Are you looking to gain a comprehensive understanding of precision sheet metal fabrication? Look no further. This complete handbook will provide you with detailed insights into the processes, materials, and applications associated with precision sheet metal fabrication.

What You Will Learn About Precision Sheet Metal Fabrication

- Definition, processes, and materials used in precision sheet metal fabrication.

- Tools, equipment, quality control, and industry applications.

- Advantages, challenges, innovations, and future trends in precision sheet metal fabrication.

Definition and Importance of Precision Sheet Metal Fabrication

Precision sheet metal fabrication is a specialized manufacturing process used to create highly accurate, detailed metal components for various industrial applications. These components are vital in industries where accuracy and reliability are paramount, such as aerospace, automotive, electronics, and construction.

Historical Evolution and Technological Advancements

The origins of precision sheet metal fabrication can be traced back to ancient metalworking techniques. However, technological advancements, such as the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM), have revolutionized the precision and efficiency of metal fabrication processes.

Importance in Various Industries

Precision sheet metal fabrication plays a crucial role in diverse industries, including aerospace, automotive, electronics, and architectural sectors, due to its ability to produce complex, high-quality metal components.

The Process of Precision Sheet Metal Fabrication

The process of precision sheet metal fabrication involves several key stages, each contributing to the creation of accurate and intricate metal components.

Material Selection and Properties

The first step in precision sheet metal fabrication is the careful selection of materials based on the mechanical properties required for the final product. Common materials include aluminum, stainless steel, copper, and titanium, each chosen for its specific characteristics and applications.

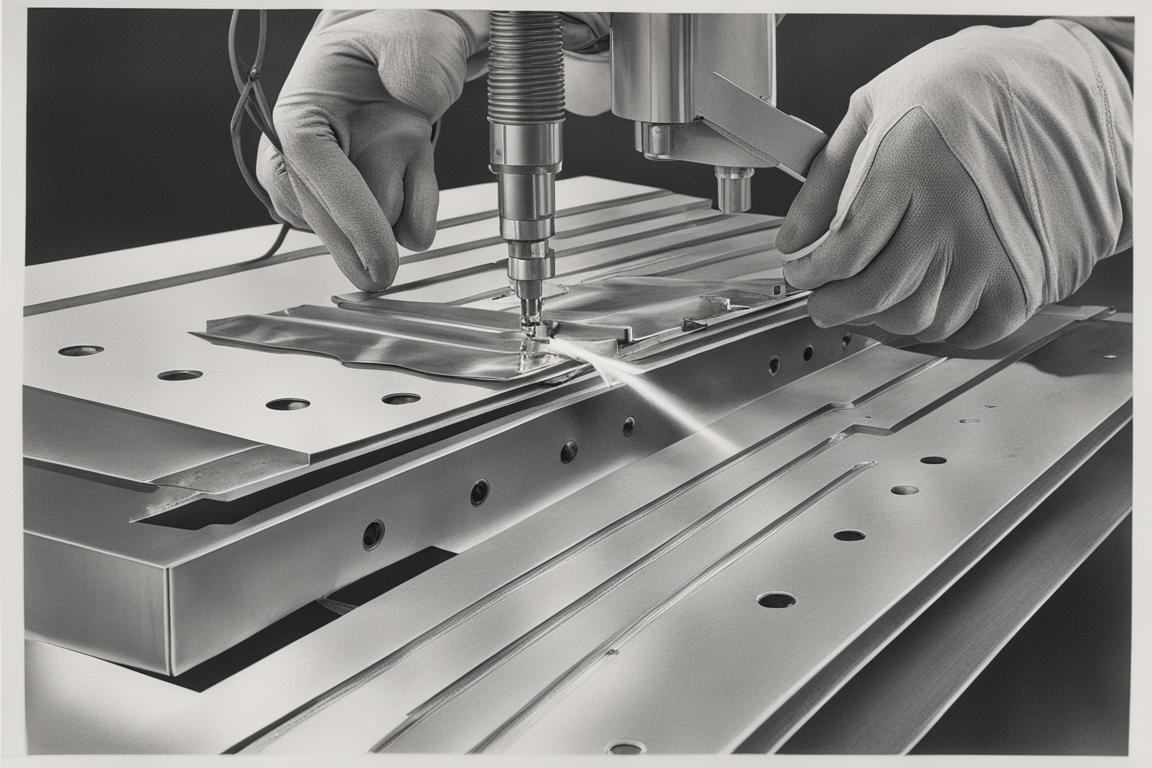

Cutting Techniques and Technologies

Cutting is a fundamental process in precision sheet metal fabrication. Advanced cutting technologies such as laser cutting and CNC punching machines enable the precise shaping of metal sheets according to design specifications.

