When Atlas Manufacturing made a shift from turret punch presses to Trumpf technology, the change created a revolution and evolution in punching. Knowledge of Trumpf punching methodology expanded rapidly to off-line advance tool set-up reduction, Wilson wheel technology, extrude and tap capability, and a plethora of form features and benefits never before realized with turret punches. A whole new world of punching techniques and capabilities were opened up in front of the Atlas engineers. As business grew, so did the demand for more punching and the purchase of additional Trumpf 5000 punches.

The Trumpf 5000 punch has the speed of a bullet train and the precision of a surgeon. With the automation involving a tower to feed material, automatic sorting and scrap skeleton removal plus full rail automatic tool changing, this is the most flexible high speed punching machine available in the market today. Over the span of 16 years, Atlas has continually added more machines and tooling to support their complex precision fabrication demands.

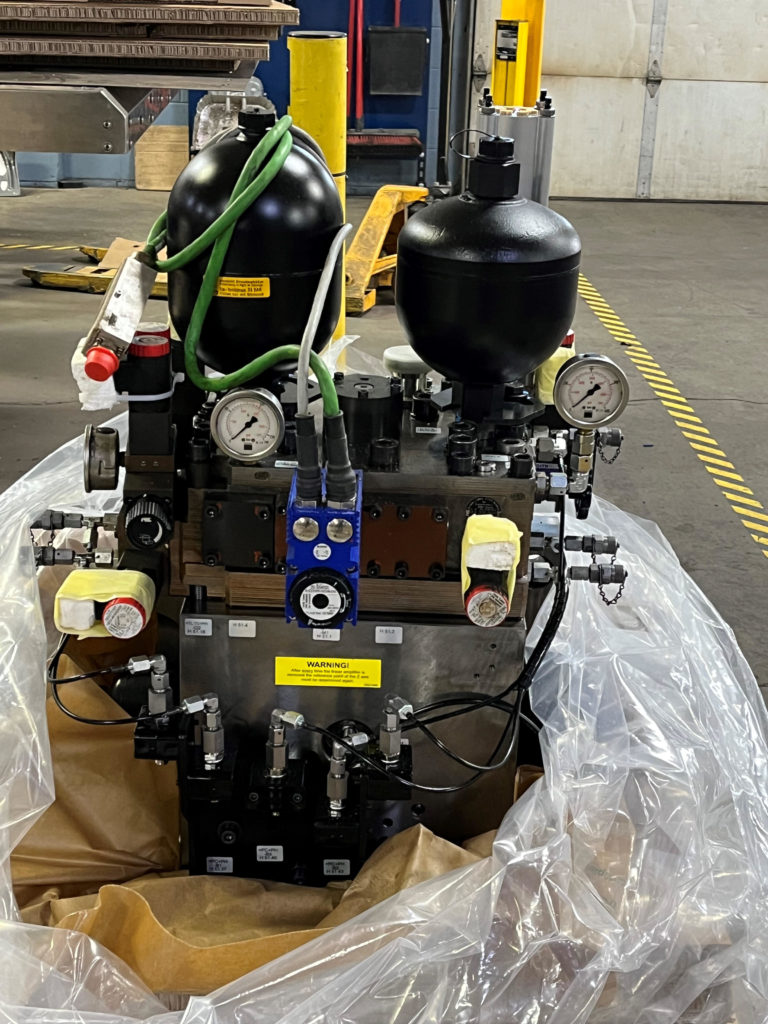

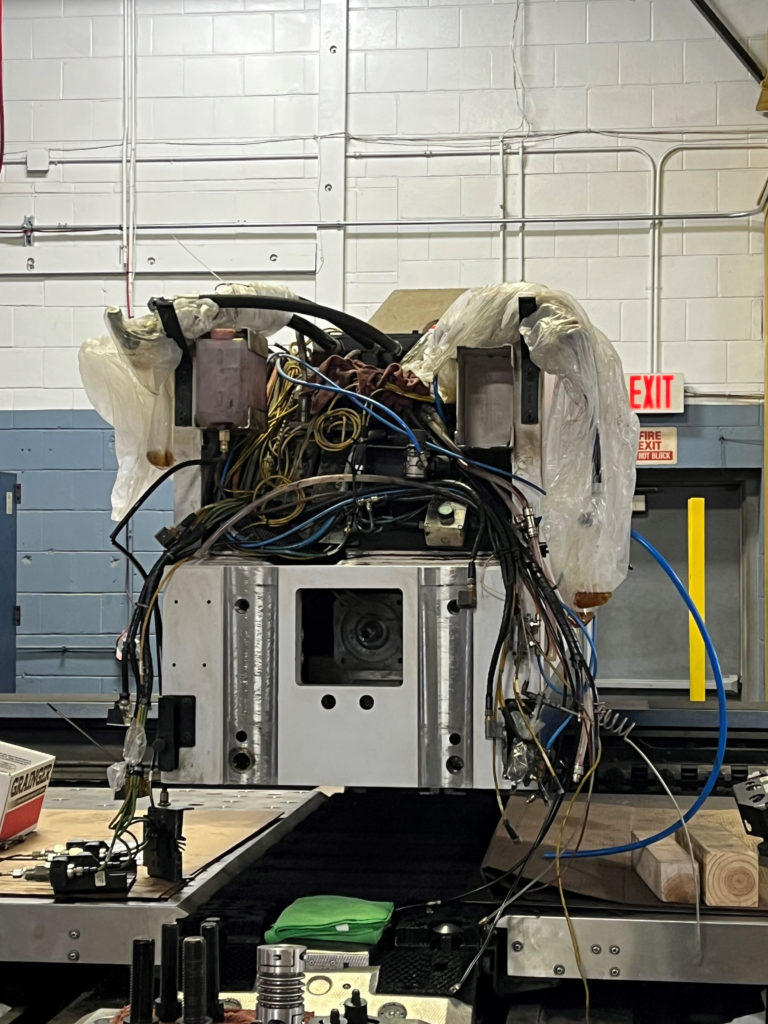

These machines are worked hard, day after day, year after year. As with most mechanical systems, eventually parts wear, break, and require service. Our 2009 Trumpf 5000 was no exception. When the punch stopped, Trumpf service was called in to analyze the situation. The analysis of the problem revealed a catastrophic fault inside the punching head as a result of a keyway failure. Faced with the uncertain aspect of replace or repair, the decision was made to remove the punch head unit and ship it to Germany for inspection and rebuild.

Here is where the story gets interesting. Sending a major machine component (really the heart and lungs of the machine) to a location in Europe for repair seemed preposterous to everyone at first. Our steadfast belief in the technology and the Trumpf organization allowed us the leap of faith to ship the punch head to Germany. With multiple 5000 machines, we were able to afford the time to have the machine down for an extended period of time.

Shipment notification came! The punch head had been repaired was en-route back to it’s home in Minneapolis. Of course fear and doubt about the receipt of the machine part started to creep in. Will it arrive intact? Will Trumpf be able to reconstruct assembly? Once installed, will it actually run? After a suspenseful two days, the machine was up and running like new. A very successful return after an extended trip to Europe and the machine is back in production.