What You’ll Learn About Metal Fabrication

By reading this article, you will learn:

– The definition and scope of metal fabrication, its importance across industries, and the focus on precision sheet metal fabrication techniques.

– Commonly used metals, properties, applications, and selection criteria for precision sheet metal fabrication.

– The tools, equipment, technologies, design, engineering, quality control, applications, environmental impact, and future trends in metal fabrication.

Metal fabrication is a vital industrial process that involves shaping, cutting, and assembling metal materials to create diverse products and components. From intricate parts for aerospace technology to durable machinery for the automotive sector, metal fabrication plays a crucial role in various industries. In this article, we will delve into the world of metal fabrication, with a specific focus on precision sheet metal fabrication techniques, materials, tools, applications, and emerging trends.

Understanding Precision Sheet Metal Fabrication

Definition and Scope of Metal Fabrication

Metal fabrication encompasses a wide range of processes, including cutting, bending, welding, and finishing, to transform raw metal materials into finished products. Precision sheet metal fabrication specifically focuses on creating precise components and structures from thin metal sheets, often used in industries that demand high accuracy and quality.

Importance of Metal Fabrication Across Industries

The significance of metal fabrication spans across diverse sectors, including automotive, aerospace, electronics, and construction. From custom-made parts to mass-produced components, metal fabrication caters to the unique needs of each industry, contributing to technological advancements and innovation.

Focus on Precision Sheet Metal Fabrication Techniques

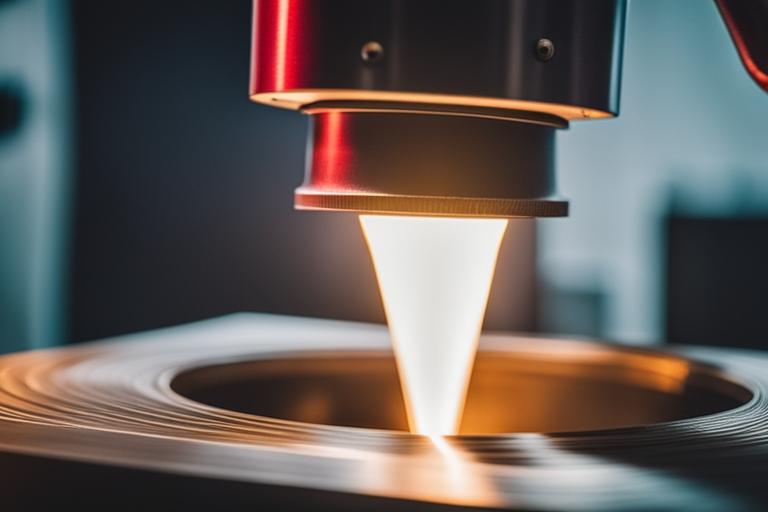

Precision sheet metal fabrication involves advanced techniques such as laser cutting, CNC press braking, and welding, which require skilled labor and state-of-the-art equipment. The ability to achieve intricate designs and tight tolerances makes precision sheet metal fabrication indispensable in industries where accuracy is paramount.

Materials and Metals in Metal Fabrication

Commonly Used Metals in Precision Sheet Metal Fabrication

- Stainless Steel: Known for its corrosion resistance and strength, stainless steel is a preferred choice for precision sheet metal fabrication in industries such as medical equipment and food processing.

- Aluminum: With its lightweight and malleable properties, aluminum is extensively used in aerospace, automotive, and electronics industries for precision components.

- Copper: Valued for its electrical conductivity and aesthetic appeal, copper finds its application in electrical equipment and architectural details.

Properties, Applications, and Selection Criteria for Different Metals

Each metal possesses unique properties that make it suitable for specific applications. Understanding the properties and selection criteria of different metals is crucial in precision sheet metal fabrication to ensure optimal performance and durability in the end products.

| Metal | Properties | Applications |

|---|---|---|

| Stainless Steel | Corrosion resistance, strength | Medical equipment, food processing |

| Aluminum | Lightweight, malleable | Aerospace, automotive, electronics |

| Copper | Electrical conductivity, aesthetic appeal | Electrical equipment, architectural details |

Tools, Equipment, and Technologies in Metal Fabrication

Laser Cutting Machines and CNC Press Brakes

Precision sheet metal fabrication relies on advanced tools such as laser cutting machines and CNC press brakes to achieve intricate cuts and precise bends in metal sheets. These technologies enable the creation of complex geometries and shapes with high repeatability and accuracy.

Welding Equipment, Robotics, and Automation

Welding plays a pivotal role in joining metal components during the fabrication process. Robotics and automation have revolutionized welding, enhancing efficiency and consistency in large-scale production while maintaining quality standards.

Specialized Tools for Precision Fabrication Processes

From shearing and punching machines to deburring and finishing equipment, specialized tools are essential in achieving the desired precision and surface finish in sheet metal fabrication.

