range of industries, including aerospace, automotive, electronics, and architecture.

Tailoring Products to Industry and Project Needs

The versatility of custom sheet metal fabrication allows for tailoring products to meet the specific needs and requirements of different industries and project scopes.

Complex Assemblies and Specialized Fabrication

The capability to handle complex assemblies and specialized fabrication requirements positions custom sheet metal fabrication as a solution for intricate and demanding projects.

Case Studies and Success Stories

Examining real-life case studies and success stories provides valuable insights into the capabilities and accomplishments of custom sheet metal fabrication.

Real-life Examples of Custom Sheet Metal Projects

Case studies showcase the application of custom sheet metal fabrication in solving unique engineering and design challenges across various industries.

Demonstrating Expertise and Capabilities

Through successful case studies, custom sheet metal fabricators demonstrate their expertise and capabilities in delivering innovative solutions to complex manufacturing requirements.

Meeting Varied Customer Requirements

Success stories highlight the ability of custom sheet metal fabrication to meet varied customer requirements, from prototyping to large-scale production.

Future Trends and Innovations

The future of custom sheet metal fabrication is shaped by emerging technologies and innovative trends that are revolutionizing the industry.

Emerging Technologies

Advancements in automation, artificial intelligence, and digital manufacturing are reshaping the landscape of custom sheet metal fabrication, offering new possibilities and efficiencies.

