What You Will Learn About Laser Cutting in Precision Sheet Metal Fabrication

- Understanding the technology and importance of laser cutting in precision sheet metal fabrication.

- Advantages of laser cutting, including reduced material contamination and enhanced stability.

- Types of lasers used, materials suitable, machine configurations, efficiency factors, design considerations, quality assurance, custom services, and case studies.

Laser cutting, a revolutionary technology in precision sheet metal fabrication, has transformed modern manufacturing processes, offering unparalleled accuracy and efficiency. This comprehensive guide explores the intricacies of laser cutting, its advantages, types of lasers used, suitable materials, machine configurations, and much more.

Understanding Laser Cutting Technology

What is Laser Cutting?

Laser cutting harnesses the power of a high-energy laser beam to vaporize and cut through materials with exceptional precision. The process utilizes laser optics and CNC (computer numerical control) to accurately direct the laser beam, making it an indispensable technology in industrial manufacturing, educational institutions, small businesses, and hobbyist settings.

Applications and Importance in Precision Sheet Metal Fabrication

The significance of laser cutting in precision sheet metal fabrication cannot be overstated. It offers unparalleled precision, making it a go-to technology for creating custom parts, intricate designs, and prototypes across various industries, including aerospace, automotive, and electronics.

Advantages of Laser Cutting

Laser cutting presents several key advantages that set it apart from traditional mechanical cutting methods.

Reduced Material Contamination

Laser cutting significantly reduces the risk of material contamination by producing minimal debris, making it particularly advantageous in industries where material purity is critical, such as in aerospace and medical sectors.

Precision in Cuts

The precision offered by laser cutting is unmatched, allowing for the creation of intricate and complex designs with micron-level accuracy, making it ideal for applications where precision is paramount.

Enhanced Work Holding and Stability

Laser cutting offers superior work holding and stability, ensuring that the material being cut remains secure throughout the process, resulting in high-quality finished products.

| Advantages of Laser Cutting | Types of Lasers Used in Laser Cutting |

|---|---|

| Reduced Material Contamination | Fiber Lasers |

| Precision in Cuts | CO2 Lasers |

| Enhanced Work Holding and Stability | Applications and Suitability in Sheet Metal Fabrication |

Types of Lasers Used in Laser Cutting

Laser cutting utilizes different types of lasers, each with unique characteristics and suitability for specific applications in precision sheet metal fabrication.

Fiber Lasers

Fiber lasers have gained popularity due to their high efficiency and reliability. They are well-suited for cutting thin to medium-thickness materials and are known for their low maintenance requirements, making them an attractive choice for industrial applications.

CO2 Lasers

CO2 lasers are versatile and can effectively cut through a wide range of materials, including metals, plastics, and composites, making them a staple in the manufacturing industry.

Applications and Suitability in Sheet Metal Fabrication

Each type of laser has unique capabilities and is suitable for specific applications within sheet metal fabrication, essential for selecting the most appropriate technology for a given manufacturing requirement.

Materials Suitable for Laser Cutting

Laser cutting is compatible with a diverse range of materials, including metals, plastics, composites, and rubbers, making it a versatile choice for manufacturers working with various substrates.

Metals

Metals, including steel, aluminum, and titanium, are commonly processed using laser cutting due to the technology’s ability to deliver precise cuts without compromising the material’s integrity.

Plastics

Laser cutting is highly effective for processing plastics, offering clean and accurate cuts without the risk of material deformation or warping.

Composites

Composite materials, such as carbon fiber and fiberglass, can be accurately cut using laser technology, making it an invaluable tool for industries reliant on composite structures.

Rubbers

Laser cutting is adept at processing rubber materials, providing clean edges and intricate designs with minimal waste.

Material Characteristics and Considerations

The characteristics of each material, including thickness, conductivity, and reflective properties, influence the laser cutting process, vital for achieving optimal results.

