What You’ll Learn About Custom Metal Fabrication

By reading this article, you will learn:

1. Definition, significance, and versatility of custom metal fabrication in various industries.

2. Range of services offered, including CNC punching, bending, welding, and finishing, as well as working with various metals like stainless steel, aluminum, copper, titanium, and brass.

3. Importance of strong client relationships, quality control, compliance standards, and future trends in custom metal fabrication.

Custom metal fabrication, also known as custom metal manufacturing, is the process of creating metal structures and components tailored to the specific needs of diverse industries. It involves cutting, bending, and assembling techniques, shaping modern manufacturing and construction landscapes.

What Is Custom Metal Fabrication, and Why Is It Important?

Definition of Custom Metal Fabrication

Custom metal fabrication involves designing, cutting, shaping, and assembling metal components to create unique products tailored to clients’ precise specifications.

Importance of Custom Metal Fabrication in Various Industries

Custom metal fabrication is essential across industries, serving as the backbone of precision engineering and manufacturing.

Versatility and Customization Options

Custom metal fabrication is versatile, allowing fabricators to work with various metals to create highly customized products.

Range of Services Offered by Custom Metal Fabricators

Comprehensive Services

| Factors to Consider | Description |

|---|---|

| Expertise | Evaluate the fabricator’s experience and skills in handling projects similar to your requirements. |

| Equipment and Technology | Assess the fabricator’s machinery, tools, and technology to ensure they can meet your project’s needs efficiently and effectively. |

| Quality Assurance | Inquire about the fabricator’s quality control measures and certifications to guarantee the production of high-quality metal products. |

| Lead Times | Consider the fabricator’s ability to meet project deadlines and turnaround times to align with your schedule. |

| Communication | Evaluate the fabricator’s communication and collaboration approach to ensure transparency and alignment throughout the project. |

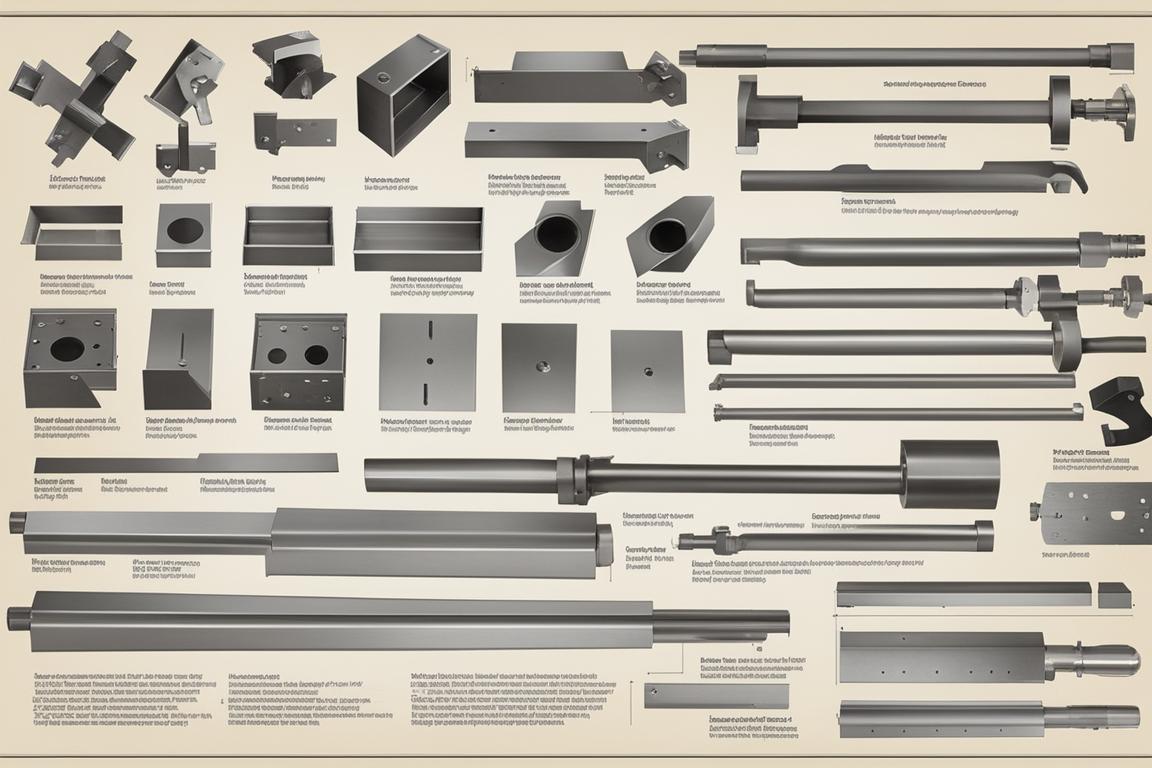

Custom metal fabricators offer a comprehensive suite of services to bring clients’ visions to life, including:

| Services | Description |

|---|---|

| CNC Punching | Precisely punching holes, forms, and other features into metal sheets with high efficiency. |

| Bending | Shaping metal into various forms and angles to create complex geometries and structures. |

| Welding | Joining metal components seamlessly to form cohesive and durable assemblies. |

| Finishing | Applying surface treatments such as painting, powder coating, or plating to enhance appearance. |

