What You’ll Learn About Custom Laser Cutting Services

By reading this article, you will learn:

– Definition and advantages of custom laser cutting services

– Benefits, applications, and design considerations of custom laser cutting

– How to choose the right custom laser cutting service provider

Custom laser cutting services are an essential aspect of precision sheet metal fabrication, delivering intricate designs and components through advanced laser technology. These services offer numerous advantages over traditional cutting methods and find applications in various industries and fields.

Definition and Purpose of Custom Laser Cutting Services

Custom laser cutting services involve the use of high-powered lasers to precisely cut through materials such as metals, plastics, wood, and glass. The primary purpose is to produce intricate and precise cuts that are often unattainable through conventional cutting methods.

Advantages Over Traditional Cutting Methods

Compared to traditional methods like mechanical cutting or die cutting, custom laser cutting offers unparalleled precision, intricate detailing, and the ability to cut complex shapes with ease. This technology enables the creation of highly customized and detailed components, meeting the specific requirements of the client.

Commonly Served Industries and Applications

Industries such as aerospace, automotive, electronics, and architectural design extensively benefit from custom laser cutting services. Its applications range from creating delicate electronic components to fabricating intricate architectural metalwork.

Understanding the Laser Cutting Process

To fully appreciate the significance of custom laser cutting services, it’s essential to grasp the underlying technology and materials involved.

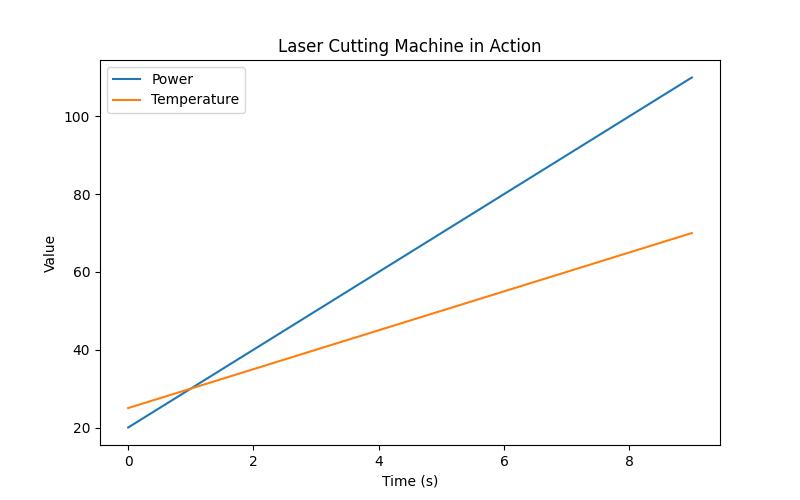

Explanation of Laser Cutting Technology

Laser cutting involves directing the output of a high-powered laser, by computer, at the material to be cut. The intense heat of the laser vaporizes or melts the material, leaving behind a high-quality surface finish.

Types of Lasers Used

The two most common types of lasers used in custom laser cutting are CO2 lasers and fiber lasers. CO2 lasers are well-suited for cutting non-metal materials, while fiber lasers excel in cutting metals with speed and precision.

Materials Suitable for Custom Laser Cutting

Custom laser cutting is suitable for a wide range of materials, including stainless steel, aluminum, acrylic, and wood. This versatility makes it a go-to choice for diverse fabrication needs.

Benefits of Custom Laser Cutting Services

The advantages of custom laser cutting services extend beyond just precision and intricacy. From cost-effectiveness to environmental benefits, these services offer a multitude of advantages.

Precision and Accuracy

Custom laser cutting ensures exceptional precision, intricate detailing, and repeatability, resulting in high-quality finished products that meet the strictest tolerances.

Cost-Effectiveness for Production Runs

With the ability to create complex designs without the need for custom tooling, custom laser cutting proves to be cost-effective, especially for production runs and prototyping.

Reduced Material Wastage and Improved Efficiency

The non-contact nature of laser cutting reduces material wastage and minimizes the need for secondary finishing processes, leading to improved efficiency and material utilization.

| Benefits of Custom Laser Cutting Services | Applications of Custom Laser Cutting |

|---|---|

| Exceptional precision and accuracy | Aerospace components |

| Cost-effectiveness for production runs | Automotive parts |

| Reduced material wastage and improved efficiency | Medical devices |

Applications of Custom Laser Cutting

Custom laser cutting finds extensive applications across various industries, showcasing its versatility and adaptability.

Industries Benefiting from Custom Laser Cutting

Industries such as aerospace, automotive, medical, and consumer electronics rely on custom laser cutting for intricate components, enclosures, and specialized parts.

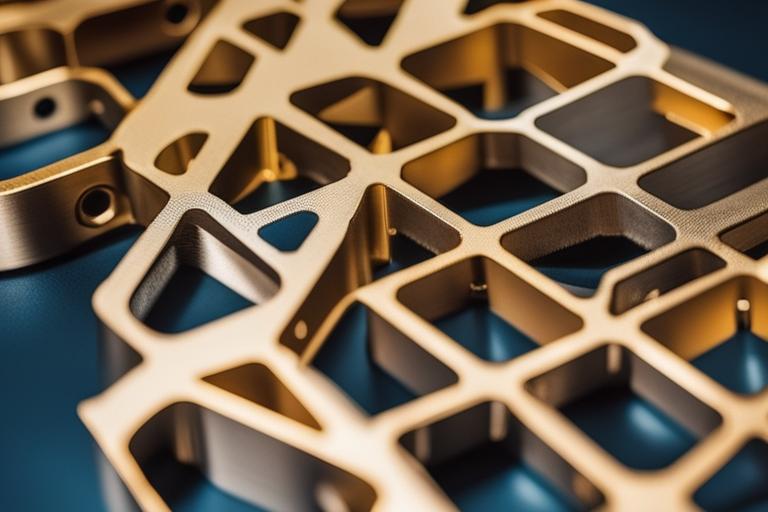

Examples of Intricate Designs and Components

From fine decorative metal screens to precisely cut electronic enclosures, custom laser cutting enables the realization of intricate and complex designs.

