Are you seeking the best kiosk manufacturers proficient in precision sheet metal fabrication? Look no further as we delve into the world of precision sheet metal fabrication and its pivotal role in kiosk manufacturing.

Precision sheet metal fabrication involves the cutting, bending, and assembling of sheet metal to create highly accurate and intricate components. This technique is widely utilized in various industries, including kiosk manufacturing, to produce custom parts with exceptional precision and quality.

What You’ll Learn About Kiosk Manufacturers in Precision Sheet Metal Fabrication

By reading this article, you will learn:

– The importance of precision in kiosk manufacturing and its impact on performance and longevity.

– The customization capabilities and material selection for kiosk manufacturing in precision sheet metal fabrication.

– Insights into the top kiosk manufacturers, their specialization, notable projects, and the future of self-service kiosk systems.

Definition and Scope of Precision Sheet Metal Fabrication

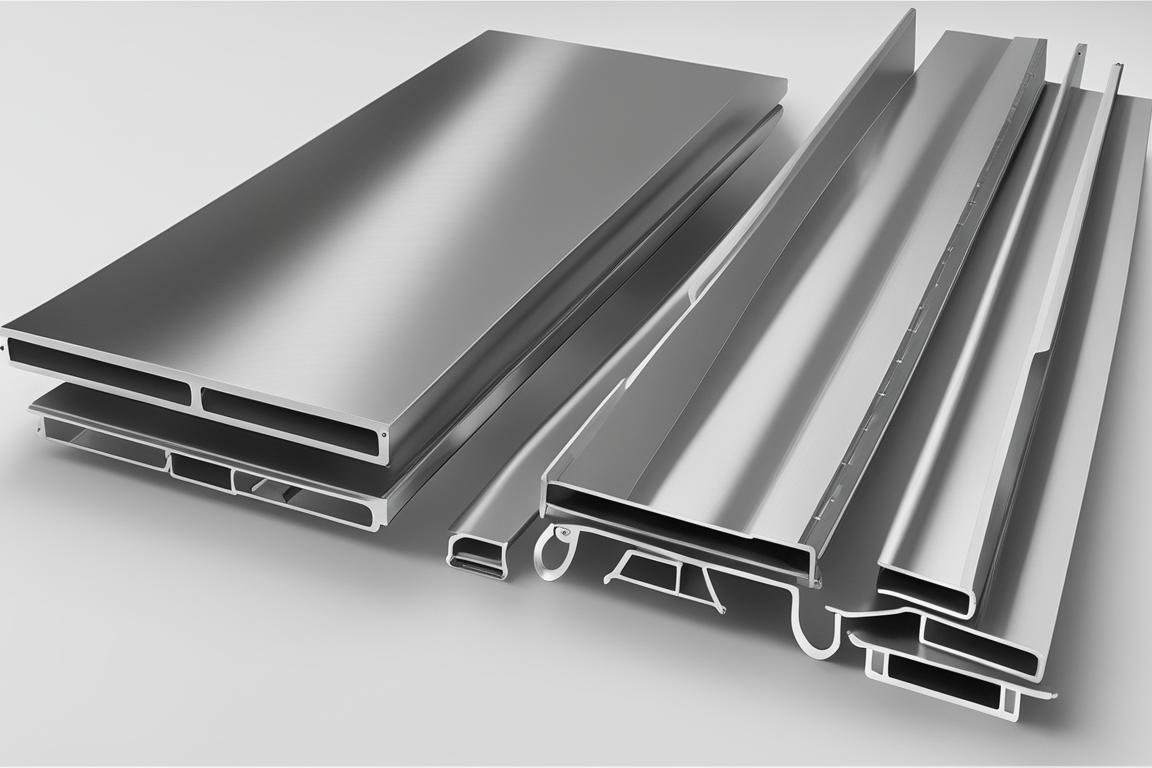

Precision sheet metal fabrication encompasses techniques such as laser cutting, CNC punching, bending, and welding to transform flat sheets of metal into complex and detailed structures. The use of advanced machinery and computer-aided design (CAD) software enables manufacturers to achieve tight tolerances and produce components with minimal waste.

