What You Will Learn

- What custom metal fabrication is and its importance

- The techniques and processes in precision sheet metal fabrication

- Tips for choosing a reliable custom metal fabrication partner

I. Introduction to Custom Metal Fabrication

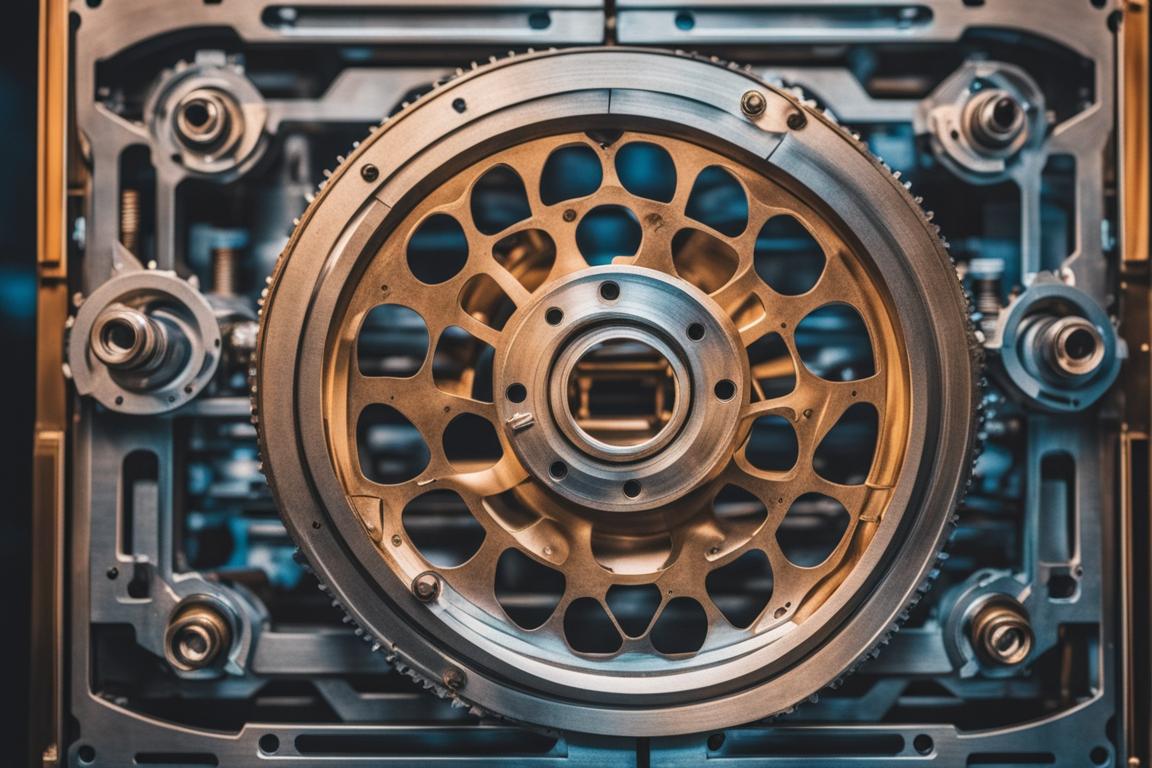

Custom metal fabrication, also known as custom metalwork, refers to the process of creating unique metal structures and components tailored to specific requirements. This intricate craft combines artistry and engineering to produce bespoke metal products that meet the unique needs of diverse industries and projects.

What is Custom Metal Fabrication?

Custom metal fabrication encompasses the design, engineering, and production of metal items that are customized to precise specifications. This can range from small, intricate components to large-scale structural elements, all crafted with meticulous attention to detail.

Importance of Precision and Customization in Metal Fabrication

Precision and customization are fundamental to custom metal fabrication, as they ensure that the final products perfectly align with the intended application. Whether it’s architectural metalwork, industrial machinery components, or specialized parts for aerospace, the ability to tailor the metal fabrication process to exact requirements is paramount.

Meeting the Needs of Diverse Industries and Projects

Custom metal fabrication serves a wide array of industries, including aerospace, automotive, electronics, architecture, and more. By offering bespoke solutions, metal fabricators can address the unique demands of each sector, delivering products that are not only functional but also visually striking and durable.

| Techniques and Processes in Precision Sheet Metal Fabrication | Role of Accuracy and Attention to Detail in Custom Metal Fabrication | Advantages of Precision Sheet Metal Fabrication |

|---|---|---|

| Laser cutting, CNC machining, metal forming | Meticulous attention to detail is required for each cut, bend, and weld | Ability to create complex geometries, tight tolerances, high-quality surface finishes |

II. Understanding Precision Sheet Metal Fabrication

Precision sheet metal fabrication involves the use of cutting-edge techniques and technologies to create intricate metal components with exceptional accuracy and consistency. This specialized approach is essential for producing custom metal parts that demand a high degree of precision.

Techniques and Processes in Precision Sheet Metal Fabrication

Precision sheet metal fabrication encompasses a range of techniques such as laser cutting, CNC machining, and metal forming. These methods enable fabricators to work with various metals, including steel, aluminum, and titanium, to achieve precise shapes and dimensions.

The Role of Accuracy and Attention to Detail in Custom Metal Fabrication

In custom metal fabrication, the minutest details can make a significant difference in the functionality and aesthetics of the final product. Each cut, bend, and weld requires meticulous attention to detail to ensure that the end result meets the exact specifications of the design.

Advantages of Precision Sheet Metal Fabrication

The advantages of precision sheet metal fabrication are numerous, including the ability to create complex geometries, tight tolerances, and high-quality surface finishes. These capabilities make it an ideal choice for industries that demand intricate, customized metal components.

Custom metal fabrication is a specialized process that involves the creation of metal structures and components tailored to specific requirements. This intricate craft combines artistry and engineering to produce bespoke metal products that meet the unique needs of diverse industries and projects. Custom metal fabrication encompasses the design, engineering, and production of metal items that are customized to precise specifications. This can range from small, intricate components to large-scale structural elements, all crafted with meticulous attention to detail.

Questions and Answers

What is precision sheet metal fabrication?

Precision sheet metal fabrication is the process of shaping and manipulating metal sheets to create custom parts and components with high accuracy and tight tolerances.

Who can benefit from custom metal fabrication?

Industries such as aerospace, automotive, electronics, and medical equipment can benefit from custom metal fabrication to create unique and specialized components.

How is custom metal fabrication different from standard fabrication?

Custom metal fabrication involves creating unique, tailor-made metal parts and components, while standard fabrication typically focuses on mass-producing standardized items.

What are the advantages of precision sheet metal fabrication?

Precision sheet metal fabrication offers high accuracy, tight tolerances, and the ability to create complex and customized metal parts for specific applications.

How can I ensure the quality of custom metal fabrication?

To ensure quality, look for a fabrication provider with extensive experience, advanced technology, and a proven track record in delivering precise and reliable metal fabrication solutions.

But isn’t custom metal fabrication expensive?

While custom metal fabrication may have higher initial costs, it offers long-term benefits such as precise component fit, reduced assembly time, and improved overall product performance, making it a valuable investment.