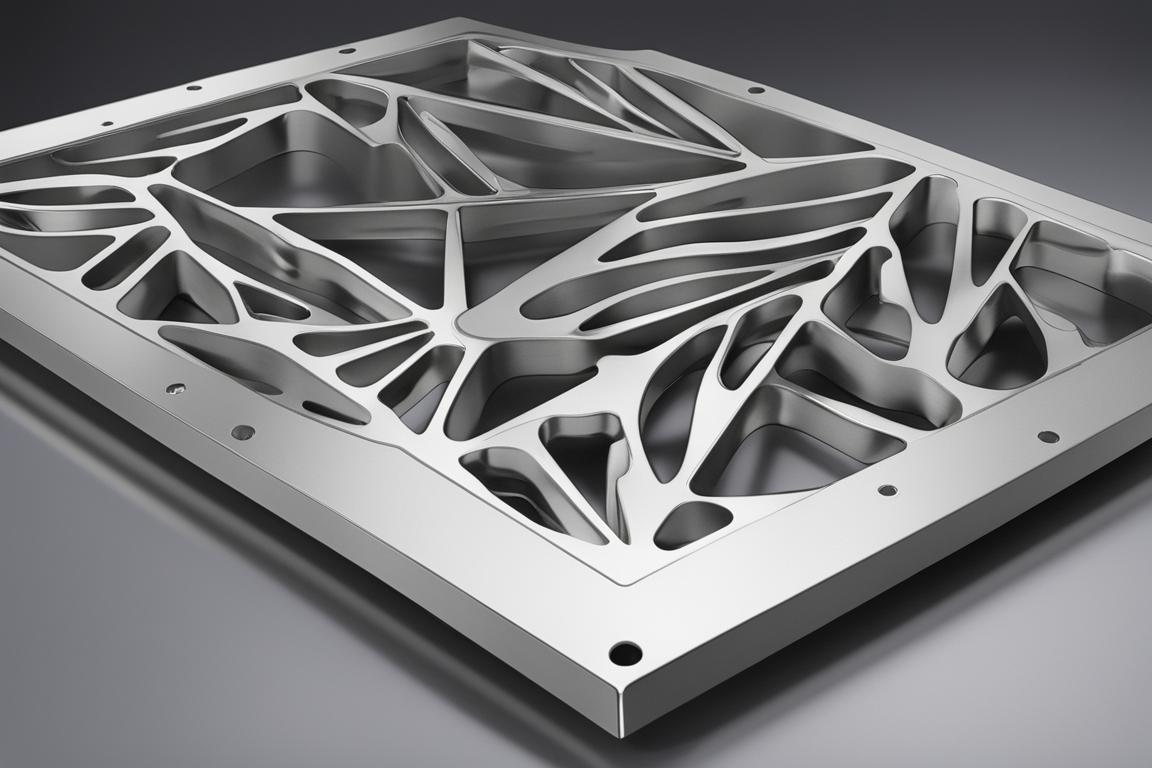

Impact of 3D Metal Printing and Automation

The integration of 3D metal printing and automation is poised to drive significant advancements in custom sheet metal fabrication, enabling rapid prototyping and intricate design realization.

Advancements Shaping the Industry’s Future

From sustainable practices to advanced material technologies, the industry’s future is marked by continuous advancements that enhance efficiency, sustainability, and product innovation.

Choosing the Right Fabrication Partner

Selecting a reliable and capable fabrication partner is instrumental in the success of custom sheet metal projects.

Criteria for Selecting a Reliable Custom Sheet Metal Fabricator

Industry experience, technological capabilities, and a track record of delivering quality products are essential criteria when choosing a fabrication partner.

Considering Expertise and Equipment Capabilities

The expertise of the fabrication team and the capabilities of their equipment play a significant role in ensuring the successful execution of custom sheet metal projects.

Importance of Customer Satisfaction and Testimonials

Customer satisfaction and testimonials serve as indicators of a fabrication partner’s commitment to quality, reliability, and customer-centric service.

Tips for Cost-Effective Fabrication

Achieving cost-effective custom sheet metal fabrication involves optimizing processes and balancing cost efficiency with quality.

Optimizing Fabrication Processes

Streamlining fabrication processes, minimizing material waste, and optimizing production workflows contribute to cost-effective custom sheet metal fabrication.

Balancing Cost Efficiency and Quality

Balancing cost efficiency with quality is a delicate yet crucial aspect of custom sheet metal fabrication, ensuring that the end products meet performance standards while staying within budget constraints.

Maximizing Value in Custom Sheet Metal Projects

Leveraging the expertise of the fabrication partner to identify cost-saving opportunities without compromising on the quality and integrity of the custom sheet metal products.

Environmental Considerations

Addressing environmental considerations is becoming increasingly important in the custom sheet metal fabrication industry.

Sustainable Materials and Practices

The adoption of sustainable materials and environmentally friendly practices in custom sheet metal fabrication contributes to reducing the industry’s ecological footprint.

Minimizing Ecological Footprint

Efforts to minimize the ecological footprint through responsible waste management, energy-efficient processes, and eco-friendly materials are pivotal in promoting sustainable fabrication practices.

Eco-Friendly Approaches

Embracing eco-friendly approaches, such as recycling and utilizing renewable energy sources, aligns custom sheet metal fabrication with sustainable and environmentally conscious manufacturing practices.

Answers To Common Questions

Q.What is precision sheet metal fabrication?

A.Precision sheet metal fabrication is the process of cutting, bending, and assembling sheet metal to create custom components with high accuracy.

Q.Who uses custom sheet metal products?

A.Various industries such as automotive, aerospace, electronics, and manufacturing rely on custom sheet metal products for their specific applications.

Q.How is custom sheet metal fabricated to meet specific needs?

A.Custom sheet metal is fabricated using advanced techniques like laser cutting, CNC punching, and forming to ensure precise dimensions and specifications are met.

Q.What if I need a unique design for my sheet metal product?

A.Our team of skilled engineers and fabricators can work with you to develop a custom solution that meets your specific design requirements.

Q.How long does it take to receive custom sheet metal products?

A.The production time for custom sheet metal products varies based on complexity, but our team strives to deliver efficiently without compromising quality.

Q.What are the advantages of using custom sheet metal over off-the-shelf products?

A.Custom sheet metal offers precise fit, tailored design, and material selection, ensuring the end product meets exact requirements for optimal performance.