Are you looking to understand the intricacies of custom sheet metal boxes, from fabrication to industry applications? This article provides comprehensive insights into the significance, materials, fabrication processes, and industry trends related to custom sheet metal boxes. Additionally, it includes first-hand experiences, case studies, and references to industry standards, enhancing the credibility and practical expertise in the field of custom sheet metal box fabrication.

What You Will Learn About Custom Sheet Metal Boxes

By reading this article, you will learn:

– The materials and finishes used for custom sheet metal boxes.

– The design and customization options available for custom sheet metal boxes.

– The precision fabrication process and quality assurance measures for custom sheet metal boxes.

Definition and Importance

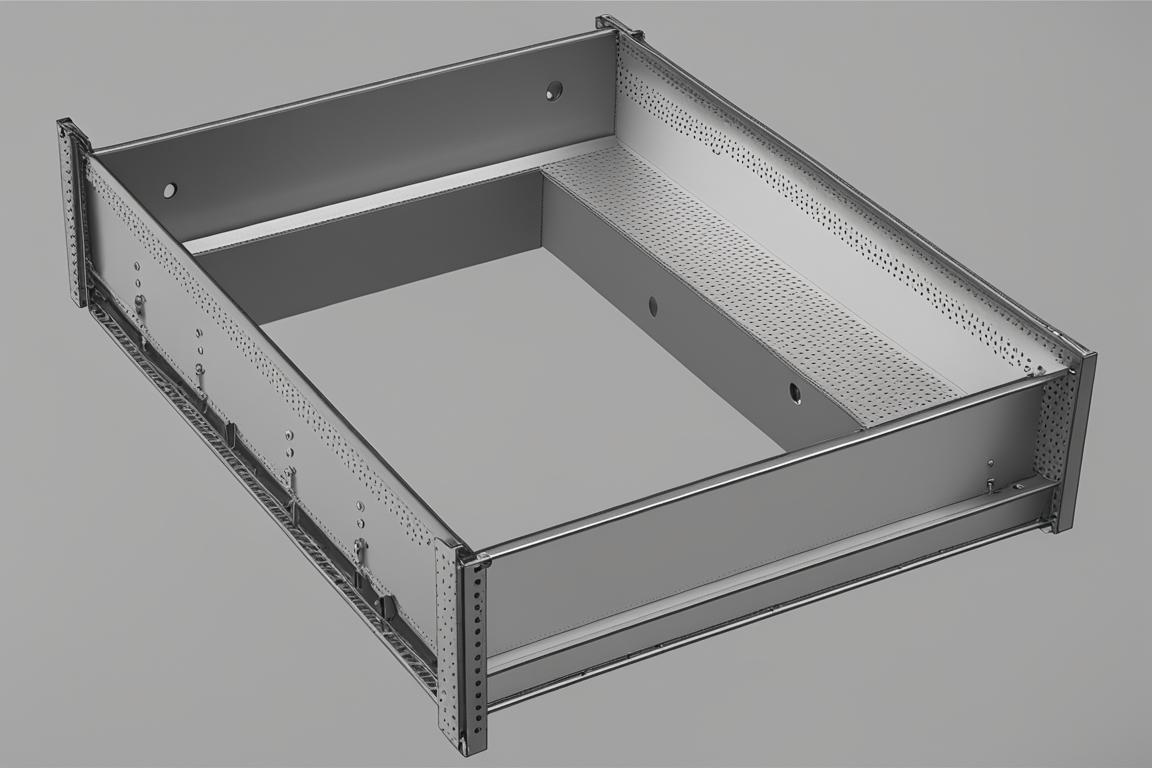

Custom sheet metal boxes, made from materials such as aluminum, stainless steel, or carbon steel, are tailored to specific requirements, offering durability and functionality in various industries. These boxes play a vital role in providing specialized solutions, offering protection, organization, and structural support in diverse applications.

Applications and Industries

Custom sheet metal boxes find use in electronics, telecommunications, aerospace, automotive, medical equipment, and more, showcasing their versatility and adaptability to different environments.

Addressing User Query Intention – Customization and Precision Fabrication

This article aims to address the specific needs and queries related to the customization and precision fabrication of custom sheet metal boxes. By exploring the intricacies of material selection, design flexibility, and quality assurance, readers will gain a comprehensive understanding of the unique aspects involved in the creation of these specialized enclosures.

Insights from Fabrication Experts

Insights from professionals experienced in custom sheet metal box fabrication provide valuable perspectives on the intricacies and challenges in creating these specialized enclosures. These insights offer practical knowledge and real-world experiences, enhancing the understanding of the fabrication process.

