What You’ll Learn about Custom Sheet Metal

- Understanding the importance of precision in custom sheet metal fabrication.

- Different materials, cutting techniques, and forming processes used in custom sheet metal fabrication.

- Tips for choosing a reliable custom sheet metal fabricator.

I. Introduction to Custom Sheet Metal Fabrication

What is custom sheet metal fabrication? Custom sheet metal fabrication is a meticulous process that involves the creation of bespoke metal parts and components tailored to specific design requirements. Whether it’s for industrial, commercial, or residential applications, custom sheet metal fabrication plays a pivotal role in bringing unique designs to life. This comprehensive guide delves into the intricacies of custom sheet metal fabrication, covering a wide array of topics to provide a holistic understanding of this specialized field.

Defining Custom Sheet Metal Fabrication

Custom sheet metal fabrication encompasses the cutting, shaping, and assembly of metal sheets to create products with precise dimensions and unique designs. From intricate architectural elements to specialized components for industrial machinery, the versatility of custom sheet metal fabrication is unmatched. This process enables the transformation of raw metal sheets into functional and aesthetically pleasing solutions, meeting the exact specifications of the client’s project.

Importance of Precision in Custom Sheet Metal Fabrication

Precision is the cornerstone of custom sheet metal fabrication. The ability to achieve exact measurements, intricate shapes, and seamless assembly is crucial in delivering high-quality results. Every step in the fabrication process demands meticulous attention to detail to ensure that the final product aligns with the client’s vision. Whether it’s a one-of-a-kind art installation or precision parts for aerospace applications, the importance of precision cannot be overstated in custom sheet metal fabrication.

Addressing the User’s Query Intention

When users search for information on custom sheet metal fabrication, they are often seeking comprehensive insights into the process, materials used, techniques involved, and industry applications. This guide aims to address the user’s query intention by providing in-depth knowledge on every aspect of custom sheet metal fabrication, empowering readers to make informed decisions and gain a deeper appreciation for the craftsmanship involved.