Working with Various Metals

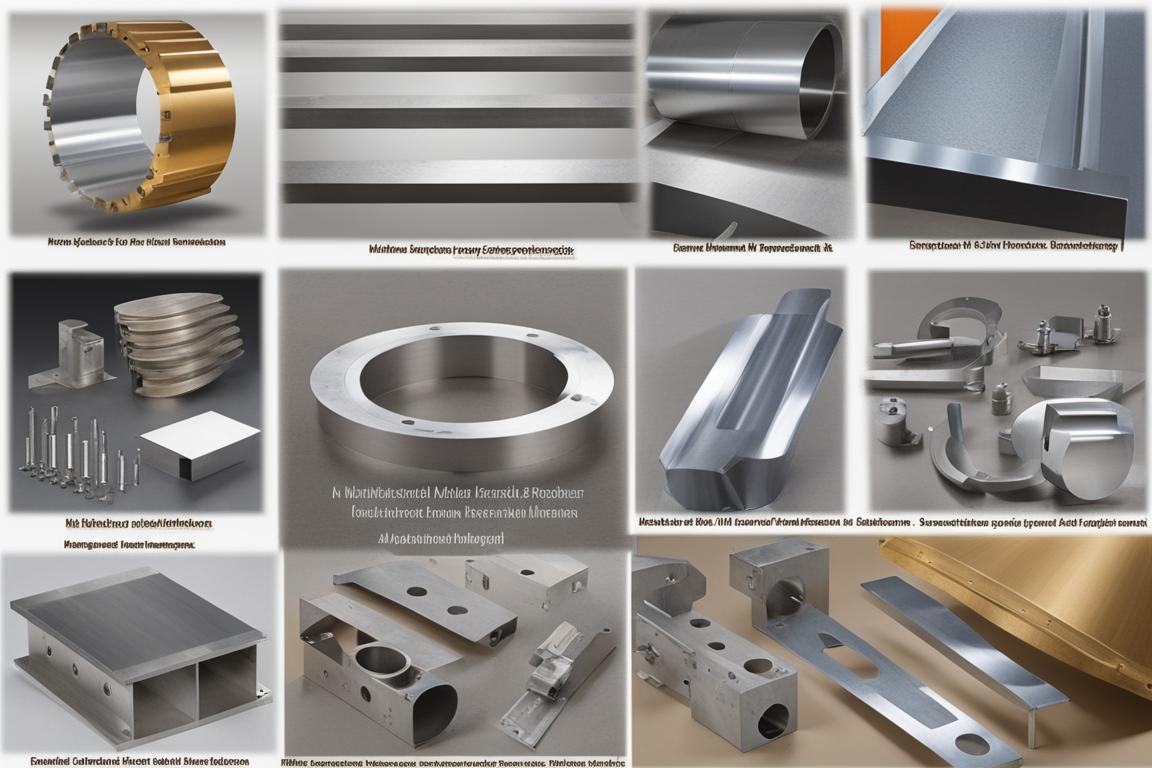

Custom metal fabricators work with a wide array of metals to meet the unique requirements of each material, including:

| Metals | Applications |

|---|---|

| Stainless Steel | Architectural, automotive, and industrial applications. |

| Aluminum | Aerospace components, consumer electronics. |

| Copper | Electrical components, architectural elements, artistic installations. |

| Titanium | Aerospace, medical implants, marine components. |

| Brass | Architectural embellishments, musical instruments, marine hardware. |

Experience and Expertise of Custom Metal Fabricators

Years of Industry Experience

Leading custom metal fabricators bring extensive experience, equipping them with the insight and proficiency needed to tackle various project challenges.

Specialization in Complex Projects

Custom metal fabricators excel in handling complex, intricate projects that demand precision and attention to detail.

Real-Life Examples and Notable Projects

To further demonstrate their expertise, leading custom metal fabricators have successfully completed various notable projects, showcasing their skills in transforming metal into functional and aesthetic products.

Certifications and Unique Approaches

These fabricators often hold industry certifications and adopt unique approaches, ensuring the highest quality and innovation in custom metal fabrication.

Insider Tips

“When choosing a custom metal fabricator, inquire about their experience and expertise in handling projects similar to your requirements. This ensures a higher chance of project success and satisfaction.”

This article provides an overview of custom metal fabrication, including its definition, significance, services offered, metal options, and the expertise of leading fabricators.

Questions & Answers

Who provides custom metal fabrication services?

Precision sheet metal fabrication shops offer these services.

What is custom metal fabrication?

It is the process of shaping and assembling metal parts to meet specific requirements.

How can I find a reliable metal fabrication shop?

Look for shops with a proven track record and positive customer reviews.

Can I afford custom metal fabrication?

While it can be more expensive than mass production, it offers unique solutions.

What makes precision sheet metal fabrication different?

It focuses on high-accuracy and intricate designs for metal components.

How long does custom metal fabrication take?

The timeline varies based on the complexity and scope of the project.