What You Will Learn about Custom Laser Cutting

By reading this article, you will learn:

1. The types of materials suitable for custom laser cutting, including metals like stainless steel, aluminum, and copper, as well as non-metal materials such as acrylic and wood.

2. The benefits and advantages of custom laser cutting, such as precision and accuracy, speed and efficiency, reduction of material waste, and the ability to create complex and intricate designs.

3. The considerations for choosing a custom laser cutting service provider, including evaluating equipment capabilities, quality control processes, turnaround times, and customer support.

Are you wondering what custom laser cutting is and how it can benefit your industry? Custom laser cutting revolutionizes the fabrication of intricate designs and complex shapes from various materials. This guide provides a comprehensive overview of custom laser cutting, its applications, advantages, and considerations for choosing a custom laser cutting service provider.

Definition and Significance

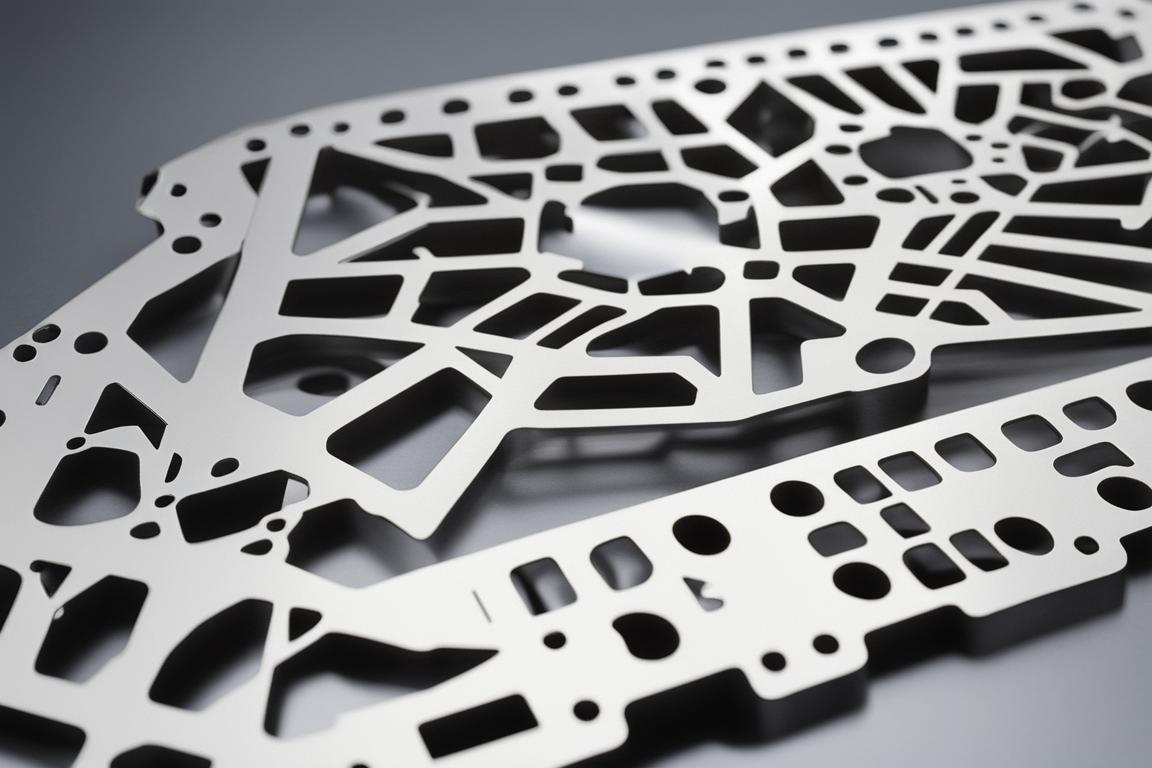

Custom laser cutting uses a high-powered laser to cut, engrave, or mark materials with exceptional precision. It has significant implications across industries, allowing for the production of intricate and customized parts with minimal material waste.

