Let’s cut to the chasesheet metal punching is nothing short of a marvel in the precision sheet metal fabrication world. It’s that critical process where science meets raw power, creating holes and shapes with a finesse that borders on artistry. And when it comes to Tempco’s mastery of this craft, it’s not just about making a hole; it’s about making a statement of precision, efficiency, and cost-effectiveness.

What You’ll Learn about Sheet Metal Punching

By reading this article, you will learn about the capabilities, materials, tolerances, equipment, applications, advantages, limitations, and services related to sheet metal punching.

– Capabilities: Sheet metal punching allows for precise hole punching and forming in various sizes and shapes.

– Materials: Sheet metal punching can be used on a wide range of materials, including aluminum, steel, and stainless steel.

– Tolerances: Sheet metal punching processes can achieve tight tolerances, ensuring high precision in the final product.

Sheet Metal Punching Capabilities

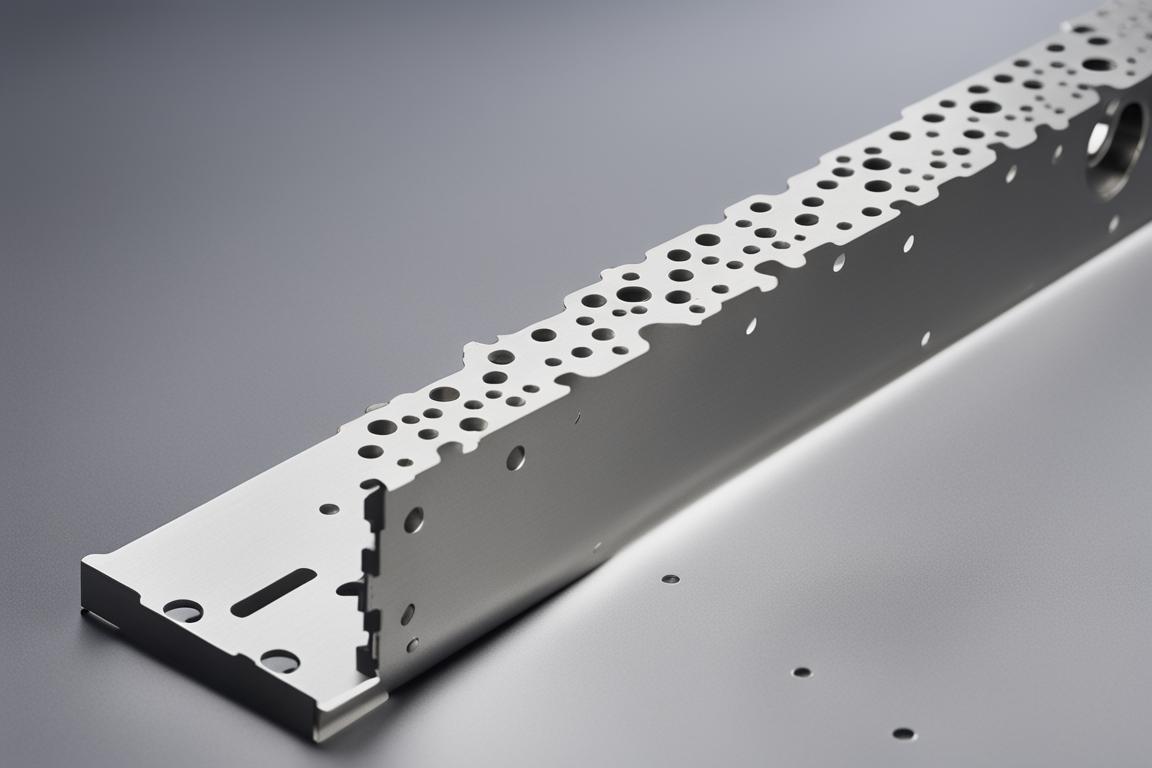

When discussing the capabilities of sheet metal punching, I’m immediately reminded of a project that came through Tempco’s doorsa demanding design requiring an array of perforations and intricate cut-outs. This is where the capabilities of sheet metal punching truly shine. Tempco’s high-speed machines are like well-oiled athletes, capable of delivering rapid, repeatable punches with a precision that’s almost superhuman. They can handle sheets of varying thicknesses, punching holes as small as a pinprick to as large as a fist, all while maintaining tolerances tighter than a drum.

Insider Tip: Always consider the material thickness and type when planning your designthis will impact the punching capability and the tooling required.

Tempco’s equipment is state-of-the-art, including CNC turret punches and high-precision fabricators that can churn out complex, multi-hit patterns with ease. Their capabilities are not just about punching; they extend to forming, embossing, and other complex operations that can be executed within the same setup, reducing the need for multiple stages of production.

