What You’ll Learn About Custom Laser Cutting Services

By reading this article, you will learn:

– The significance and applications of custom laser cutting services.

– The advantages, customization, and quality standards of custom laser cutting services.

– The industry-specific applications, choosing the right provider, and future trends in custom laser cutting.

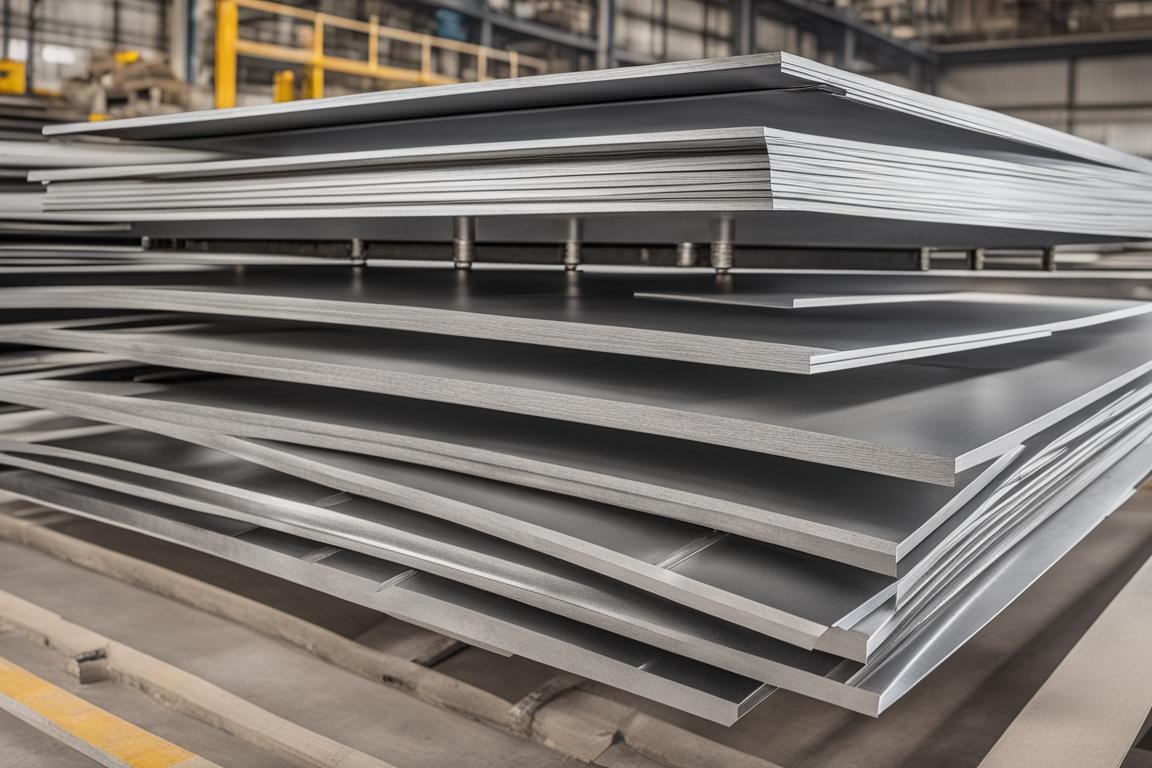

Custom laser cutting services have significantly transformed the landscape of precision sheet metal fabrication. This advanced manufacturing technique offers unparalleled precision and customization, catering to a wide array of industries and applications, such as aerospace, automotive, electronics, and medical devices. The demand for intricate and bespoke metal components continues to rise, making the significance of custom laser cutting in delivering high-quality, tailored solutions undeniable.

Definition and Significance of Custom Laser Cutting

Custom laser cutting involves the use of a high-powered laser to precisely cut, engrave, or mark various materials, including metals, plastics, and wood. The focal point of the laser beam melts, burns, or vaporizes the material, resulting in intricately detailed cuts and designs. The technique’s significance lies in its ability to produce complex geometries and intricate patterns with exceptional accuracy, making it indispensable in industries requiring superior precision and customization.

Applications and Industries Utilizing Custom Laser Cutting Services

Industries such as aerospace, automotive, electronics, and medical devices rely heavily on custom laser cutting services to fabricate intricate components, enclosures, and specialized parts. For instance, in the aerospace industry, custom laser cutting is used for manufacturing lightweight yet durable components that meet stringent performance standards. Additionally, the architectural and jewelry industries leverage laser cutting for creating intricate designs and decorative elements. The versatility and precision of custom laser cutting make it indispensable across a spectrum of applications, catering to diverse industry needs.

Understanding the Process of Custom Laser Cutting

The process of custom laser cutting involves a series of intricate steps, beginning with digital design and culminating in the precise fabrication of the desired components.