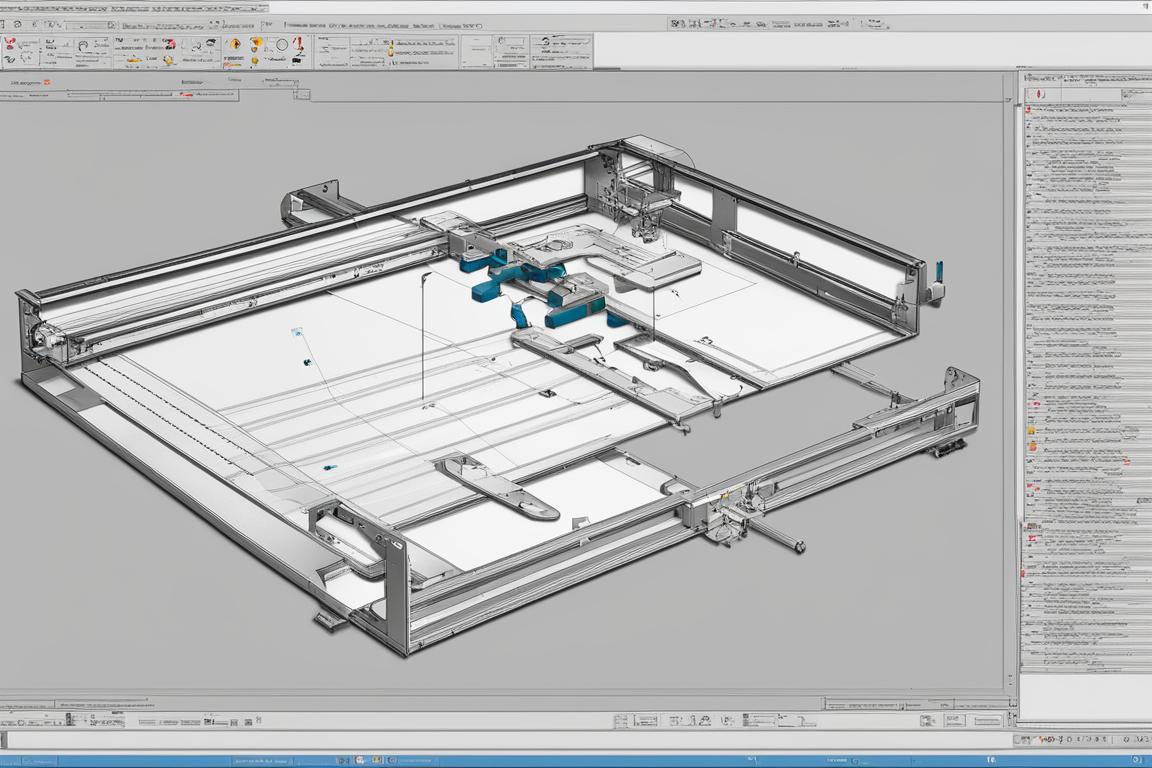

Machine Configurations in Laser Cutting

Various machine configurations are employed in laser cutting, each designed to cater to specific manufacturing requirements.

Overview of Different Machine Configurations

Laser cutting machines come in different configurations, including flatbed, flying optics, and galvo, each offering unique advantages tailored to specific production needs.

Capabilities and Specific Uses of Each Type

Understanding the capabilities and specific uses of each machine configuration is essential for optimizing the laser cutting process and achieving the desired results.

Factors Affecting Laser Cutting Efficiency

Several factors influence the efficiency and effectiveness of laser cutting, ranging from laser power to material thickness and the specific type of cutting process employed.

Influence of Laser Power

Laser power plays a crucial role in determining the cutting speed, depth, and overall efficiency of the process, understanding the relationship between laser power and material properties is key to optimizing cutting operations.

Impact of Material Thickness

Material thickness directly impacts the cutting process. Laser cutting is capable of handling varying material thicknesses, but it’s essential to consider the specific requirements for each application.

Considerations for Different Process Types

Different cutting processes, such as fusion cutting and flame cutting, have unique requirements and considerations, vital for selecting the most suitable process for a given application.

Design Considerations for Laser Cutting

Designing for laser cutting requires a comprehensive understanding of the process and its capabilities, as well as specific design considerations that ensure optimal results.

Importance of Joining Methods

Incorporating suitable joining methods is essential for ensuring the structural integrity of laser-cut components, critical for successful design implementation.

Design Techniques and Best Practices

Implementing design techniques, such as minimizing sharp corners and optimizing part nesting, enhances the manufacturability of laser-cut components, ensuring efficient production and high-quality output.

Software and Cutting Techniques in Precision Sheet Metal Fabrication

The software and cutting techniques utilized in laser cutting play a pivotal role in achieving precision and efficiency in precision sheet metal fabrication.

Design Software Utilized in Laser Cutting

Advanced design software, such as CAD and CAM tools, are integral for creating precise designs and generating cutting paths for laser cutting machines.

Cutting Techniques and Methods

Various cutting techniques, including vector cutting, raster engraving, and etching, offer flexibility in achieving a wide range of design and finishing effects in precision sheet metal work.

Quality Assurance and Tolerances in Laser Cutting

Maintaining stringent quality assurance standards and tolerances is paramount in precision sheet metal fabrication to ensure the highest level of accuracy and consistency in the finished products.

Critical Importance of Quality Assurance

Implementing robust quality assurance measures, including material inspection and process validation, is essential for upholding the quality standards in laser cutting.

