What You’ll Learn about Metal Fabrication

- The scope and importance of precision sheet metal fabrication in various industries.

- Different cutting, forming, bending, welding, and finishing processes used in metal fabrication.

- The role of advanced technologies, automation, and future trends in metal fabrication.

Metal fabrication is a crucial process that involves shaping, cutting, and assembling metal to create diverse products. Have you ever wondered how intricate metal components used in aerospace, automotive, electronics, and healthcare equipment are manufactured? Precision sheet metal fabrication plays a pivotal role in creating these high-quality components, and in this article, we will demystify the intricate world of metal fabrication, shedding light on its fundamental processes, materials, techniques, and its evolving landscape in the digital era.

Definition and Scope of Metal Fabrication

Metal fabrication encompasses a wide array of processes, including cutting, forming, welding, and finishing, to transform raw metal materials into finished products. It involves a blend of art and science, requiring meticulous attention to detail and advanced technical expertise. Precision sheet metal fabrication specifically focuses on the creation of high-quality, accurate, and intricate metal components used in various industries.

Importance of Precision Sheet Metal Fabrication in Various Industries

Precision sheet metal fabrication is integral to a multitude of industries due to its ability to produce custom, high-strength, and durable parts. From aircraft components that demand high precision to intricate medical devices, the importance of precision metal fabrication is undeniable. It ensures that products meet stringent quality standards and precise specifications, making it indispensable across diverse sectors.

Overview of Metal Fabrication Processes

The metal fabrication process involves several key stages, including cutting, forming, welding, and finishing. Each stage requires specialized techniques and equipment to manipulate metal into the desired shape and form. These processes are not only vital for creating functional components but also for achieving aesthetically pleasing and durable finishes.

