What You’ll Learn About Custom Laser Cutting

By reading this article, you will learn:

– Definition and applications of custom laser cutting.

– The process, benefits, and materials suitable for custom laser cutting.

– Leading service providers and future trends in custom laser cutting.

Custom laser cutting has significantly revolutionized precision sheet metal fabrication, offering a high level of accuracy and intricate detailing. This advanced manufacturing process has become an integral part of various industries, including automotive, aerospace, electronics, and architectural design. It enables the creation of complex and precise components that meet the stringent requirements of modern engineering.

Definition and Applications

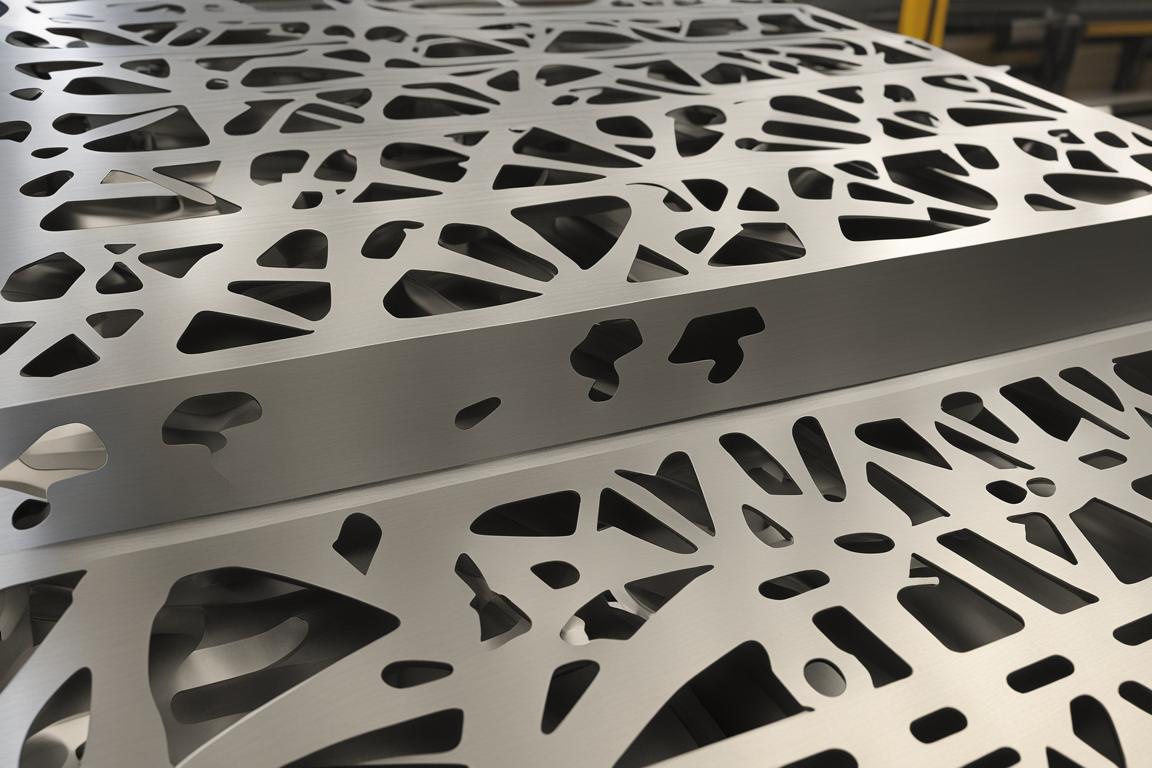

Custom laser cutting is the process of using high-powered lasers to cut, engrave, or mark materials with exceptional precision. The applications of custom laser cutting are diverse, ranging from creating intricate patterns and designs in metal to producing custom parts for machinery and equipment. Its versatility allows for the fabrication of prototypes, one-of-a-kind products, and mass-produced components with equal ease.

Importance in Precision Sheet Metal Fabrication

In the realm of precision sheet metal fabrication, custom laser cutting plays a pivotal role in achieving the exact specifications required for various applications. It offers unparalleled accuracy and repeatability, making it an indispensable tool for creating intricate shapes, holes, and contours in sheet metal. The ability to execute complex designs with minimal material waste has positioned custom laser cutting as a fundamental process in modern manufacturing.

Understanding Custom Laser Cutting

To comprehend the significance of custom laser cutting, it’s essential to delve into the intricacies of the process and the technological advancements that drive it forward.

Laser Cutting Process Overview

Custom laser cutting involves focusing a high-powered laser beam onto the surface of the material to be cut. The intense heat generated by the laser vaporizes, burns, or melts the material along the predetermined cutting line, resulting in a precise and clean cut. This process is computer-controlled, ensuring consistent and accurate cuts with minimal operator intervention.