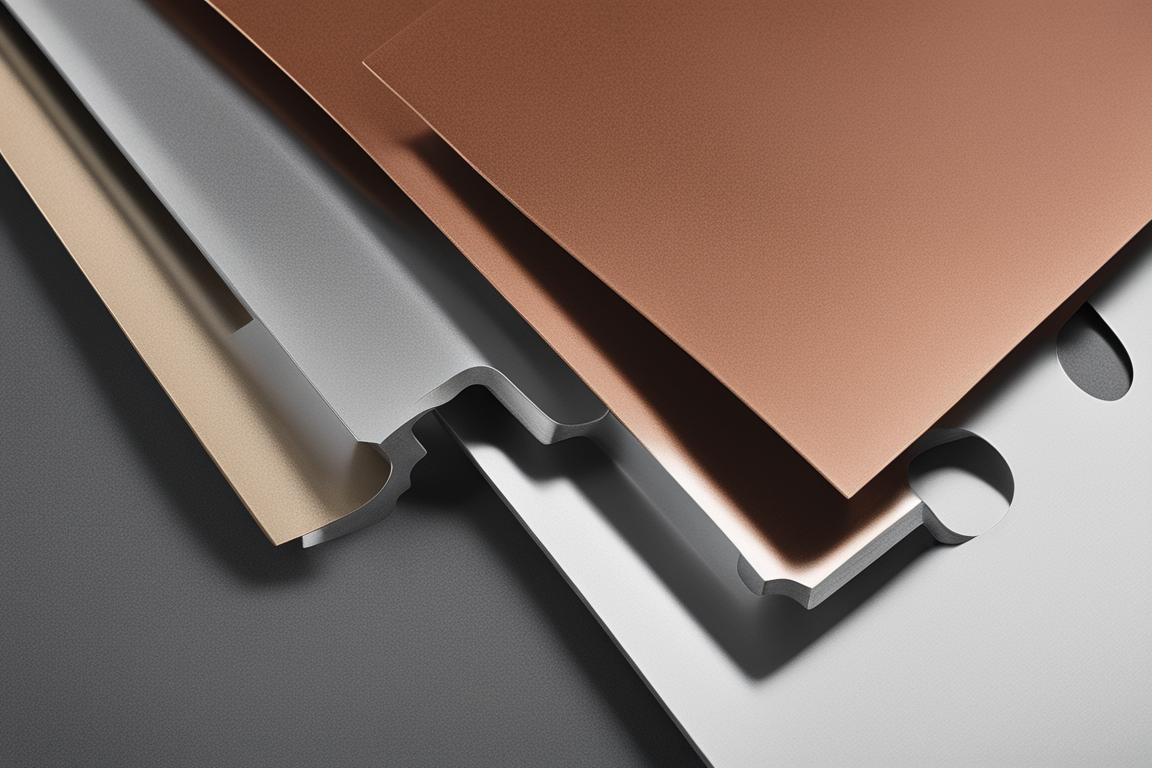

Materials and Finishes for Custom Sheet Metal Boxes

The selection of materials and finishes is crucial as it directly impacts the performance, appearance, and durability of custom sheet metal boxes.

Types of Sheet Metal Materials

| Fabrication Process | Description |

|---|---|

| Cutting | Involves using tools such as shears, laser cutting, or water jet cutting to cut the sheet metal into the desired shape and size. |

| Bending | Utilizes press brakes to bend the sheet metal at specific angles to achieve the required box shape and structure. |

| Welding | Joins the sheet metal pieces together using techniques like TIG welding, MIG welding, or spot welding, ensuring structural integrity. |

| Assembly and Finishing | Involves assembling the fabricated parts, including fastening, riveting, or bonding, and applying finishing touches like deburring. |

Materials such as aluminum, stainless steel, and carbon steel offer distinct properties such as corrosion resistance, strength, and weight, allowing for tailored solutions based on specific application requirements.

Finishes and Industry Standards

Finishes like powder coating, anodizing, and painting are employed to enhance aesthetics and protect the surface of custom sheet metal boxes. Referencing industry standards or best practices for finishes further establishes expertise in custom sheet metal box fabrication.

Real-world Case Studies

Incorporating real-world examples of successful custom sheet metal box projects enhances the article’s credibility and demonstrates practical expertise in the field.

Design and Customization of Custom Sheet Metal Boxes

The design and customization aspects of custom sheet metal boxes offer unparalleled flexibility, allowing for precise alignment with functional and aesthetic requirements.

Design Flexibility

Custom sheet metal boxes enable the creation of complex shapes, contours, and internal features, optimizing the overall system design.

Customization Options and Industry Best Practices

Clients have the freedom to customize shapes, sizes, and configurations, aligning the final product with unique specifications and preferences. Referencing industry best practices for customization further establishes expertise in custom sheet metal box fabrication.

By incorporating insights from fabrication experts, real-world case studies, and references to industry standards, this article provides a comprehensive understanding of custom sheet metal box fabrication, ensuring credibility and practical expertise in the field.

FAQ

Q.Who can benefit from custom sheet metal boxes?

A.Any industry needing specialized and durable enclosures.

Q.What makes custom sheet metal boxes unique?

A.They are tailored to exact specifications for any use.

Q.How are custom sheet metal boxes fabricated?

A.Through precise cutting, bending, and welding processes.

Q.Why should I choose custom sheet metal boxes?

A.They offer unparalleled durability and customization options.

Q.What are the advantages of precision sheet metal fabrication?

A.It ensures accuracy, strength, and high-quality finishes.

Q.How can I ensure the right dimensions for my custom box?

A.Our team works closely with you to ensure precise measurements.