Sheet Metal Punching Materials

The versatility of sheet metal punching is also reflected in the range of materials it can tame. Tempco doesn’t flinch, whether it’s aluminum, which punches like a dream, or stainless steel, which demands respect and the right tooling to avoid deformations. Brass, copper, and various alloys also fall in line under Tempco’s expert handling.

I recall a project that involved punching delicate patterns into a thin copper sheet. The concern for material integrity was paramount, yet Tempco’s precise control and understanding of material properties led to a flawless execution.

Insider Tip: When working with softer metals like copper or aluminum, special considerations for clearance and punch size are crucial to avoid burrs or material distortion.

Sheet Metal Punching Tolerances

Tolerances in sheet metal punching can make or break a project. I’ve seen Tempco work miracles, maintaining tolerances that would make a Swiss watchmaker nod in approval. They talk in thousandths of an inch, and their machines listen. This precision ensures parts fit together seamlessly in assemblies, crucial for applications where even a hair’s breadth of difference means failure.

Insider Tip: Always communicate the importance of specific tolerances in your project upfront to ensure the punching process is tailored to your needs.

Understanding the interplay between material type, thickness, and punch tooling is essential for achieving these tight tolerances. Tempco’s technicians are more than operators; they’re maestros of metal who know precisely what levers to pull to keep those tolerances tight.

Sheet Metal Punching Equipment

In Tempco’s arsenal, the sheet metal punching equipment is not just impressiveit’s downright intimidating in its capability. CNC-controlled turret punches with auto-indexing stations, high-speed servos, and quick-change tooling systems are the backbone of Tempco’s punching services. These machines are meticulously maintained, calibrated, and upgraded, ensuring they’re always at the cutting edge of technology.

I’ve witnessed the sheer adaptability of these machines, seamlessly transitioning between jobs with minimal downtime. This adaptability translates into cost savings and lead time reductions for clients, which, in the world of manufacturing, are the golden tickets.