Step-by-Step Guide to Custom Laser Cutting

- Digital Design: The process commences with creating a digital design of the component to be fabricated, specifying precise dimensions and intricate details.

- Material Preparation: The chosen material, often sheet metal, is prepared and positioned within the laser cutting machine, ensuring stability and accuracy during the cutting process.

- Laser Cutting: The high-powered laser beam is precisely directed according to the digital design, resulting in the accurate cutting or engraving of the material.

- Quality Inspection: Following the cutting process, rigorous quality inspections are conducted to ensure the components meet the specified design tolerances and quality standards.

Materials Suitable for Custom Laser Cutting and Precision Levels

Custom laser cutting services are adept at working with a diverse range of materials, including stainless steel, aluminum, copper, and various alloys. The precision levels achievable through laser cutting are exceptional, allowing for intricate designs and complex geometries to be realized with unparalleled accuracy.

| Advantages | Description |

|---|---|

| Increased Accuracy and Precision | Delivering unparalleled accuracy and precision, enabling the fabrication of intricate components with tight tolerances and fine details. |

| Reduction of Material Waste and Environmental Impact | Minimizing material wastage, optimizing resource utilization, and reducing the environmental impact of manufacturing processes. |

| Accelerated Production Times | Contributing to accelerated production times, facilitating faster turnaround for fabricated components. |

| Cost-Effectiveness and Versatility in Fabrication | Offering cost-effective solutions by minimizing material wastage, reducing the need for extensive manual labor, and streamlining the fabrication process. |

Advantages of Custom Laser Cutting Services

The adoption of custom laser cutting services offers a myriad of advantages, revolutionizing precision sheet metal fabrication and manufacturing processes.

Increased Accuracy and Precision

Custom laser cutting excels in delivering unparalleled accuracy and precision, enabling the fabrication of intricate components with tight tolerances and fine details. This level of precision is crucial in industries where the functionality and performance of components are paramount.

Reduction of Material Waste and Environmental Impact

The precision of laser cutting minimizes material wastage, optimizing resource utilization and reducing the environmental impact of manufacturing processes. This eco-friendly approach aligns with sustainable manufacturing practices, making it an attractive option for environmentally conscious industries.

Accelerated Production Times

The efficiency of custom laser cutting processes contributes to accelerated production times, facilitating faster turnaround for fabricated components. This rapid production capability provides a competitive edge in meeting stringent project timelines and customer demands.

Cost-Effectiveness and Versatility in Fabrication

Custom laser cutting services offer cost-effective solutions by minimizing material wastage, reducing the need for extensive manual labor, and streamlining the fabrication process. Moreover, the versatility of laser cutting allows for the production of diverse components with varying complexities, consolidating manufacturing operations.

Customization and Design Flexibility in Laser Cutting

The inherent flexibility and customization capabilities of custom laser cutting services are instrumental in empowering design innovation and tailored solutions across multiple industries.

Flexibility in Design Offered by Custom Laser Cutting Services

The ability to translate intricate digital designs into precise, tangible components underscores the unparalleled design flexibility offered by custom laser cutting services. This adaptability is pivotal in realizing complex geometries and customized features in fabricated parts.

Prototype Development and Iterative Design Processes

Custom laser cutting facilitates rapid prototyping and iterative design refinement, allowing for the creation and evaluation of prototypes with exceptional precision. This iterative approach accelerates the development cycle, enabling swift design iterations and enhancements.

In conclusion, custom laser cutting services have revolutionized precision sheet metal fabrication, offering unmatched accuracy, customization, and efficiency. Real-life examples showcase the impact of custom laser cutting in diverse industries, illustrating its pivotal role in delivering high-quality, tailored solutions. Industry professionals and experts emphasize the significance of custom laser cutting, affirming its position as a cornerstone of advanced manufacturing techniques.

FAQ

Q.Who provides custom laser cutting services?

A.Precision sheet metal fabrication companies offer custom laser cutting services.

Q.What materials can be used with custom laser cutting?

A.Custom laser cutting can be used with various materials such as steel, aluminum, and titanium.

Q.How does custom laser cutting work?

A.Custom laser cutting works by using a high-powered laser to precisely cut through the chosen material.

Q.Can custom laser cutting services accommodate specific designs?

A.Yes, custom laser cutting services can accommodate specific designs to meet your exact requirements.

Q.What are the benefits of custom laser cutting services?

A.Custom laser cutting services offer high precision, intricate detailing, and efficient production.

Q.How can I ensure the quality of custom laser cutting services?

A.To ensure quality, look for a company with a proven track record and positive customer reviews in precision sheet metal fabrication.