Materials Used in Metal Fabrication

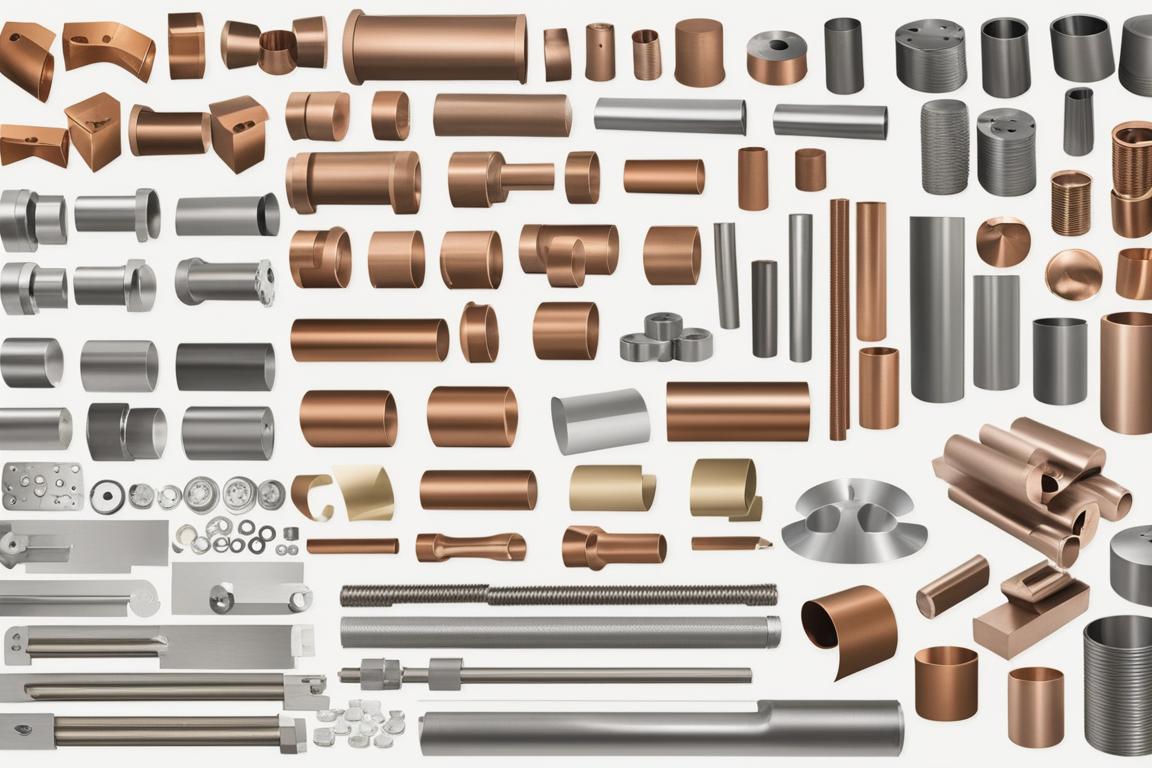

Types of Metals and Alloys Used in Fabrication

Metal fabrication involves working with an extensive range of metals and alloys, each with unique properties and characteristics. Common materials include stainless steel, aluminum, and copper, known for their versatility, strength, and corrosion resistance. Furthermore, specialty alloys such as titanium and nickel-based alloys are utilized for applications requiring exceptional strength and heat resistance.

Properties and Characteristics of Stainless Steel, Aluminum, and Copper

Stainless steel is renowned for its corrosion resistance, making it suitable for a wide range of applications, from medical equipment to architectural structures. Aluminum, on the other hand, is lightweight and exhibits excellent conductivity, making it ideal for aerospace and automotive components. Copper, known for its electrical conductivity, finds application in electronics and telecommunications.

Considerations for Material Selection in Metal Fabrication

Selecting the right material is critical in metal fabrication to ensure that the final product meets performance and regulatory requirements. Factors such as mechanical properties, corrosion resistance, and cost-effectiveness play a vital role in material selection. Moreover, environmental considerations and recyclability are increasingly important in modern metal fabrication processes.

| Metal/Alloy | Properties and Characteristics | Applications |

|---|---|---|

| Stainless Steel | Corrosion resistance, strength, versatility | Medical equipment, architectural structures |

| Aluminum | Lightweight, excellent conductivity, corrosion resistance | Aerospace, automotive components |

| Copper | Electrical conductivity, malleability, corrosion resistance | Electronics, telecommunications |

| Titanium | Exceptional strength, heat resistance, lightweight | Aerospace, medical implants |

| Nickel-based Alloys | High temperature resistance, corrosion resistance, strength | Gas turbines, chemical processing |

Cutting Processes in Metal Fabrication

Overview of Cutting Techniques: Laser, Waterjet, Plasma

Cutting is a fundamental process in metal fabrication, and several techniques are employed to achieve precision and accuracy. Laser cutting utilizes a high-powered laser to vaporize or melt the material, offering exceptional precision and minimal material wastage. Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to cut through various metals, while plasma cutting uses a high-velocity jet of ionized gas to melt and sever metal.

Advantages and Limitations of Different Cutting Methods

Each cutting method has its advantages and limitations. Laser cutting, for instance, offers high precision and minimal heat-affected zones but may be unsuitable for thicker materials. Waterjet cutting is highly versatile and environmentally friendly but may not be as efficient for high-volume production. Plasma cutting, on the other hand, is well-suited for cutting thicker materials but may produce a wider heat-affected zone.

Best Practices for Precision Cutting in Metal Fabrication

To achieve optimal results in precision cutting, factors such as material thickness, cutting speed, and nozzle selection must be carefully considered. Additionally, maintaining the cutting equipment and adhering to safety protocols is crucial for ensuring consistent and high-quality cuts. The choice of cutting method depends on the specific requirements of the project, including material type, thickness, and intricacy of the design.

