What You’ll Learn About Metal Fabricators

By reading this article, you will learn:

– The definition and role of metal fabricators in precision sheet metal fabrication

– The materials, equipment, and technologies used in the metal fabrication process

– The importance of quality control, compliance, and industry applications for metal fabricators

What Are Metal Fabricators and Their Role in Precision Sheet Metal Fabrication?

Metal fabricators, also known as sheet metal fabricators, are highly skilled professionals who play a crucial role in the precision sheet metal fabrication industry. They are responsible for transforming raw materials into high-quality, meticulously designed metal parts and products. Their expertise lies in shaping, cutting, and assembling various metal components to exact specifications, ensuring the highest standards of precision and quality in the final output.

Understanding Precision Sheet Metal Fabrication Process

Design and Prototyping

The precision sheet metal fabrication process begins with meticulous design and prototyping. Metal fabricators work closely with engineers and designers to interpret blueprints, create detailed CAD models, and develop prototypes that meet the client’s exact requirements.

Cutting Techniques in Metal Fabrication

Metal fabricators utilize a variety of cutting techniques to shape metal sheets, including laser cutting, plasma cutting, and water jet cutting. These methods allow for precise and intricate cuts, ensuring that the final product meets the most demanding specifications.

Forming and Bending Processes

Forming and bending are crucial stages in metal fabrication, requiring exceptional skill and precision. Metal fabricators use specialized equipment such as press brakes and rollers to accurately shape metal sheets and achieve the desired configurations.

Assembling and Finishing

Assembling the fabricated metal components and applying finishing touches are essential steps in the process. Metal fabricators meticulously join the parts using welding, fasteners, or adhesives, followed by surface treatments such as painting, powder coating, or plating to enhance durability and aesthetics.

Metal Fabricators’ Involvement in Each Stage

Throughout every stage of precision sheet metal fabrication, metal fabricators are deeply involved, ensuring that each step is executed with the utmost precision and attention to detail. Their expertise and craftsmanship are instrumental in delivering high-quality, custom metal products.

Materials in Precision Sheet Metal Fabrication

Common Metals and Alloys Used

Metal fabricators work with a wide range of metals and alloys, including stainless steel, aluminum, copper, brass, and titanium. Each material offers unique properties and advantages, allowing metal fabricators to cater to diverse industry needs.

Material Selection Considerations by Metal Fabricators

When selecting materials for a project, metal fabricators carefully consider factors such as strength, corrosion resistance, conductivity, and appearance. Their expertise in material selection ensures that the fabricated components meet the required performance standards and aesthetic criteria.

In the field of precision sheet metal fabrication, the role of metal fabricators cannot be overstated. Their craftsmanship and attention to detail are critical in delivering top-quality, custom metal products to various industries.

Now, let’s delve into the advanced equipment and technologies that drive the precision and efficiency of metal fabrication processes.

Advanced Equipment and Technologies for Metal Fabrication

CNC Laser Cutting and its Role

CNC (Computer Numerical Control) laser cutting is a pivotal technology in precision sheet metal fabrication. Metal fabricators use high-powered lasers guided by CNC systems to make precise cuts on metal sheets, ensuring exceptional accuracy and repeatability.

CNC Punching and Metal Fabrication

CNC punching machines enable metal fabricators to perforate, form, and punch features into metal sheets with remarkable speed and accuracy. This technology enhances the efficiency and versatility of metal fabrication processes.

Robotic Welding Systems

Robotic welding systems have revolutionized the welding stage of metal fabrication. Metal fabricators leverage advanced robotic arms equipped with welding tools to achieve consistent and high-quality welds, significantly improving productivity and precision.

Impact on Precision and Efficiency

The integration of advanced equipment and technologies elevates the precision and efficiency of metal fabrication, empowering metal fabricators to meet intricate design requirements and tight tolerances while optimizing production workflows.

The use of cutting-edge equipment and technologies underscores the commitment of metal fabricators to delivering exceptional quality and precision in every fabricated component.