Role in Precision Sheet Metal Fabrication

In precision sheet metal fabrication, custom laser cutting plays a pivotal role in producing complex components with tight tolerances, contributing to the development of innovative products across various industries.

Historical Development

Laser cutting technology’s development can be traced back to the late 1960s, with advancements in laser technology and computer-aided design (CAD) propelling custom laser cutting to the forefront of modern manufacturing.

Understanding Laser Cutting Technology

Laser cutting technology encompasses various systems and processes, each with distinct capabilities and applications.

Types of Laser Cutting Systems

Several types of laser cutting systems include CO2 lasers, fiber lasers, and neodymium (Nd) lasers, each suitable for specific materials and thicknesses.

How Laser Cutting Works

Laser cutting works by directing the output of a high-powered laser, controlled by CNC (Computer Numerical Control), onto the material to be cut, melting, burning, or vaporizing the material to leave a high-quality surface finish.

Advantages Over Traditional Cutting Methods

Compared to traditional cutting methods, custom laser cutting offers exceptional precision, minimal material distortion, and the ability to easily cut complex shapes and patterns.

Limitations and Constraints

While highly versatile, laser cutting has limitations, particularly in cutting certain materials, thicknesses, and reflective surfaces.

Materials Suitable for Custom Laser Cutting

Custom laser cutting is suitable for a wide range of materials, including metals and non-metal substances.

Metals

Stainless Steel

Stainless steel, with its corrosion resistance and durability, is suitable for precise shaping in various industries such as medical devices and architecture.

Aluminum

Aluminum’s lightweight and malleable properties make it ideal for producing lightweight structural components in the aerospace industry.

Copper

Copper’s electrical conductivity and malleability make it suitable for applications such as electrical contacts and heat exchangers.