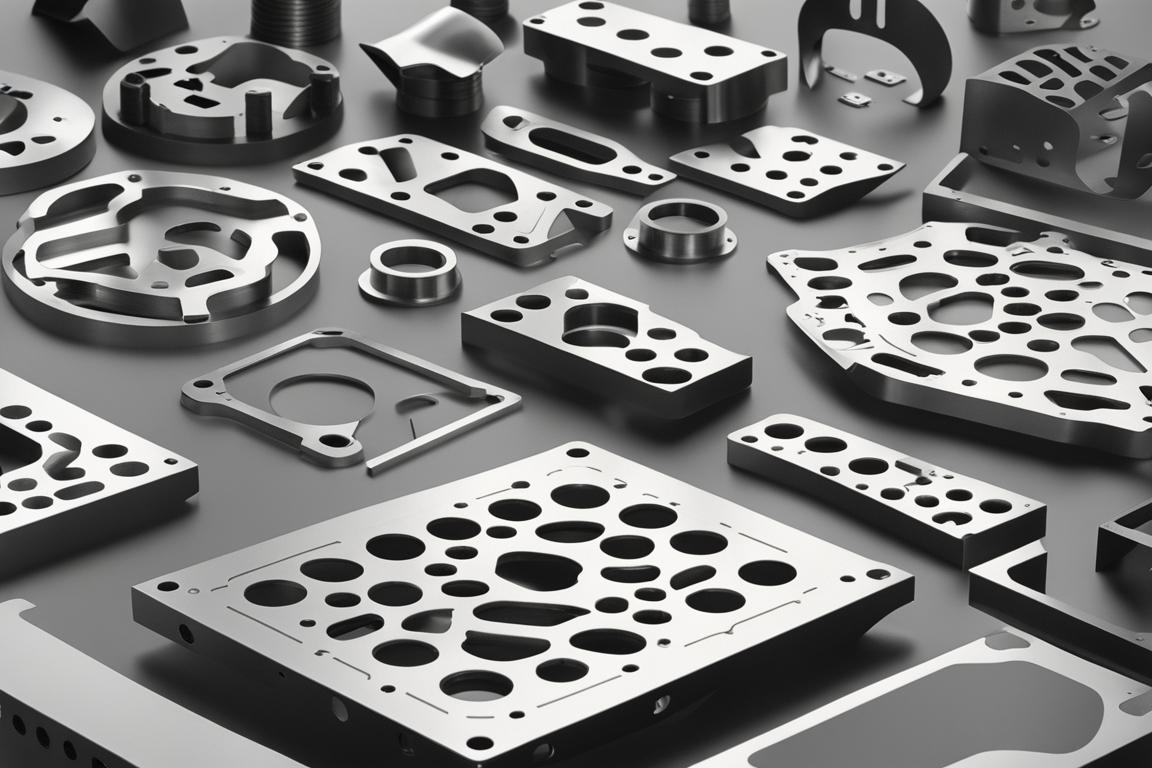

Sheet Metal Punching Applications

From aerospace to electronics, the applications of sheet metal punching are vast and varied. Tempco’s portfolio boasts an array of projects that would make any metal fabricator envious. I’ve seen them craft intricate components for medical devices that demand surgical precision and robust panels for heavy machinery that can withstand the wrath of the elements.

Insider Tip: Leverage the versatility of punching for multi-functional designsincorporate tabs, louvers, and countersinks to add utility to your punched parts.

The beauty of sheet metal punching is not just what it can make but also what it enables. Each punched part can become a vital piece of a larger puzzle, contributing to innovations that drive industries forward.

Sheet Metal Punching Advantages

The advantages of Tempco’s sheet metal punching services are clear and compelling. Speed is a giventhe rapid processing times of their machines translate directly into productivity gains. But it’s the consistency of quality that truly sets them apart. With each punch, the outcome is predictably perfect, a trait that’s invaluable when producing large volumes.

Cost-effectiveness is another significant advantage. The tooling for punching, while an investment, is more economical in the long run compared to other processes like laser cutting, especially for larger production runs. And let’s not forget the material savingspunching can be optimized to minimize waste, making the most out of every inch of sheet metal.

Sheet Metal Punching Limitations

But even superheroes have their kryptonite, and sheet metal punching is no exception. One limitation that comes to mind is the strain punching can place on materials, potentially leading to distortions if not managed correctly. And while the tooling offers cost advantages, it can also be a constraint, requiring a lead time and investment that may not align with all project timelines or budgets.

Insider Tip: When dealing with complex or unique shapes, consider the cost and time of custom toolingsometimes alternative fabrication methods may be more viable.

Furthermore, the very nature of punching means that it’s not always suitable for extremely complex or delicate geometries where the risk of material compromise is high. For these scenarios, complementary processes like laser cutting or waterjet cutting might be the heroes.

Sheet Metal Punching Services from Tempco

Tempco’s sheet metal punching services stand out in a crowded marketplace of metal fabricators. They’ve fine-tuned their process to a symphony of precision and efficiency, understanding that it’s not just about punching holesit’s about crafting solutions tailored to customer needs.

Their consultative approach, taking the time to understand the intricacies of each project, coupled with their relentless pursuit of perfection, makes Tempco a partner, not just a provider. They’re the kind of company that doesn’t just deliver a part; they deliver peace of mind, knowing that each punch, each bend, each cut, contributes to the success of your project.

In conclusion, if you’re seeking a sheet metal punching service that combines the raw power of industry-leading machinery with the delicate touch of craftsmanship, look no further than Tempco Manufacturing. Their commitment to precision, versatility, and efficiency makes them a formidable force in the realm of precision sheet metal fabrication. Whether you’re dealing with a high-volume production run or a complex, one-off prototype, their punching services are calibrated to hit the mark every time, proving that in the world of metal, Tempco doesn’t just punch above their weightthey set the standard.

For more insights and updates on sheet metal punching, you can delve into Tempco’s rich reservoir of knowledge through their blog posts and stay ahead of the curve in this dynamic field.

FAQs

Question: Who uses sheet metal punching in precision sheet metal fabrication?

Answer: Precision sheet metal fabricators use sheet metal punching to create precise holes and shapes in metal sheets.

Question: What is sheet metal punching in precision sheet metal fabrication?

Answer: Sheet metal punching is a process of using a punch and die to cut holes or shapes in sheet metal with high precision.

Question: How does sheet metal punching contribute to precision fabrication?

Answer: Sheet metal punching allows for accurate and repeatable production of intricate shapes and patterns in sheet metal components.

Question: What if I need a custom shape that can’t be punched?

Answer: For custom shapes, precision sheet metal fabrication also offers laser cutting and other machining processes to meet specific requirements.

Question: How can sheet metal punching improve production efficiency?

Answer: Sheet metal punching reduces production time and material waste by creating precise holes and shapes in a single operation, leading to increased efficiency.

Question: What if I need smooth edges on punched sheet metal parts?

Answer: Precision sheet metal fabrication includes deburring and finishing processes to ensure smooth and polished edges on punched sheet metal parts.