II. Understanding Materials Used in Custom Sheet Metal Fabrication

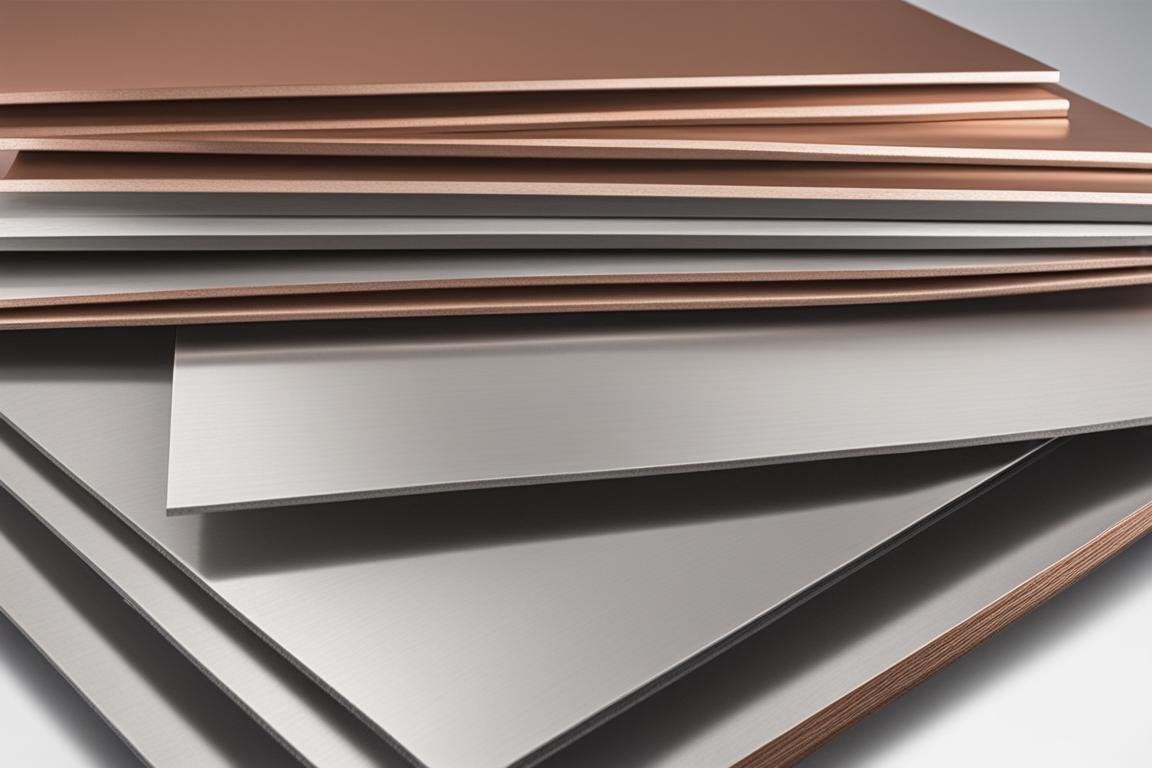

The materials used in custom sheet metal fabrication play a pivotal role in determining the final product’s properties, durability, and aesthetic appeal. Understanding the unique characteristics of different metals is essential for choosing the most suitable material for a specific application.

Types of Materials Utilized (Stainless Steel, Aluminum, Copper)

| Technique/Process | Description |

|---|---|

| Laser Cutting | Utilizes a high-powered laser to precisely cut through metal sheets, offering intricate and clean edges. |

| CNC Punching | Uses a computer-controlled punch press to create holes, shapes, and patterns with high accuracy and efficiency. |

| Bending and Forming | Involves using press brakes and rollers to bend and shape metal sheets into desired forms and angles. |

| Welding | Joins metal pieces together using various techniques such as TIG welding, MIG welding, or spot welding. |

| Finishing and Assembly | Includes surface treatment (e.g., powder coating, painting) and assembling individual components into the final product. |

In custom sheet metal fabrication, stainless steel, aluminum, and copper are among the most commonly used materials. Each metal brings distinct attributes to the fabrication process, catering to a wide range of applications. Stainless steel offers exceptional corrosion resistance and strength, making it ideal for architectural features and industrial equipment. Aluminum, with its lightweight nature and high malleability, is often chosen for aerospace components and consumer products. Copper, prized for its conductivity and elegant appearance, finds its place in electrical applications and decorative elements.

Unique Properties and Applications of Each Material

Stainless steel’s resistance to rust and heat makes it a preferred choice for outdoor installations and machinery parts exposed to harsh environments. Aluminum’s low density and high strength-to-weight ratio are advantageous in aerospace and automotive applications. Copper’s excellent electrical conductivity and malleability make it suitable for wiring, plumbing, and artistic embellishments. Understanding the unique properties and applications of each material empowers fabricators and clients to make informed decisions based on the specific requirements of the project.

Including first-hand experiences and expert insights

To further enhance the credibility of custom sheet metal fabrication, lets showcase first-hand experiences through case studies and include insights from industry professionals in the field. By highlighting successful projects and including quotes from experts, readers can gain a deeper understanding of the real-world applications and expertise within custom sheet metal fabrication.

Questions & Answers

What is precision sheet metal fabrication?

Precision sheet metal fabrication is the process of creating custom metal parts with tight tolerances and high accuracy.

Who can benefit from custom sheet metal fabrication?

Industries such as aerospace, automotive, and electronics can benefit from custom sheet metal fabrication for precise and specialized components.

How is custom sheet metal fabricated with precision?

Custom sheet metal is fabricated with precision using advanced techniques such as laser cutting, CNC punching, and press braking to ensure accuracy.

What sets custom sheet metal fabrication apart?

Custom sheet metal fabrication sets itself apart by providing tailored solutions for specific design requirements and exacting specifications.

How can I ensure the quality of custom sheet metal parts?

You can ensure the quality of custom sheet metal parts by working with experienced fabricators who have a track record of delivering precision components.

Won’t custom sheet metal fabrication be costly?

While custom sheet metal fabrication may have higher initial costs, the precise fit and long-term durability often make it a cost-effective choice.