Use of CAD Designs and CNC Machines

The integration of Computer-Aided Design (CAD) software and Computer Numerical Control (CNC) machines has revolutionized custom laser cutting. CAD designs provide the exact specifications for the cuts, enabling intricate patterns and precise dimensions to be achieved. CNC machines translate these designs into precise movements of the laser, allowing for the creation of highly complex and detailed parts with ease.

Types of Lasers: Fiber lasers and CO2 lasers

Custom laser cutting utilizes different types of lasers, with fiber lasers and CO2 lasers being the most common. Fiber lasers are known for their high energy efficiency and are ideal for cutting metals, while CO2 lasers are versatile and can cut a wide range of materials, including plastics, wood, and rubber. The choice of laser type depends on the material being processed and the specific requirements of the project.

Benefits of Custom Laser Cutting

The advantages of custom laser cutting extend beyond its precision and intricacy, encompassing several key benefits that make it a preferred method in precision sheet metal fabrication.

Advantages in Precision Sheet Metal Fabrication

Custom laser cutting offers unmatched precision, allowing for the creation of intricate designs and complex geometries with exceptional accuracy. This level of precision is critical in industries where the smallest deviation can have significant implications on the functionality and performance of the final product.

Cost-effectiveness and Efficiency

In addition to precision, custom laser cutting is a cost-effective and efficient method of fabrication. It minimizes material waste, reduces the need for secondary operations, and enables rapid prototyping and production. The speed and accuracy of custom laser cutting not only save time but also contribute to overall cost savings in the manufacturing process.

Materials Suitable for Custom Laser Cutting

A pivotal aspect of custom laser cutting is its ability to work with a wide array of materials, allowing for versatility and adaptability in various manufacturing scenarios.

Commonly Used Materials

Custom laser cutting can effectively process materials such as metals (aluminum, steel, brass), plastics, rubber, wood, and composites. This versatility makes it suitable for a diverse range of applications, from creating intricate metal parts to producing detailed signage and artwork.

Compatibility and Quality of Cuts

The process of custom laser cutting ensures compatibility with various materials while maintaining the quality of the cuts. It can handle different thicknesses and densities, providing consistent results across a spectrum of materials and applications.

Customization and Design Capabilities

The flexibility and design capabilities offered by custom laser cutting services are instrumental in meeting the unique requirements of diverse industries and applications.

Flexibility of Custom Laser Cutting Services

Custom laser cutting services offer flexibility in accommodating unique design specifications, enabling the creation of custom parts and components tailored to specific project requirements. This flexibility extends to both prototyping and large-scale production, making it an ideal solution for a wide range of manufacturing needs.

Case Studies and Examples

Numerous case studies and examples demonstrate the extensive customization and design capabilities of custom laser cutting. From intricate architectural metalwork to custom automotive components, the versatility and precision of custom laser cutting have been instrumental in bringing diverse design concepts to life.

Leading Custom Laser Cutting Service Providers

Several industry leaders offer custom laser cutting services, each with its unique strengths and capabilities, providing a comprehensive network of options for manufacturers and designers.

SendCutSend

SendCutSend is a custom laser cutting service that offers fast delivery and affordable pricing. They specialize in aluminum, steel, brass, plastics, titanium, and more. In addition to laser cutting, they provide additional services such as bending, anodizing, and powder coating. Customers can upload CAD designs or use the parts builder for a free instant quote.

Xometry

Xometry offers an online custom laser cutting service for various materials, providing high-quality parts with fast turnaround times and free shipping. They use both fiber lasers and CO2 lasers and can cut through up to 4 inches of metal material. Xometry’s laser cutting service is durable, scalable, and easy to use, with a vetted network of certified suppliers.

Pololu

Pololu offers a custom laser cutting service for creating custom parts out of various materials. They provide step-by-step instructions for ordering and have a wide range of materials and capabilities. Pricing starts at $25, and most orders ship in three business days. They also offer expedited services and local pickup options.

Ponoko

Ponoko is an online custom laser cutting service that offers prototyping and production laser cutting for a wide range of materials. They provide different laser-cutting technologies to ensure high-quality results, with dimensional accuracy, minimum feature size, and maximum material thickness specifications. Ponoko’s software-driven manufacturing service simplifies the process and allows for easy scaling from prototype to production.

Comparison Based on Capabilities, Materials, Turnaround Times, and Additional Services

When choosing a custom laser cutting service provider, it’s crucial to assess their capabilities, materials they work with, turnaround times, and additional services offered. Comparing these factors can help in selecting the most suitable provider for a specific project.