Forming and Bending in Metal Fabrication

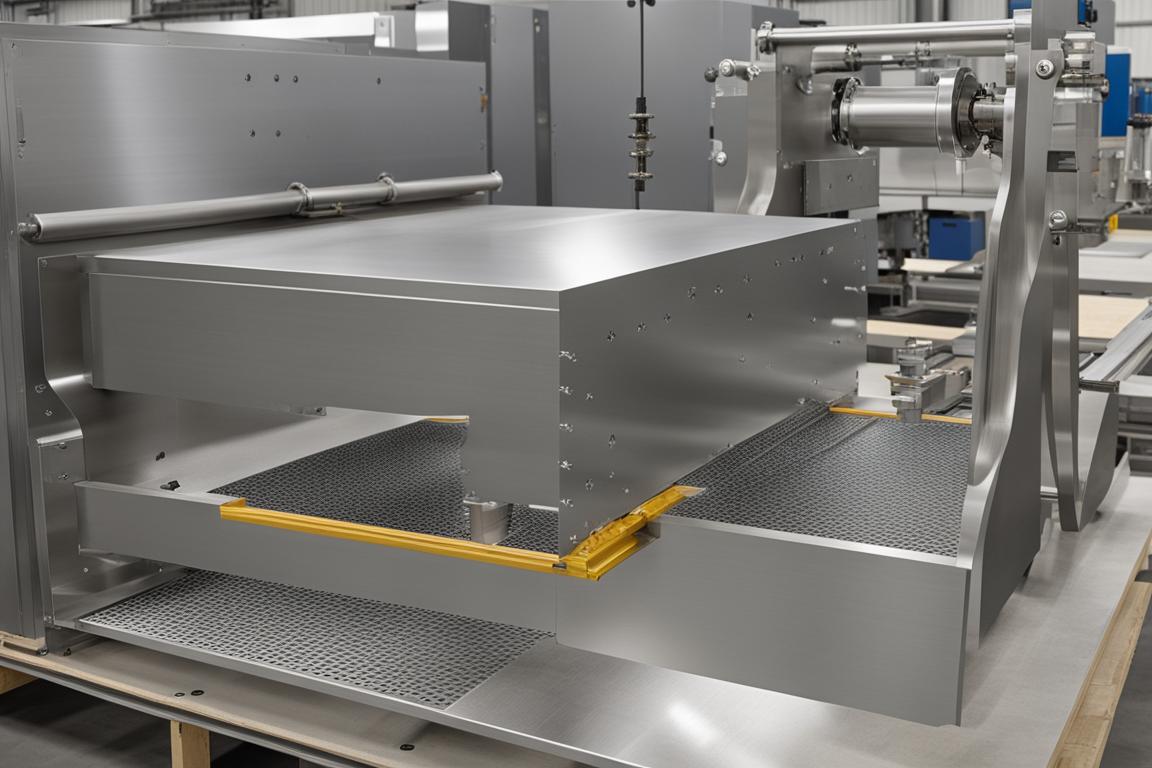

Techniques and Equipment for Forming and Bending Metal Sheets

Forming and bending are essential processes in metal fabrication, allowing the creation of complex shapes and structures. Techniques such as press brake forming and roll forming, coupled with specialized tooling and dies, enable the precise manipulation of metal sheets. Advanced CNC press brakes and roll forming machines have further streamlined the forming and bending processes, ensuring accuracy and repeatability.

Factors Affecting Metal Forming and Bending Processes

The successful forming and bending of metal sheets depend on various factors, including material ductility, tooling design, and the application of appropriate bending forces. Understanding the material’s behavior under stress and strain is critical in achieving the desired shape without compromising material integrity. Factors such as springback and material thickness variations also influence the accuracy of formed components.

Practical Application and Case Studies

To provide practical insights into the world of precision sheet metal fabrication, let’s explore a few case studies showcasing real-world applications and the impact of metal fabrication processes. These case studies will highlight the critical role of precision sheet metal fabrication in delivering innovative solutions across industries, demonstrating the practical relevance of the discussed processes.

In conclusion, precision sheet metal fabrication is a multifaceted discipline that underpins the production of high-quality metal components across diverse industries. By understanding the fundamental processes, materials, and techniques involved in metal fabrication, manufacturers can leverage this knowledge to create innovative and reliable products that meet the ever-evolving demands of the modern market.

By integrating practical experiences and real-world examples, this article aims to provide a comprehensive understanding of precision sheet metal fabrication, offering valuable insights into its application and impact in today’s industrial landscape.

Frequently Asked Questions

Q: Who provides precision sheet metal fabrication services?

A: Precision sheet metal fabrication services are provided by specialized metal fabrication companies.

Q: What is precision sheet metal fabrication?

A: Precision sheet metal fabrication is the process of cutting, bending, and assembling sheet metal to create high-quality, custom parts and products.

Q: How is precision sheet metal fabrication different from regular fabrication?

A: Precision sheet metal fabrication involves tighter tolerances and specialized techniques to create intricate, accurate components.

Q: Can precision sheet metal fabrication handle complex designs?

A: Yes, precision sheet metal fabrication can handle complex designs with advanced equipment and skilled technicians.

Q: What are the advantages of precision sheet metal fabrication?

A: Precision sheet metal fabrication offers high accuracy, repeatability, and the ability to create intricate parts for various industries.

Q: Isn’t precision sheet metal fabrication expensive?

A: While precision sheet metal fabrication may have higher initial costs, its accuracy and quality often lead to cost savings in the long run.