Non-Metal Materials

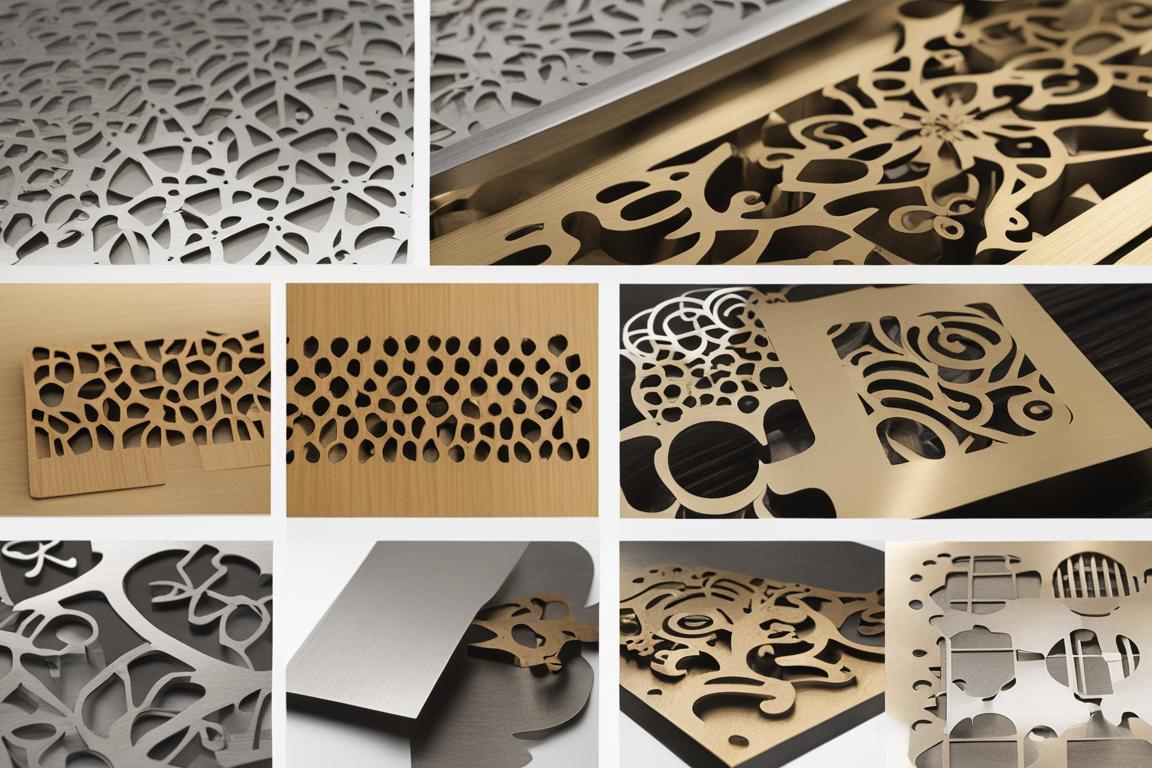

Acrylic

Acrylic, a versatile thermoplastic, is used in architectural models, signage, and decorative elements due to its transparency and ease of laser cutting.

Wood

Wood materials, including plywood and MDF, are frequently laser cut to create intricate patterns for furniture, artwork, and decorative items.

Others

Non-metal materials such as plastics, rubber, and textiles can also be precision-cut using custom laser cutting techniques.

Benefits and Advantages of Custom Laser Cutting

The advantages of custom laser cutting extend across various aspects of manufacturing and design.

| Pros | Cons |

|---|---|

| Unparalleled precision | Limitations in cutting certain materials and thicknesses |

| Remarkably fast and efficient | Potential for high initial equipment and maintenance costs |

| Flexibility for diverse shapes and patterns | Risk of material damage due to the intense heat of the laser |

| Minimization of material waste | Potential for hazardous fumes and airborne contaminants |

| Pros | Cons |

|---|---|

| Unparalleled precision | Limitations in cutting certain materials and thicknesses |

| Remarkably fast and efficient | Potential for high initial equipment and maintenance costs |

| Flexibility for diverse shapes and patterns | Risk of material damage due to the intense heat of the laser |

| Minimization of material waste | Potential for hazardous fumes and airborne contaminants |

Safety Considerations and Regulatory Requirements

When utilizing custom laser cutting, it is essential to adhere to safety considerations and regulatory requirements. This includes proper ventilation to mitigate the risk of hazardous fumes and airborne contaminants. Additionally, operators should receive adequate training to ensure safe and efficient operation of laser cutting equipment.

Real-World Applications and Case Studies

Industry professionals have leveraged custom laser cutting to achieve remarkable results. For instance, in the automotive industry, custom laser cutting has been instrumental in producing intricately designed components that enhance both aesthetics and functionality. Additionally, architectural firms have utilized custom laser cutting to create stunning façades and intricate structural elements, showcasing the versatility and precision of this technology.

Conclusion

Custom laser cutting is a highly efficient and precise manufacturing process with wide-ranging applications across industries. Understanding its technology, suitable materials, advantages, safety considerations, and regulatory requirements is crucial for harnessing its full potential in modern manufacturing and design.

FAQ

Who provides custom laser cutting services?

Precision sheet metal fabrication companies offer custom laser cutting services.

What materials can be used for custom laser cutting?

Custom laser cutting can be done on various materials including steel, aluminum, and copper.

How precise is custom laser cutting?

Custom laser cutting is incredibly precise, with the ability to cut intricate designs with minimal margin for error.

Can custom laser cutting accommodate unique designs?

Yes, custom laser cutting can accommodate unique designs, offering precise and intricate cuts.

How long does custom laser cutting typically take?

The duration for custom laser cutting varies based on the complexity of the design and the material being cut.

What if I need a specific finish on my custom laser cut parts?

Precision sheet metal fabrication companies can offer various finishes, ensuring the custom laser cut parts meet your specific requirements.