Quality control, compliance, and inspection are paramount in ensuring that fabricated metal products meet industry standards and client expectations.

Quality Control, Compliance, and Inspection

Importance of Quality Control Measures

Quality control measures are integral to the metal fabrication process, encompassing stringent inspections and testing protocols to verify the precision, integrity, and performance of fabricated components.

Adherence to Industry Standards and Regulations

Metal fabricators adhere to rigorous industry standards and regulations, such as ISO 9001 and AS9100, to uphold the highest levels of quality, safety, and compliance in their fabrication processes.

Metal Fabricators’ Role in Inspections and Testing

Metal fabricators conduct meticulous inspections and testing, utilizing advanced metrology equipment and non-destructive testing methods to validate the dimensional accuracy, material properties, and structural integrity of fabricated metal components.

The dedication of metal fabricators to quality control and compliance ensures that their fabricated products consistently meet the most stringent industry requirements.

Customization, prototyping, and collaboration are central to the specialized services offered by metal fabricators.

Customization, Prototyping, and Collaboration

Accommodating Custom Design Requirements

Metal fabricators excel in accommodating custom design requirements, leveraging their expertise to translate unique concepts into precision-engineered metal products tailored to the specific needs of clients across diverse industries.

Prototyping Process and Collaboration with Engineers

The prototyping process involves close collaboration between metal fabricators and engineers, enabling iterative refinement of designs and validation of manufacturability to achieve optimal outcomes in custom metal fabrication projects.

Precision and Accuracy in Custom Fabrication

Precision and accuracy are the hallmark of custom metal fabrication, and metal fabricators are committed to delivering bespoke solutions that align with clients’ exact specifications, performance standards, and aesthetic preferences.

Metal fabricators’ proficiency in customization and collaboration underscores their pivotal role in fulfilling the specialized requirements of diverse industries.

The applications of precision sheet metal fabrication are extensive, spanning critical sectors such as aerospace, automotive, electronics, and medical device manufacturing.

Industry Applications and Case Studies

Aerospace and Metal Fabricators

Metal fabricators play a vital role in aerospace applications, fabricating components that meet stringent performance and safety standards, contributing to the advancement of aviation and space exploration.

Automotive and Metal Fabrication

In the automotive industry, metal fabricators supply precision-engineered parts and assemblies, supporting the development of innovative vehicles and ensuring the reliability and efficiency of automotive systems.