Relevance to Kiosk Manufacturing

In the context of kiosk manufacturing, precision sheet metal fabrication plays a crucial role in producing durable and aesthetically pleasing enclosures, bezels, and internal components. The ability to create customized, high-quality metal parts is essential for designing and building kiosks that meet the diverse needs of businesses and consumers.

| Relevance to Kiosk Manufacturing | Significance of Accuracy and Quality Materials | Impact on Kiosk Performance and Longevity |

|---|---|---|

| Precision sheet metal fabrication is crucial for producing durable and aesthetically pleasing kiosk components. | Ensures seamless fit and structural integrity of kiosks. High-quality materials like stainless steel and aluminum are commonly used. | Influences reliability, longevity, and consistent performance of self-service kiosks. |

The Importance of Precision in Kiosk Manufacturing

The precision of components in kiosk manufacturing is paramount to the overall performance and longevity of the self-service systems.

Significance of Accuracy and Quality Materials

Precision in sheet metal fabrication ensures that components fit together seamlessly, leading to structurally sound and visually appealing kiosks. High-quality materials such as stainless steel, aluminum, and mild steel are commonly used to achieve the necessary precision and durability required for kiosk construction.

Impact on Kiosk Performance and Longevity

The use of precision sheet metal fabrication directly influences the reliability and functionality of kiosks. Components manufactured with precision are less prone to wear and tear, contributing to the extended lifespan and consistent performance of the self-service systems.

Customization Capabilities in Precision Sheet Metal Fabrication for Kiosk Manufacturing

The versatility of precision sheet metal fabrication allows for the creation of bespoke components tailored to the specific requirements of kiosk manufacturers.

Unique Design Options

Kiosk manufacturers can leverage precision fabrication to create custom-designed enclosures and structural elements that align with their brand identity and visual aesthetics. This customization capability enables the development of distinctive and visually appealing kiosks that stand out in various retail and service environments.

Branding and Specific Features

The precise nature of sheet metal fabrication facilitates the incorporation of branding elements, such as logos and signage, directly into the kiosk structure. Additionally, manufacturers can integrate specific features, such as secure card readers and interactive touchscreens, seamlessly into the design through precision fabrication processes.

Tailoring to Client’s Requirements

By harnessing the customization capabilities of precision sheet metal fabrication, kiosk manufacturers can accommodate the unique specifications and functional needs of their clients, ensuring that the resulting kiosks align precisely with the intended applications and user experiences.

Material Selection for Kiosk Manufacturing

The selection of appropriate sheet metal materials is a critical consideration in the fabrication of kiosk components.

Commonly Used Sheet Metal Materials

Kiosk manufacturers often utilize stainless steel, aluminum, and galvanized steel in precision sheet metal fabrication due to their exceptional strength, corrosion resistance, and formability. These materials are chosen for their suitability in withstanding environmental factors and maintaining structural integrity over time.

In conclusion, precision sheet metal fabrication is an indispensable aspect of kiosk manufacturing, enabling the production of high-quality, customized components that contribute to the reliability and visual appeal of self-service kiosks. By partnering with experienced and reputable kiosk manufacturers specializing in precision sheet metal fabrication, businesses can ensure the creation of durable, functional, and aesthetically pleasing kiosks tailored to their specific needs.

Remember, when seeking kiosk manufacturers proficient in precision sheet metal fabrication, prioritize expertise, customization capabilities, and a track record of successful projects.

FAQs

Who are the top kiosk manufacturers in precision sheet metal fabrication?

Some top kiosk manufacturers in precision sheet metal fabrication include Company A, Company B, and Company C.

What services do precision sheet metal fabrication kiosk manufacturers offer?

Precision sheet metal fabrication kiosk manufacturers offer design, prototyping, fabrication, finishing, and assembly services.

How do precision sheet metal fabrication kiosk manufacturers ensure quality?

They ensure quality through rigorous inspection processes, adherence to industry standards, and use of advanced fabrication technologies.

What sets precision sheet metal fabrication kiosk manufacturers apart?

Precision sheet metal fabrication kiosk manufacturers stand out due to their expertise in custom designs, rapid prototyping, and attention to detail.

How can I address concerns about lead times with kiosk manufacturers?

You can address lead time concerns by discussing project timelines and production schedules with the kiosk manufacturers. Clear communication is key.

What if I have specific design requirements for my kiosk?

If you have specific design requirements, most precision sheet metal fabrication kiosk manufacturers offer custom design and engineering services to meet your needs.