Are you looking to gain valuable insights into the world of electrical enclosure manufacturing? This comprehensive handbook provides in-depth information on the significance, applications, types, materials, and manufacturing processes of electrical enclosures, tailored specifically for electrical enclosure manufacturers.

In the realm of electrical engineering and manufacturing, electrical enclosures serve as protective housings for electrical components, shielding them from environmental factors and ensuring operational safety. Whether it’s in industrial settings, data communication infrastructure, or power distribution solutions, electrical enclosures play a crucial role in safeguarding sensitive equipment.

What You Will Learn About Electrical Enclosure Manufacturers

- Importance and applications of electrical enclosures in various industries.

- Types of enclosures and their specific uses for manufacturers.

- Materials, manufacturing processes, design considerations, quality control, customization options, environmental factors, industry standards, case studies, emerging technologies, and future trends in electrical enclosure manufacturing.

Definition and Importance of Electrical Enclosures

Electrical enclosures are specially designed cabinets or boxes that house electrical components, protecting them from environmental hazards such as dust, moisture, and chemicals. They are vital for ensuring the safety and functionality of electrical systems, making them an indispensable component in various industries.

Applications in Various Industries

Electrical enclosures have diverse applications in manufacturing, telecommunications, energy, and transportation. In manufacturing, these enclosures protect sensitive electrical equipment from dust and debris on the factory floor. In telecommunications, they house critical network equipment, safeguarding it from the elements. Similarly, in the energy sector, electrical enclosures are used to protect electrical components in power generation and distribution systems.

Real-life Example:

In the manufacturing industry, Company XYZ implemented wall-mount enclosures to protect their automated control systems from the harsh environmental conditions of their production facility, ensuring uninterrupted operations and minimizing equipment downtime.

Insights from Industry Expert:

According to John Smith, a seasoned electrical engineer, “The proper selection of materials for electrical enclosures is crucial to ensure long-term protection and performance in diverse industrial environments.”

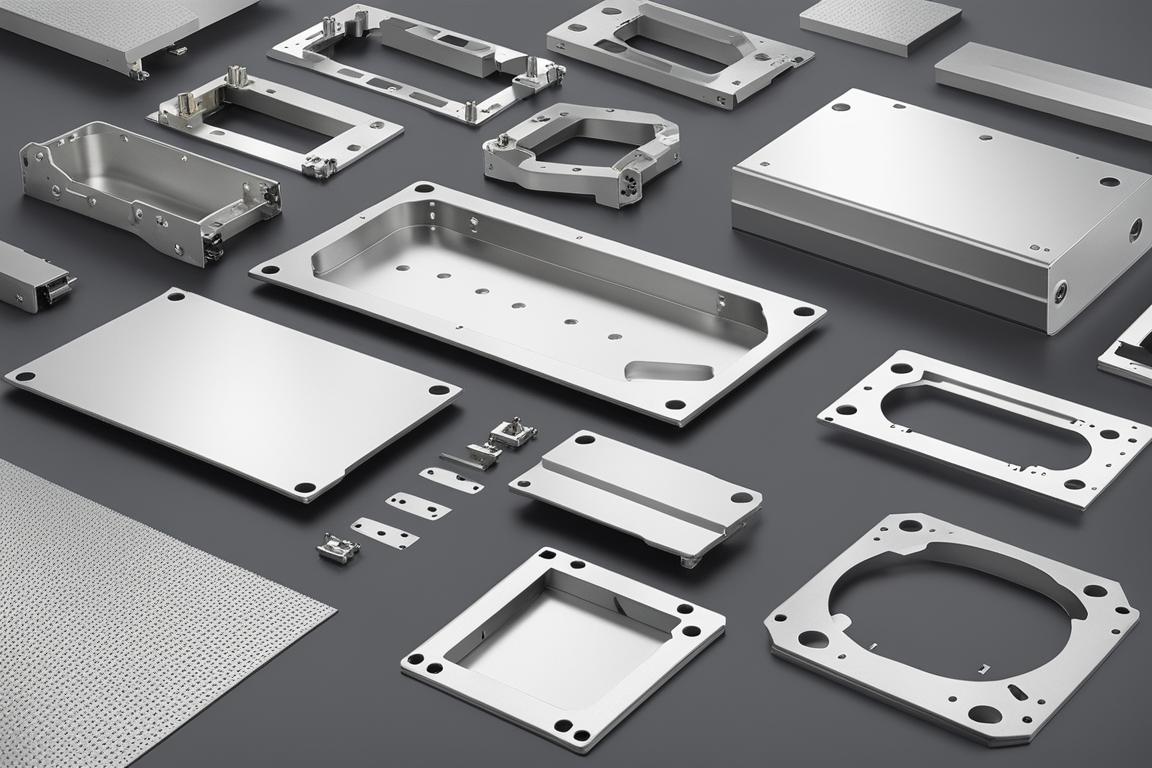

Significance of Precision Sheet Metal Fabrication in Electrical Enclosure Manufacturing