Considerations for Choosing a Custom Laser Cutting Service Provider

Selecting the right custom laser cutting service provider involves evaluating various factors to ensure the quality, reliability, and efficiency of the services offered.

Quality Assurance and Customer Support

Quality assurance and robust customer support are paramount when choosing a custom laser cutting service provider. It’s essential to ensure that the provider maintains high standards of quality and offers responsive customer support throughout the fabrication process.

Pricing and Shipping Options

Transparent pricing and flexible shipping options are key considerations in selecting a custom laser cutting service provider. Understanding the cost structure and shipping logistics helps in planning and budgeting for projects effectively.

Assessing Reliability and Expertise

Assessing the reliability and expertise of a custom laser cutting service provider involves examining their track record, client testimonials, and the capabilities of their manufacturing facilities. This assessment ensures that the chosen provider can consistently deliver high-quality results within the stipulated timelines.

Application Examples of Custom Laser Cutting

The application examples of custom laser cutting are diverse, showcasing its impact across various industries and creative domains.

Real-world Applications in Precision Sheet Metal Fabrication

Custom laser cutting finds extensive use in precision sheet metal fabrication, contributing to the creation of intricate architectural components, aerospace parts, electronic enclosures, and custom automotive elements. Its versatility extends to the production of personalized gifts, signage, and artwork with detailed patterns and designs.

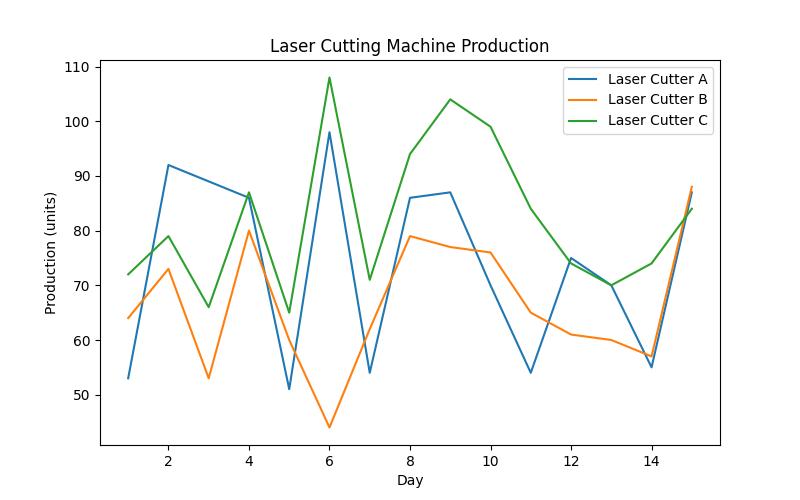

Future Trends and Innovations in Custom Laser Cutting

The future of custom laser cutting is poised for exciting advancements, driven by emerging technologies and innovative developments in laser cutting equipment and software integration.

Emerging Technologies and Innovations

Emerging technologies such as adaptive laser cutting, enhanced automation, and real-time monitoring systems are poised to redefine the landscape of custom laser cutting. These advancements aim to further enhance precision, speed, and material compatibility, opening up new possibilities for intricate designs and complex geometries.

Advancements in Laser Cutting Equipment and Software Integration

The integration of advanced software solutions and cutting-edge laser cutting equipment is set to streamline the custom laser cutting process, enabling seamless design-to-fabrication workflows and enhanced control over intricate cutting patterns. These advancements will empower manufacturers and designers to explore new frontiers in customization and precision.

Conclusion

Custom laser cutting stands as a cornerstone of modern precision sheet metal fabrication, offering unparalleled precision, versatility, and design capabilities. Its significance across diverse industries and applications underscores its pivotal role in bringing intricate designs and complex components to fruition.

Recap of Benefits of Custom Laser Cutting

The benefits of custom laser cutting, including precision, cost-effectiveness, and material versatility, position it as a leading fabrication method in modern manufacturing.

.

Frequently Asked Questions

Q: Who provides custom laser cutting services?

A: Precision sheet metal fabrication companies offer custom laser cutting services.

Q: What is custom laser cutting used for?

A: Custom laser cutting is used to precisely cut sheet metal for various applications.

Q: How does custom laser cutting ensure precision?

A: Custom laser cutting uses advanced technology to produce highly precise cuts on sheet metal.

Q: Can I achieve the same results with other cutting methods?

A: While other methods can be effective, custom laser cutting offers unmatched precision for intricate designs.

Q: What materials can be cut using custom laser cutting?

A: Custom laser cutting can be used to cut various materials such as stainless steel, aluminum, and brass.

Q: How can I request a quote for custom laser cutting?

A: You can easily request a quote for custom laser cutting by contacting a precision sheet metal fabrication company directly.