Custom Sheet Metal Fabrication

When it comes to shaping a successful product, the initial step starts at Atlas Manufacturing. We understand the importance of producing high-quality welded metal assemblies and components. Thus, we ensure our job is completed with precision and excellence.

Our quick turnaround on your order guarantees continued operation and project completion in a timely fashion. Our fabricated metal parts are welded, fastened, and assembled uniquely to fit your strict requirements.

High-quality Welded Metal Assemblies for Specific Applications

We are an industry leader in the production of welded assemblies for custom products, providing one-stop shopping for shaping the metal behind your brand. Our goal is to make your supply chain experience as efficient, effective, and seamless as possible. By delivering the largest shippable compilation of components to our OEM, we ensure the superiority of your products and processes and aim to lower inventory transactions and carrying costs for your production process.

Furthermore, we offer flexibility to meet our customer's needs in various ways. We can provide ESD grounding, thermal insulation, weldment leak verification, or consigned customer components built into the welded assemblies. Simply put, we are an extension of the original equipment manufacturer (OEM) production.

Precision & Excellence in Our Welding Services

Welded assemblies are a type of metal construction that involves the fusion of multiple metal materials, such as stainless steel, to create a larger, more complex structure. This technique can design and create almost any shape you want for your unique application. We use welding assembly to create anything from small or large metal parts, such as brackets and tubes.

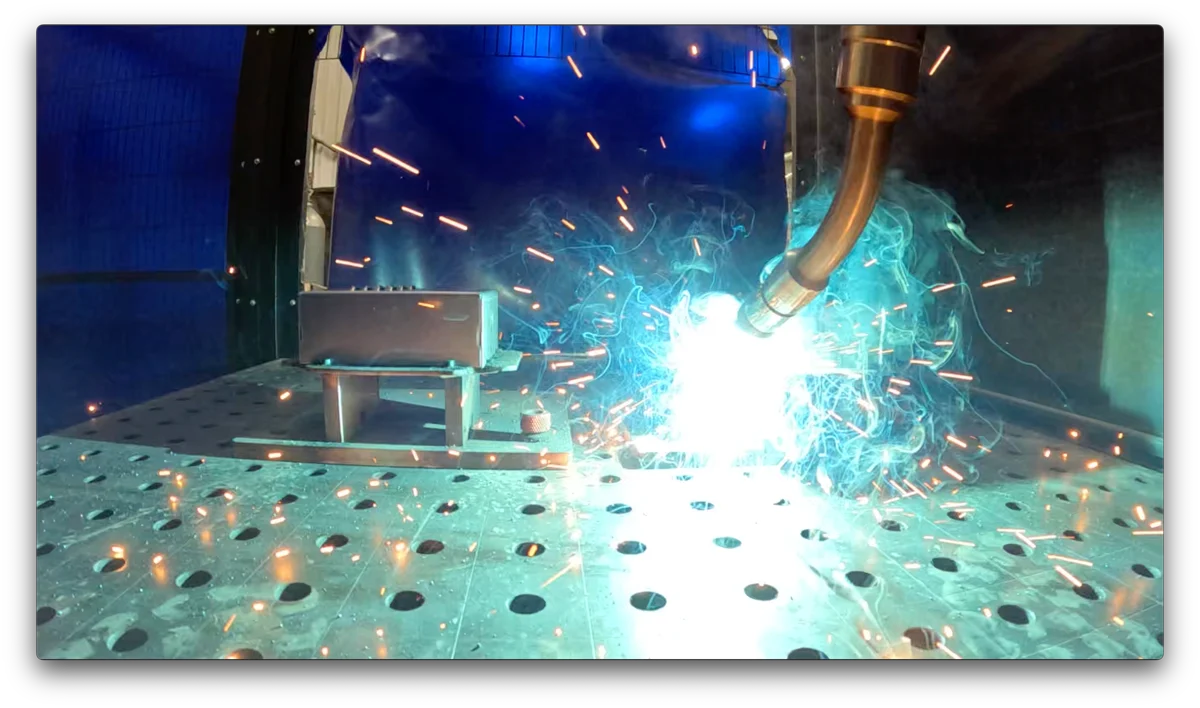

The process of creating welded assemblies is straightforward. However, implementing it requires the latest tools and techniques to complete the job perfectly. For instance, using advanced welding tactics with specialized weld tables and fixtures.

We deliver precision and excellence in its welded assemblies using the most advanced tools available. These include:

- MIG (Metal Inert Gas) welding: Gas Metal Arc Welding (GMAW) or MIG welding uses a continuous wire to form an electric arc. The heat from this arc melts the wire while creating a weld pool of filler material that joins the two metals.

- Robotic welding: As the name implies, this technique uses robots or automated positioning and welding. These robots perform repetitive tasks while components are held in high tolerance fixtures.

- TIG (Tungsten Inert Gas) welding: Also called gas tungsten arc welding (GTAW), TIG welding relies on an inert gas, such as helium or argon, to shield the weld area from atmospheric gasses while fusing the components together. A non-consumable tungsten electrode and the workpiece generate heat for welding.

Various Joining Process for Your Specific Needs

As a lean manufacturing facility, we are flexible and adapt our workspace to meet the needs of our customers. Our capabilities include several welding assembly services, such as:

- Adhesive bonding: This uses a nonmetallic substance to join closely spaced metal parts through surface attachment.

- Insulation: We also can manufacture stainless steel hot-side components using rigid rock wool insulation.

- Mechanical assembly: Mechanical assemblies connect two or more metal parts using fasteners or studs, such as screws, rivets, bolts, or nut and bolt combinations.

- Prototype development: With advanced CAD software, we can develop, prototype, and implement an entire welding process based on your tolerances.