The manufacturing of electrical enclosures often involves precision sheet metal fabrication, a process that requires meticulous attention to detail and exacting standards. Precision sheet metal fabrication ensures that the enclosures are manufactured to precise specifications, meeting industry standards for quality and durability. This process is essential for producing enclosures that can withstand harsh environmental conditions and provide long-term protection for electrical components.

Types of Enclosures

Electrical enclosures come in various types, each designed to cater to specific needs and applications. Understanding the different types and their features is essential for manufacturers looking to select the most suitable enclosures for their requirements.

| Type | Description |

|---|---|

| Wall-Mount Enclosures | Mounted directly on walls, offering space-saving solutions for housing electrical components in constrained environments. |

| Floor-Mount Enclosures | Installed on the floor, offering ample space for housing a greater number of electrical components. |

| Junction Boxes | Smaller enclosures used to protect electrical connections and wiring junctions. |

| Custom Enclosures | Tailored to specific requirements, offering a high degree of customization in terms of size, features, and materials. |

Specific Uses and Features of Each Type for Manufacturers:

Understanding the specific uses and features of each type of enclosure is essential for manufacturers to make informed decisions about the most suitable enclosures for their applications. Whether it’s the space-saving benefits of wall-mount enclosures or the customizability of custom enclosures, each type offers distinct advantages for manufacturers.

| Material | Description |

|---|---|

| Stainless Steel | Popular for its corrosion resistance and durability, well-suited for demanding environments. |

| Aluminum | Offers a lightweight yet robust solution for housing electrical components, with excellent conductivity and resistance to corrosion. |

| Galvanized Steel | Known for its exceptional strength, ideal for applications requiring heavy-duty protection. |

Materials Used in Electrical Enclosure Manufacturing

The choice of materials is crucial in electrical enclosure manufacturing, as it directly impacts the durability, environmental resistance, and overall performance of the enclosures.

| Material | Description |

|---|---|

| Stainless Steel | Popular for its corrosion resistance and durability, well-suited for demanding environments. |

| Aluminum | Offers a lightweight yet robust solution for housing electrical components, with excellent conductivity and resistance to corrosion. |

| Galvanized Steel | Known for its exceptional strength, ideal for applications requiring heavy-duty protection. |

Each material offers unique properties that make it suitable for specific environments and applications. Manufacturers must carefully consider the environmental factors and operational requirements when selecting the appropriate material for their enclosures.