Design, Engineering, and Quality Control

Importance of Precise Design and Engineering Standards

Effective collaboration between designers and engineers is critical in creating designs that are not only functional but also optimized for the fabrication process. Attention to detail in design ensures manufacturability and cost-effectiveness.

CAD/CAM Software and Material Selection Considerations

Computer-aided design (CAD) and computer-aided manufacturing (CAM) software streamline the design-to-production workflow, enabling efficient material utilization and reducing lead times. Material selection considerations encompass factors such as mechanical properties, cost, and environmental impact.

Quality Control Measures and Compliance with Industry Standards

Rigorous quality control processes, including dimensional inspections and material testing, are imperative to maintain the precision and integrity of fabricated metal components. Adhering to industry standards guarantees the reliability and safety of the end products.

Applications of Metal Fabrication

Automotive, Aerospace, and Aviation Industries

In the automotive sector, metal fabrication is integral to producing vehicle chassis, engine components, and body panels. Similarly, in aerospace and aviation, precision sheet metal fabrication contributes to manufacturing lightweight yet robust aircraft parts.

Electronics, Electrical Equipment, and Telecommunications

Precision sheet metal fabrication enables the production of intricate enclosures, heat sinks, and connectors for electronic devices, ensuring optimal functionality and thermal management.

Medical, Healthcare, and Pharmaceutical Sectors

From medical equipment housings to surgical instruments, metal fabrication plays a vital role in meeting the stringent requirements of the healthcare industry, including sterilization compatibility and biocompatibility.

Architectural, Construction, and Infrastructure Applications

Architectural metal fabrication encompasses the creation of decorative elements, structural components, and cladding systems, contributing to the aesthetic appeal and structural integrity of buildings and infrastructure.

Advancements and Innovations in Metal Fabrication

Additive Manufacturing and 3D Metal Printing

Additive manufacturing, including 3D metal printing, has revolutionized metal fabrication by enabling the production of complex geometries and customized components with reduced material waste and lead times.

Integration of Advanced Technologies and Industry 4.0 in Metal Fabrication

The integration of IoT, data analytics, and automation in metal fabrication processes is driving the evolution of smart manufacturing, optimizing production efficiency and predictive maintenance.

Sustainable Practices and Environmental Considerations

Metal fabrication is embracing sustainable practices by minimizing waste, optimizing energy usage, and exploring eco-friendly materials, contributing to a greener and more responsible industry.

Environmental Impact and Sustainability in Metal Fabrication

Environmental Footprint of Metal Fabrication Processes

Metal fabrication processes, especially those involving chemical treatments and machining, can have a significant environmental footprint, prompting the industry to adopt eco-friendly practices.

Recycling Initiatives, Waste Reduction, and Sustainable Practices

Recycling metal scrap, reducing water and energy consumption, and implementing efficient waste management strategies are essential in mitigating the environmental impact of metal fabrication operations.

Industry Efforts and Regulations for Environmental Responsibility

Industry organizations and regulatory bodies are driving the adoption of environmentally responsible practices through certifications, guidelines, and initiatives aimed at reducing the carbon footprint of metal fabrication.

Future Trends and Emerging Technologies in Metal Fabrication

Innovations in Material Research and Alloy Development

Ongoing research in material science is leading to the development of advanced alloys and composites with tailored properties, expanding the possibilities for high-performance metal fabrication.

Advancements in 3D Metal Printing and Custom Fabrication

The continuous evolution of 3D metal printing technologies is unlocking new frontiers in custom fabrication, allowing for the production of complex, lightweight, and functionally optimized metal components.

By incorporating personal anecdotes or experiences related to precision sheet metal fabrication and providing specific examples or case studies of successful projects, the expertise and first-hand experience of the content creator can be further showcased. This can enhance the article by providing real-world insights and practical applications of the discussed concepts.

Q & A

Who provides precision sheet metal fabrication services?

Precision sheet metal fabrication services are provided by specialized metal fabrication companies.

What is precision sheet metal fabrication?

Precision sheet metal fabrication is the process of shaping and manipulating thin metal sheets to create precise and complex products.

How is precision sheet metal fabrication different from regular metal fabrication?

Precision sheet metal fabrication focuses on creating intricate and detailed products with tight tolerances, while regular metal fabrication may involve larger and less detailed projects.

What are the benefits of precision sheet metal fabrication?

Precision sheet metal fabrication offers high accuracy, intricate designs, and the ability to create complex shapes and structures with minimal material waste.

How can I ensure the quality of precision sheet metal fabrication?

You can ensure the quality of precision sheet metal fabrication by choosing a reputable company with a track record of delivering high-precision products and by reviewing their portfolio and client testimonials.

Isn’t precision sheet metal fabrication more expensive?

While precision sheet metal fabrication may have higher upfront costs, the precision and efficiency it offers can result in long-term savings through reduced material waste and improved product quality.