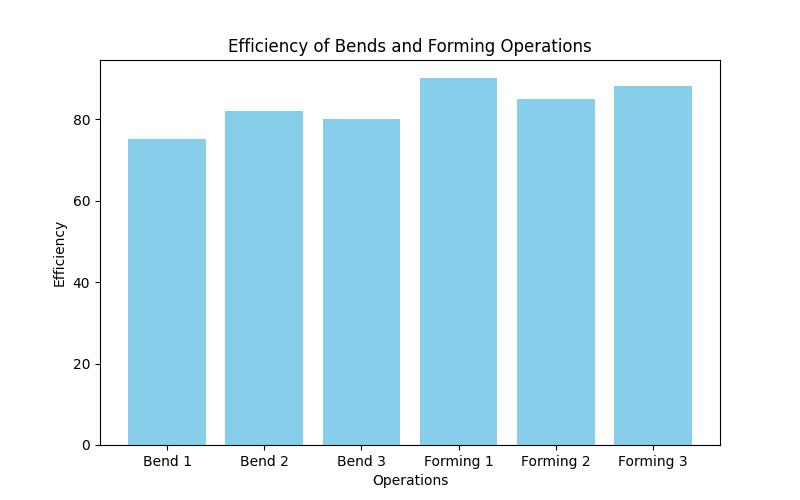

Bending, Forming, and Press Brake Operations

Bending and forming metal sheets into desired shapes and angles are critical steps in the fabrication process. Press brake operations are used to achieve accurate bends and creases in the metal, ensuring the final product meets precise dimensional requirements.

Joining and Assembly Methods

The assembly of individual metal components is achieved through various joining methods, including welding, riveting, and fastening. Each method requires precision to ensure the structural integrity and functionality of the final product.

Surface Finishing and Coating Processes

Surface finishing and coating are essential for enhancing the appearance, durability, and corrosion resistance of precision sheet metal components. Processes such as powder coating and anodizing provide protective and decorative finishes.

Materials Used in Precision Sheet Metal Fabrication

The choice of materials significantly impacts the performance and characteristics of the final products.

Aluminum: Properties and Applications

| Advantages | Challenges |

|---|---|

| High accuracy and precision | Costly equipment and tooling |

| Versatility in material selection | Skilled labor shortage |

| Wide range of applications | Quality control and inspection |

| Efficient production of complex components | Environmental impact and waste management |

Aluminum is a lightweight and corrosion-resistant material widely used in precision sheet metal fabrication for applications requiring high strength-to-weight ratios, such as in aerospace and automotive industries.

Stainless Steel: Versatility and Characteristics

Stainless steel is valued for its durability, resistance to corrosion, and aesthetic appeal. It is commonly used in precision sheet metal fabrication for applications in the food industry, architecture, and medical equipment.

Copper: Applications and Advantages

Copper’s excellent electrical and thermal conductivity make it suitable for precision sheet metal fabrication in electronic components, heat exchangers, and architectural elements.

In conclusion, precision sheet metal fabrication is a critical process with wide-ranging applications across various industries. Its evolution, technological advancements, and the materials involved make it an essential part of modern manufacturing. By understanding the intricacies of precision sheet metal fabrication, industries can continue to produce high-quality, reliable products.

Q & A

Q. Who offers precision sheet metal fabrication services?

A. Precision sheet metal fabrication services are offered by specialized manufacturing companies.

Q. What is precision sheet metal fabrication?

A. Precision sheet metal fabrication is the process of shaping and assembling sheet metal with high accuracy and tight tolerances.

Q. How is precision sheet metal fabrication different from regular fabrication?

A. Precision sheet metal fabrication focuses on achieving extremely tight tolerances and high accuracy in the shaping and assembly of sheet metal.

Q. What if I have specific design requirements?

A. If you have specific design requirements, precision sheet metal fabrication can be tailored to meet your exact specifications.

Q. How can I ensure the quality of precision sheet metal fabrication?

A. You can ensure the quality of precision sheet metal fabrication by working with experienced and certified fabrication companies.

Q. What if I have concerns about cost-effectiveness?

A. While precision sheet metal fabrication may have higher initial costs, its accuracy and quality often lead to long-term cost savings and efficiency gains.