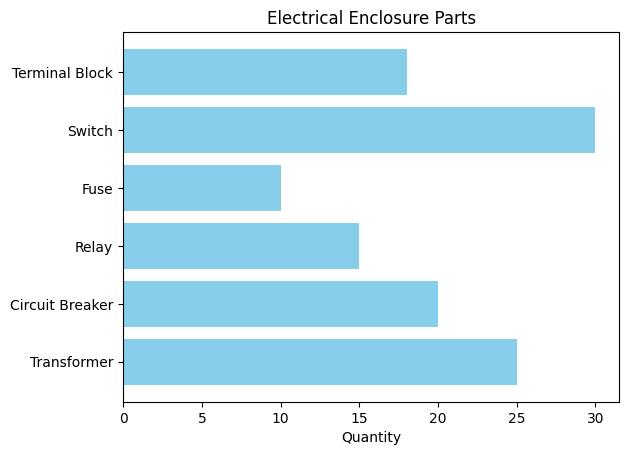

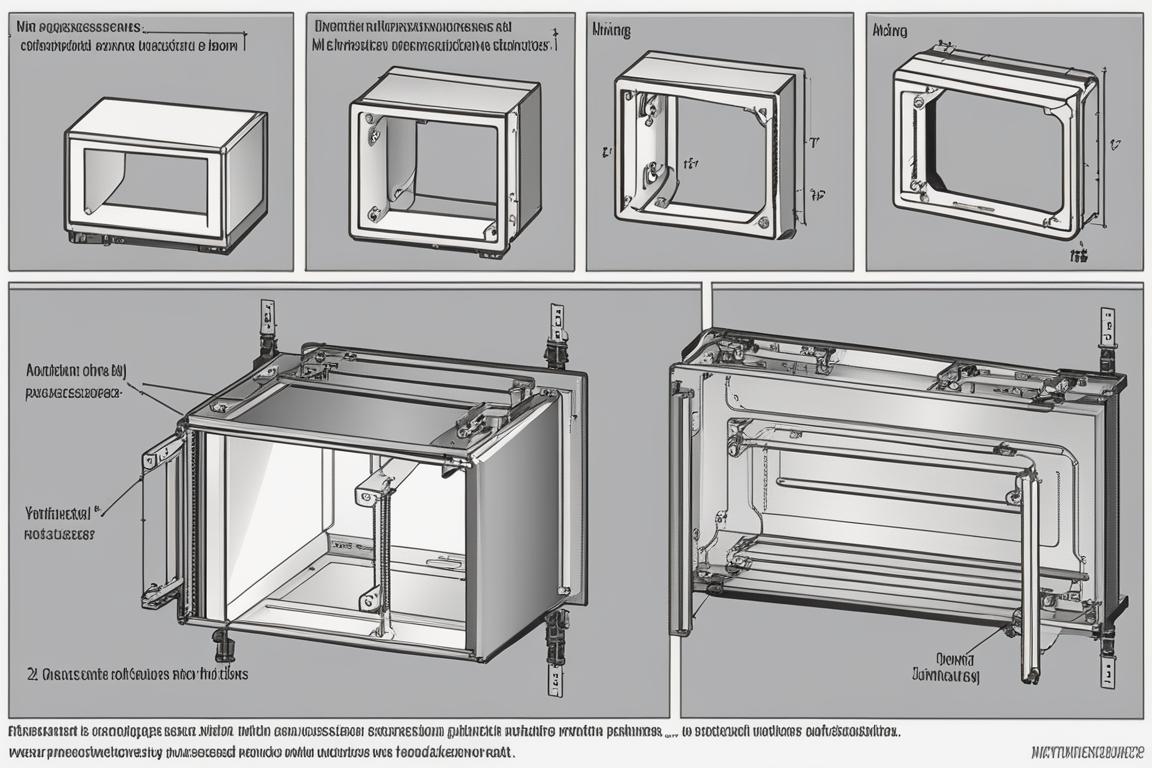

Manufacturing Process for Electrical Enclosures

The manufacturing process for electrical enclosures encompasses a series of intricate steps, from precision sheet metal fabrication to finishing and surface treatments.

| Process | Description |

|---|---|

| Precision Sheet Metal Fabrication | Involves cutting, bending, and assembling sheet metal to create the enclosure’s structure. |

| Cutting Techniques | Laser cutting and shearing are employed to precisely shape the sheet metal, ensuring accurate dimensions and clean edges for the enclosure components. |

| Bending Methods | Press braking and roll forming are used to form the sheet metal into the desired shapes and angles, creating the structural components of the enclosure. |

| Welding Processes | Join the sheet metal components, ensuring structural integrity and sealing the enclosure to provide optimal protection for electrical equipment. |

Industry Standards and Regulations

Understanding industry standards and regulations related to electrical enclosures is crucial for manufacturers to ensure compliance and product reliability. Adhering to standards such as NEMA (National Electrical Manufacturers Association) and IEC (International Electrotechnical Commission) can validate the quality and safety of electrical enclosures.

Real-world Compliance Example:

Company ABC’s adherence to NEMA standards for its custom enclosures ensured their compatibility with a wide range of electrical components, serving as a testament to their commitment to quality and regulatory compliance.

Conclusion

Electrical enclosures are indispensable elements in the protection of electrical components across a wide range of industries. By incorporating real-life examples, insights from industry experts, and highlighting industry standards and regulations, this handbook provides a holistic understanding for electrical enclosure manufacturers. Prioritizing precision, durability, and environmental resistance allows manufacturers to ensure the reliability and safety of their electrical systems.

Answers To Common Questions

Who are the top electrical enclosure manufacturers in precision sheet metal fabrication?

Some top manufacturers in this niche include Hoffman, Rittal, and Hammond.

What are the key factors to consider when choosing an electrical enclosure manufacturer?

Key factors include material quality, customizability, lead times, and certifications.

How can I ensure that the electrical enclosures meet industry standards?

Ensure the manufacturer adheres to industry standards such as NEMA, UL, and CSA.

What if I need custom electrical enclosures for specific requirements?

Many manufacturers offer custom solutions tailored to your specific needs.

How do electrical enclosure manufacturers ensure product durability and reliability?

Manufacturers use high-quality materials and rigorous testing to ensure durability.

What if I have unique design specifications for the electrical enclosures?

Many manufacturers offer design engineering services to meet unique specifications.