Case Studies and Success Stories

Numerous success stories highlight the transformative impact of custom laser cutting, showcasing how it has enabled the creation of groundbreaking products and designs.

Choosing the Right Custom Laser Cutting Service Provider

Selecting the right custom laser cutting service provider is crucial to ensure the quality and precision of the finished components.

Key Considerations in Selecting a Provider

Factors such as experience, technological capabilities, and a proven track record in delivering high-precision components should be key considerations when choosing a service provider.

Quality Assurance and Certifications

Certifications such as ISO 9001 and AS9100 demonstrate a provider’s commitment to quality and adherence to stringent industry standards.

Turnaround Time and Customer Support

Efficient turnaround times and responsive customer support are vital for seamless collaboration and timely project completion.

Design Considerations for Custom Laser Cutting

Thoughtful design plays a pivotal role in maximizing the benefits of custom laser cutting services.

Guidelines for Designing Parts

Designers should consider the capabilities and limitations of laser cutting, utilizing design software to create parts optimized for laser cutting processes.

Maximizing Benefits through Thoughtful Design

By incorporating features such as interlocking tabs and optimized nesting, designers can fully leverage the capabilities of custom laser cutting for efficient production.

Future Trends in Custom Laser Cutting

The integration of AI-driven design optimization and advancements in laser cutting technologies are poised to further enhance the capabilities and efficiency of custom laser cutting services.

Custom Laser Cutting Materials

The choice of materials significantly influences the outcome of laser cutting processes, with a wide array of options available.

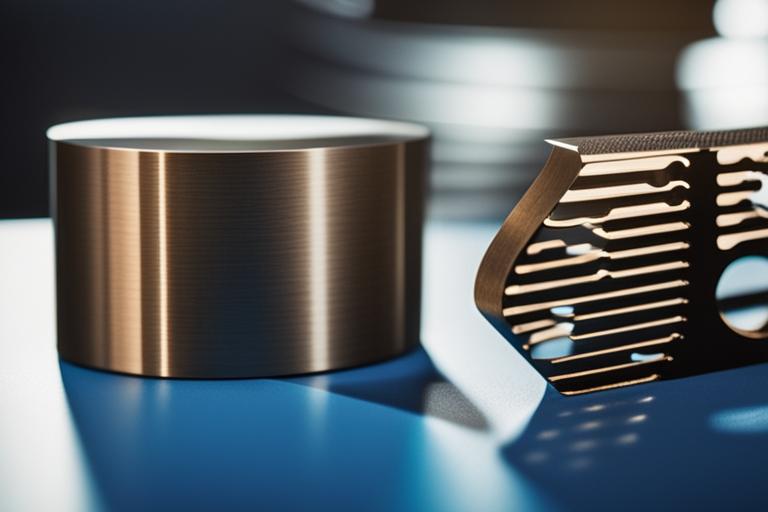

Overview of Materials Suitable for Laser Cutting

From metals like stainless steel and aluminum to non-metals such as acrylic and wood, the versatility of materials suitable for laser cutting is extensive.

Specialized Materials and Surface Finishes

Custom laser cutting also extends to specialized materials like composites and laminates, providing a broad spectrum of finishing options.

Material Compatibility and Limitations

Understanding the compatibility and limitations of different materials is crucial for achieving optimal results in custom laser cutting projects.

Custom Laser Cutting Techniques and Innovations

Advancements in laser cutting technology continue to drive innovation and expand the possibilities in precision sheet metal fabrication.

Latest Advancements in Laser Cutting Technology

Innovations such as beam shaping and adaptive optics are enhancing the precision and speed of laser cutting processes, further expanding its applications.

Potential Innovations and Improvements

Emerging technologies such as ultrafast lasers and hybrid laser systems hold the potential to revolutionize custom laser cutting, opening doors to new possibilities.

Impact of Custom Laser Cutting on Precision Sheet Metal Fabrication

The integration of custom laser cutting services has significantly elevated the standards of precision sheet metal fabrication, enabling the realization of highly intricate and complex designs.

Conclusion

Custom laser cutting services stand as pillars of precision and intricacy in the realm of sheet metal fabrication, offering a myriad of advantages and applications across diverse industries.

Recap of Benefits and Applications

From unparalleled precision to diverse material compatibility, custom laser cutting services continue to redefine the possibilities in fabrication and manufacturing.

Answers To Common Questions

Who provides custom laser cutting services?

Precision sheet metal fabrication companies offer custom laser cutting services.

What materials can be used with custom laser cutting?

Custom laser cutting can be used with various materials such as steel, aluminum, and plastics.

How precise is custom laser cutting?

Custom laser cutting is extremely precise, with accuracy up to 0.1mm, ensuring high-quality results.

Can I request specific designs with custom laser cutting?

Yes, you can request specific designs as precision sheet metal fabricators offer custom solutions.

How can I ensure the quality of custom laser cutting services?

You can ensure quality by checking the company’s past projects and customer reviews.

What if I have a unique project requirement?

Precision sheet metal fabricators can often accommodate unique project requirements through custom laser cutting.