Electronics Industry and Metal Fabricators

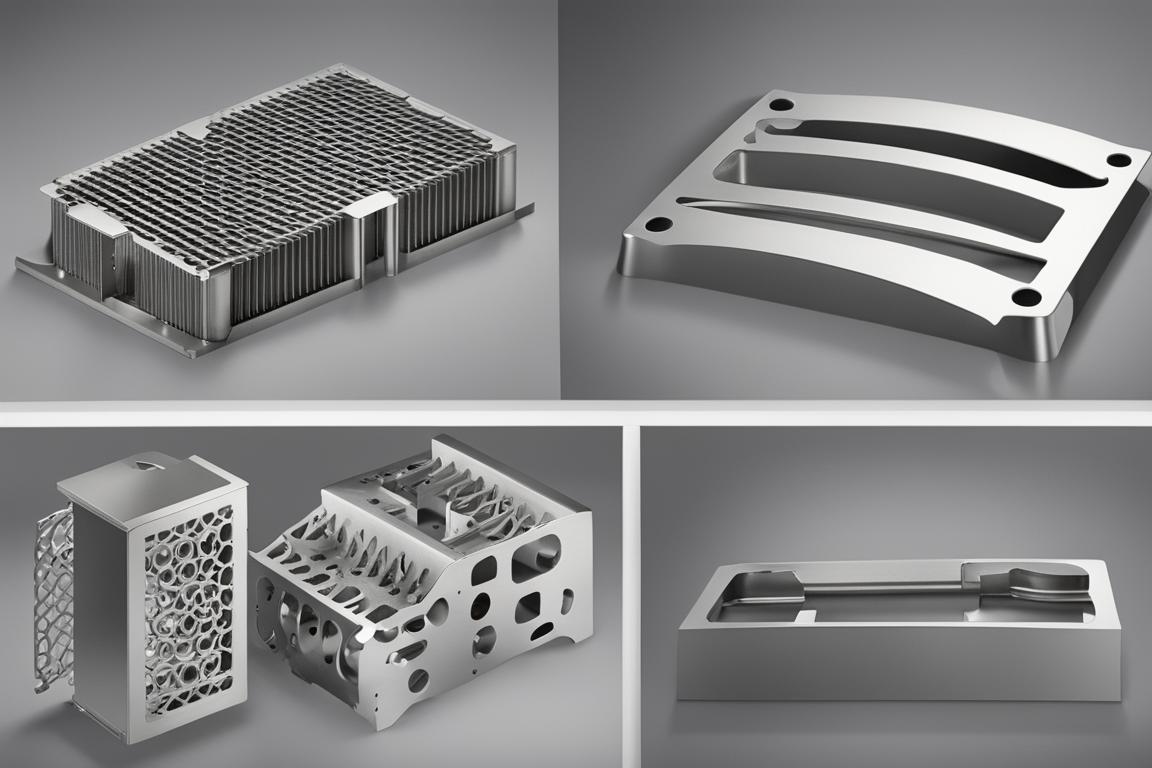

Metal fabricators serve the electronics industry by producing high-precision enclosures, heat sinks, and components that enable the performance and reliability of electronic devices and systems.

Medical Device Manufacturing and Metal Fabrication

In medical device manufacturing, metal fabricators contribute to the production of critical components, instruments, and implants that uphold the quality and safety standards essential to healthcare advancements.

Case Studies Demonstrating Metal Fabricators’ Contributions

Case studies showcasing the contributions of metal fabricators in diverse industry applications serve as compelling demonstrations of their expertise, innovation, and impact on advancing technological frontiers.

The future of metal fabrication is poised for remarkable evolution, driven by emerging trends and transformative technologies that will redefine the role of metal fabricators.

The Future of Metal Fabrication

Emerging Trends and Technologies

The future of metal fabrication is shaped by emerging trends such as additive manufacturing, automation, and digital integration, presenting new opportunities for metal fabricators to expand their capabilities and deliver innovative solutions.

Impact on the Role of Metal Fabricators

The evolving landscape of metal fabrication will impact the role of metal fabricators, necessitating the acquisition of new skills, adoption of advanced technologies, and proactive adaptation to changing industry dynamics.

Potential of 3D Metal Printing and Smart Manufacturing

3D metal printing and smart manufacturing hold immense potential for revolutionizing metal fabrication, offering unprecedented design freedom, material efficiency, and on-demand production capabilities.

As the metal fabrication industry continues to evolve, metal fabricators remain at the forefront of innovation, embracing new technologies and driving the ongoing evolution of the niche.

Conclusion

Metal fabricators play an essential role in precision sheet metal fabrication, upholding the highest standards of quality, precision, and customization. As the industry evolves, metal fabricators are well-positioned to seize new opportunities, expand their capabilities, and contribute to the ongoing advancement of precision sheet metal fabrication.

In conclusion, the impact of metal fabricators on precision sheet metal fabrication is a testament to their expertise, innovation, and dedication to delivering excellence in every fabricated component. As the industry embraces transformative technologies and explores new frontiers, metal fabricators will continue to be indispensable architects of precision and quality in metal fabrication.

For more information on metal fabrication and the latest industry trends, visit our blog on metal fabricators and explore the diverse facets of custom metal fabrication. If you have any questions or need assistance with your metal fabrication needs, please don’t hesitate to contact us. Remember, precision and quality go hand in hand in the world of metal fabrication, and metal fabricators are the artisans who bring these principles to life with unwavering expertise and dedication.