- Resistance spot welding: Utilizing pressure combined with electrical discharge, like materials are fused together.

Industries Served

Our company serves diverse industries through its advanced production facility and highly skilled team, including:

- Commerical

- Communication

- Food prep and storage

- High performance computing (HPC)

- Industrial

- Medical and dental

- And more

Why Choose Us for Welded Assembly

We understand the need to provide our customers with new and improved value-added services. Thus, we strive to produce a clean, robust assembly for any application. Our products allow you to focus on your core competencies with the confidence that our welded assemblies can seamlessly integrate into your processes.

Moreover, sourcing your metal parts with us eliminates the hassle of dealing with multiple suppliers. As your trusted partner, we strive to help reduce your overall production costs.

Here's why you should trust us:

Commitment to Quality

Our team is committed to providing exceptional quality, value, and service from design to final production.

Rush Services

Unlike manual welding, we have automated processes. Thus, we can rush your orders without compromising quality.

On-time Delivery

Word of mouth is critical to our business, and so is your success. Thus, we always meet our promise to deliver your orders on time.

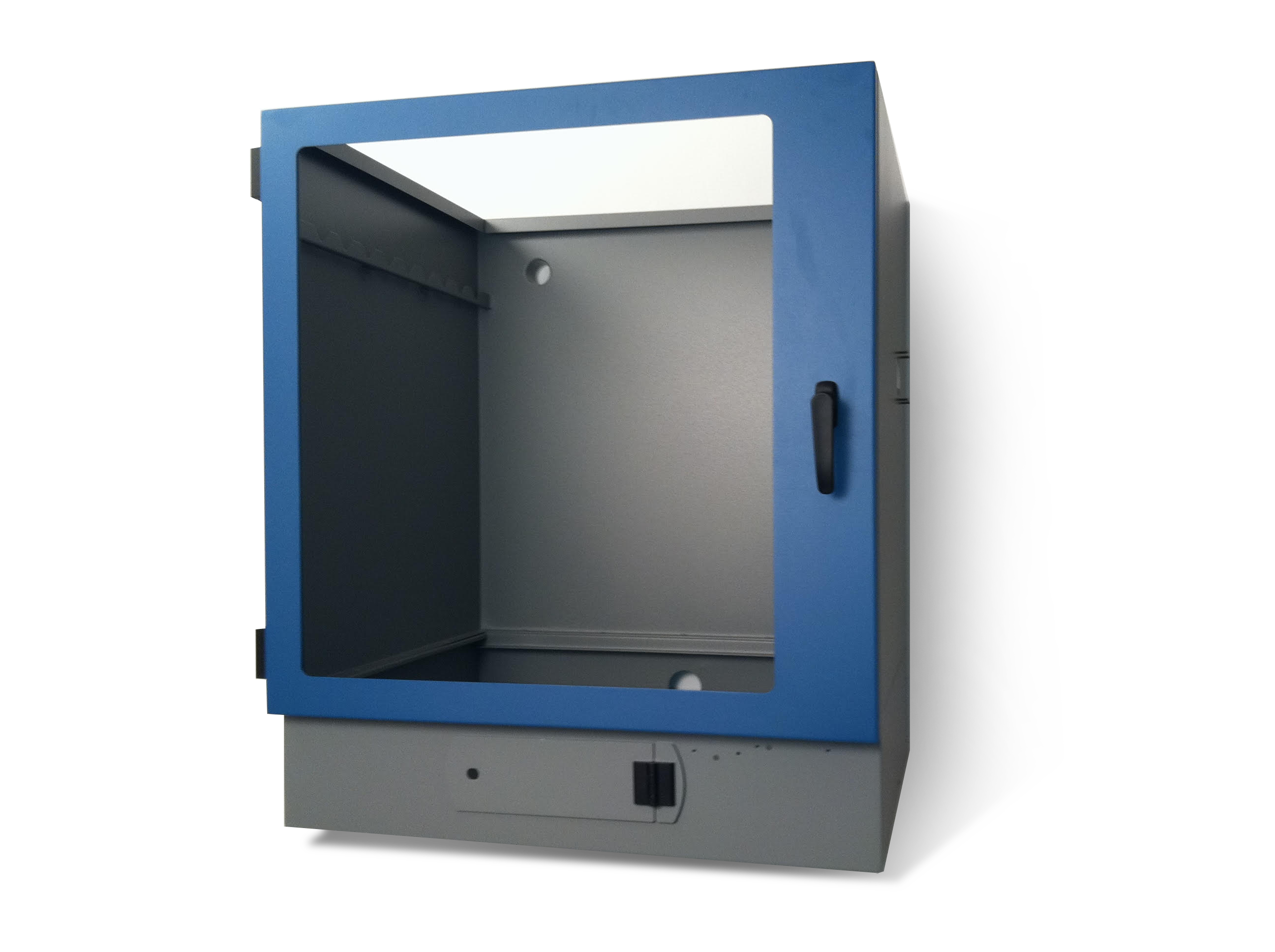

Forensic Evidence Cabinet

At Atlas Manufacturing, our expertise in welded assemblies goes beyond traditional applications. A testament to our welding prowess is the intricately designed crime scene evidence cabinet. This assembly is not just a testament to our precision in metalwork but also showcases our ability to fuse functionality with innovation. The cabinet's lower section is meticulously welded to house a mechanism that introduces vaporized cyanoacrylate, commonly known as superglue. This vapor, when in contact with evidence suspended within the cabinet, reveals latent fingerprints. Such a complex structure demands the highest standards of welding, ensuring the cabinet is both robust and precise in its function. It's not just a cabinet; it's a symbol of our commitment to excellence in welded assemblies.

Get Top-notch Welded Assemblies Today

To learn more about our fabricated metal services or order welded assemblies, don't hesitate to contact us today!