Understanding and Maintaining Guaranteed Tolerances

Understanding the guaranteed tolerances for laser cutting and ensuring compliance with these specifications is essential for meeting the exacting requirements of precision sheet metal work.

Custom Laser Cutting Services

The availability of online custom laser cutting services has democratized access to high-quality laser cutting capabilities, offering a range of benefits for manufacturers and designers.

Overview of Online Custom Laser Cutting Services

Online custom laser cutting services provide easy access to high-quality laser cutting for a wide range of materials and applications.

Capabilities, Material Options, and Turnaround Times

These services offer a wide array of material options, scalable production capabilities, and fast turnaround times, making them an attractive option for both prototyping and production needs.

Software-Driven Manufacturing Services

Software-driven manufacturing services are transforming the landscape of precision sheet metal fabrication, streamlining the laser cutting process and enabling seamless scalability.

Streamlining Laser Cutting Processes with Software

The integration of software solutions in laser cutting streamlines the entire process, from design to production, optimizing efficiency and reducing lead times.

Scaling from Prototype to Production Using Software

Software-driven manufacturing services facilitate the seamless transition from prototype development to full-scale production, offering a cohesive and efficient manufacturing ecosystem.

Additional Manufacturing Services Related to Laser Cutting

In addition to laser cutting, a range of complementary manufacturing services, such as 3D printing, plastic injection molding, CNC milling, and PCB fabrication and assembly, contribute to a comprehensive manufacturing ecosystem.

3D Printing and Its Applications

3D printing technologies complement laser cutting, offering rapid prototyping and intricate design capabilities for a wide range of applications.

Plastic Injection Molding

Plastic injection molding provides high-volume production capabilities for plastic components, complementing the capabilities of laser cutting in sheet metal fabrication.

CNC Milling

CNC milling services offer precise machining solutions for a variety of materials, complementing the capabilities of laser cutting in sheet metal fabrication.

PCB Fabrication and Assembly

The fabrication and assembly of printed circuit boards (PCBs) align with the precision and intricacy offered by laser cutting.

Case Studies and Examples in Laser Cutting

Real-world case studies and examples demonstrate the diverse applications and success stories in precision sheet metal fabrication enabled by laser cutting technologies.

Real-world Applications of Laser Cutting

Case studies highlight the use of laser cutting in industries such as aerospace, automotive, and consumer electronics, showcasing its pivotal role in achieving high-quality, precision components.

Success Stories in Precision Sheet Metal Fabrication

Examples of successful projects and products manufactured using laser cutting underscore its significance in enabling innovation and excellence in precision sheet metal work.

Resources for Further Learning

For those seeking to delve deeper into the world of laser cutting and precision sheet metal fabrication, a wealth of resources and communities provide avenues for ongoing education and professional development.

Industry Publications and Journals

Industry-specific publications and journals offer in-depth insights into the latest developments, best practices, and case studies in laser cutting and precision sheet metal work.

Relevant Organizations and Associations

Joining relevant organizations and associations dedicated to precision sheet metal fabrication and laser cutting provides access to networking opportunities and valuable industry resources.

Online Communities and Forums

Engaging with online communities and forums focused on laser cutting and precision sheet metal work fosters knowledge sharing and collaboration among industry professionals and enthusiasts.

Conclusion

Laser cutting technology has revolutionized precision sheet metal fabrication, offering unparalleled accuracy, flexibility, and productivity. By gaining a comprehensive understanding of this technology and its applications within the manufacturing industry, businesses and designers can harness its capabilities to foster innovation and achieve excellence.

By utilizing the knowledge and insights provided in this guide, individuals and organizations can confidently explore the realm of laser cutting, unlocking its potential to bring their creative and manufacturing visions to life. If you have any questions or require further assistance, please do not hesitate to contact us.

Questions & Answers

Question: Who uses laser cutting in precision sheet metal fabrication?

Answer: Precision sheet metal fabricators use laser cutting for its accuracy and speed.

Question: What materials can be cut using laser cutting in sheet metal fabrication?

Answer: Laser cutting can be used to cut materials such as stainless steel, aluminum, and brass.

Question: How does laser cutting contribute to precision in sheet metal fabrication?

Answer: Laser cutting creates precise and clean cuts, allowing for intricate designs and tight tolerances.

Question: What if I need a variety of shapes and sizes in my sheet metal project?

Answer: Laser cutting is versatile and can produce a wide range of shapes and sizes to meet your project needs.

Question: How can laser cutting in sheet metal fabrication be cost-effective?

Answer: Laser cutting is cost-effective due to its high speed and efficiency in producing accurate cuts, reducing material waste.

Question: What are the limitations of laser cutting in precision sheet metal fabrication?

Answer: While laser cutting is highly precise, it may not be suitable for very thick or reflective materials.